Lost-wax casting uses wax to create intricate molds, while lost-foam casting uses foam materials to shape the parts. Wax molds create smooth surfaces and are suitable for small, complex parts. Foam molds are suitable for large or simple shapes and are less expensive. Each precision casting method uses different materials and steps. Understanding these differences helps people choose the best process for their projects.

Principaux enseignements

- Lost-wax casting is suitable for small, intricate parts. It is ideal when you need smooth surfaces and high precision. Lost-foam casting is better suited for large, simple shapes. It is generally less expensive and faster. You should choose the appropriate casting method based on the size, shape, material, and quantity of the part. Lost-wax casting uses wax molds and ceramic molds. Lost-foam casting uses foam molds and sand molds. KEMING can perform both casting methods. They will help customers choose the process best suited for their projects.

Processus de moulage à la cire perdue

Lost-wax casting can produce very precise parts. It also produces smooth surfaces. Many industries prefer this method because of its remarkable results.

Lost Wax Casting Pattern Creation

The first step is to make a model. Manufacturers use either regular wax or special 3D printing wax. Each type has its own advantages, as shown in the table below:

| Type de matériau | Avantages |

|---|---|

| Conventional wax patterns | Costs less for many parts, makes smooth surfaces, good for repeating parts with tools. |

| 3D Printing Castable Wax/Photosensitive Polymer | No need for hard tools, makes tricky shapes, quick changes, and custom parts for patients. |

These options help designers create intricate and repeatable parts.

Lost Wax Casting Mold Formation

Next, workers create the mold. They dip the wax model into a ceramic slurry. They need to repeat this process multiple times to form a robust outer shell. The table below shows the steps involved in this process:

| Aspect | Description |

|---|---|

| Matériau du moule | Ceramic slurry forms a tough outer layer. |

| Technique | Repeated dipping makes the shell thick and strong. |

| Impact on Final Product | A high-quality mold shell allows for a smooth surface and precise dimensions. |

| Processus de déparaffinage | The wax is heated and melted, leaving perfect mold space. |

| Types de métaux | Suitable for various metals including bronze, stainless steel, and aluminum. |

This process helps ensure the precision and smoothness of the final parts.

Lost Wax Casting Applications

Lost-wax casting is widely used in numerous industries. It is ideal for manufacturing strong and complex parts. Here are some industries that use this process:

- Automotive: Manufacturing precise parts and complex shapes

- Aerospace: Manufacturing lightweight, strong, and delicate parts

- Oil and Gas: Manufacturing parts suitable for high temperatures and harsh environments

- Food Processing: Manufacturing clean and functional parts

- General Engineering: Applied to a variety of different fields

The railroad and shipbuilding industries also use lost-wax casting. They require precise and strong parts. This process is the preferred choice when precision and strength are critical.

Lost Foam Casting Process

Foam Pattern Use

Lost foam casting begins with the creation of foam molds. Workers design the molds using CAD software. They shape the foam using CNC machine tools or 3D printers. Most foundries choose EPS foam because it is inexpensive and lightweight. EPS foam is easy to mold and burns cleanly. This simplifies the casting process. XPS foam is heavier and has a longer lifespan. However, XPS foam is more difficult to cut and recycle. The table below shows the differences between EPS and XPS foam:

| Fonctionnalité | EPS (polystyrène expansé) | XPS (polystyrène extrudé) |

|---|---|---|

| Coût | Plus bas | Plus élevé |

| Poids | Plus léger | Plus lourd |

| Durabilité | Plus fragile | Plus durable |

| Recyclage | Plus facile | Plus difficile |

EPS foam is often chosen because it holds its shape well. It also helps workers create precise parts.

Lost Foam Casting Mold Preparation

After making the foam mold, workers add gating and venting channels. They apply a special slurry to the foam. This helps enhance the strength and smoothness of the mold. The mold is placed in the mold. Workers fill it tightly with sand. Silica sand is widely used because of its stability and availability. Sometimes, zirconium sand helps to better control the temperature. Bentonite helps the sand bind together better. The table below lists the materials used in the mold:

| Type de matériau | Description |

|---|---|

| Polystyrène | Light, stable, and burns away cleanly. |

| Boues réfractaires | Makes the mold stronger and smoother. |

| Sable de silice | Common, stable, and easy to get. |

| Sable de zircon | Helps control heat and stops mold from expanding. |

| Argile bentonite | Makes sand stick together for a strong mold. |

These steps contribute to the production of precise and robust parts in lost foam casting.

Applications de la coulée de mousse perdue

Lost foam casting technology is widely used in numerous industries. Automakers use it to manufacture engine blocks and housings; aerospace and defense companies use it to manufacture blades and frames; equipment manufacturers use it to manufacture valves and pumps; artists and architects use it to create sculptures and doors; and farmers use it to manufacture tractor engines and irrigation valves. Lost foam casting is flexible and highly precise, suitable for a variety of casting operations.

Tip: Lost foam casting is best suited for large or simple shapes. It is especially suitable when cost and speed are critical.

Comparative Analysis of Lost Wax and Lost Foam Casting Methods

Comparative analysis helps engineers and designers choose the best casting method. KEMING offers both lost foam casting and lost foam molding processes, providing customers with options for different operations. This section will introduce the main differences between the two processes in terms of steps, tools, materials, and costs.

Étapes du processus

The steps involved in lost foam casting and lost foam molding differ. They also differ in the model materials used and the workflow. Lost foam casting uses wax patterns, while lost foam molding uses foam patterns. These differences affect the number of process steps and the risk of defects. Production scale and flexibility also differ.

| Étape | Cire perdue | Moulage en mousse perdue |

|---|---|---|

| Model Materials | Cire | Polystyrène expansé (EPS) |

| Création de motifs | Made using a mold | Sculpted or assembled from foam blocks |

| Shell Creation | Immersed in ceramic slurry and dried | Coated with refractory slurry and dried |

| Suppression du motif | Wax is melted away | Foam vaporizes during casting |

| Final Casting | Molten metal poured into ceramic mold | Molten metal fills void left by vaporized foam |

Lost wax casting involves more steps and requires intricate model making and shell shaping. This process produces very precise and smooth parts. Lost foam casting involves fewer steps and is faster and less expensive for some projects. The foam model disappears during metal pouring, meaning fewer steps are needed to remove the model.

Tooling and Materials

Molds and materials affect cost, production scale, and flexibility. They also affect the types of metals that can be used. Investment casting requires more complex wax models and ceramic shell molds. Foam casting uses simpler foam molds. This reduces mold costs for small to medium batch orders.

| Méthode de coulée | Tooling Complexity | Initial Tooling Cost | Compatibilité des matériaux | Limites |

|---|---|---|---|---|

| Cire perdue | More complex (wax and ceramic molds) | High for high-volume runs | Wide variety of metals and alloys | Pattern size may limit casting size |

| Moulage en mousse perdue | Simpler (foam patterns) | Lower for small/medium runs | Best for aluminum and cast iron | Foam must match molten metal compatibility |

Investment casting is suitable for a variety of metals, such as steel, bronze, and aluminum. This makes it suitable for many industries. Foam casting is commonly used for casting aluminum and cast iron parts. The foam mold must be highly compatible with the molten metal to avoid problems.

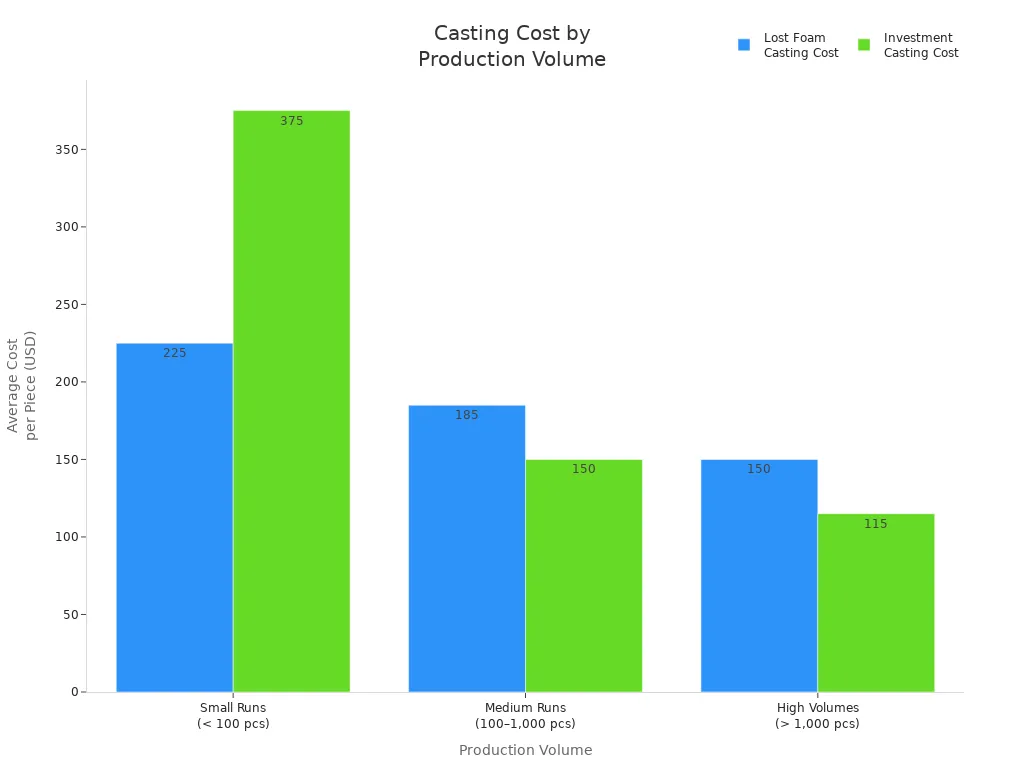

Comparaison des coûts

Cost is an important consideration when choosing a casting method. Lost foam casting typically has lower mold costs. Investment casting (also known as lost-wax casting) has higher initial costs, but may be more economical for mass production due to its high precision and repeatability.

| Volume de production | Lost Foam Casting Cost | Investment Casting Cost |

|---|---|---|

| Small Runs (< 100 pcs) | $150–$300 each | $250–$500 each |

| Medium Runs (100–1,000 pcs) | $120–$250 | $100–$200 |

| High Volumes (> 1,000 pcs) | $100–$200 | $80–$150 |

Lost foam casting is more economical for small to medium batch production. Investment casting is more suitable for large-volume production because mold costs can be spread. Both methods are suitable for many industries. The choice depends on the precision requirements of the parts, the number of parts required, and the materials used.

Note: KEMING has excellent skills in both lost-wax casting and foam casting, helping customers achieve optimal results. Customers can choose a high-precision or low-cost solution based on project requirements.

Lost Wax and Lost Foam Casting Surface Finish and Dimensional Accuracy

Lost Wax Casting Results

Investment casting is renowned for its extremely high precision. It produces parts with smooth surfaces and sharp details. Many companies choose this method when high-precision parts are required. This process can create thin-walled and complex shapes that are impossible to achieve with other methods.

- Investment casting can produce very precise and smooth-surfaced parts.

- It can handle complex designs and thin walls.

- Many industries use investment casting to manufacture parts that require precision and strength.

Aerospace and medical device manufacturers frequently use this process. They require parts with tight fits and smooth appearances. Investment casting consistently delivers the same excellent results for them.

Lost Foam Casting Results

Lost foam casting also provides good surface finish and precision. However, its precision is not as high as investment casting. This method is suitable for larger parts or situations where cost control is critical. The foam model is burned away, eliminating the need for draft angles. This helps in creating shapes that are difficult to achieve with other methods.

The table below shows the expected results of lost foam casting:

| Surface Finish (Ra μm) | Dimensional Tolerance (%) | Notes |

|---|---|---|

| 4 to 8 | ±0.4 to ±1.5 | Uses foam patterns and loose sand together. |

Lost foam casting is superior to wet sand casting, but not as smooth and precise as investment casting. It strikes a good balance between price and quality. Many companies use it for parts that do not require high precision but still need to ensure good performance.

Tip: If you need very precise and smooth parts, lost foam casting is the best choice. Lost foam casting is more suitable for larger or simpler parts to save time and cost.

Lost Wax and Lost Foam Casting Strengths and Limitations

Lost Wax Casting Pros and Cons

Lost foam casting is ideal for producing very smooth and precise parts. Many companies use this process when they need high-quality parts. The table below lists the advantages and limitations of investment casting:

Strengths of Lost Wax Casting:

- Excellente qualité de surface

- Precise dimensions

- Intricate shapes

- Minimal post-processing

- Ideal for high-quality components

Limitations of Lost Wax Casting:

- More likely to be contaminated

- Potential for cold shuts

- Pores from turbulence

This method is widely used in the aerospace, automotive, and jewelry industries. Engineers choose investment casting when they need delicate parts without requiring excessive additional processing. However, this method also has some drawbacks. Sometimes, residual ceramic shells or wax can cause contamination. Slag and oxidation can also affect the quality of the final part. Porosity or cold shuts can form if the metal has poor fluidity.

Note: Investment casting is ideal for small and complex parts, but operators must closely monitor the casting process to prevent defects.

Lost Foam Casting Pros and Cons

Lost foam casting is simple to operate and requires minimal manual labor. Many factories prefer this process because it saves time and costs. The table below lists its main advantages and limitations:

Advantages of Lost Foam Casting:

- Simplified process

- Reduced labor intensity

- Grande précision dimensionnelle

- Flexibilité de la conception

- Good casting quality

- Efficient riser placement

- Ease of process mastery

- Low investment with fast results

Disadvantages of Lost Foam Casting:

- Unsuitable for all metals

- Potentially higher emissions (organic fumes)

Lost foam casting allows workers to create parts of various shapes and high quality. It is easy to learn. This method is best suited for aluminum and cast iron. However, it is not suitable for all metals. It may also produce more fumes, so the plant needs good ventilation.

Tip: When choosing a process, engineers should consider its advantages and limitations. The best choice depends on the size, shape, and material of the part.

Choosing the Lost Wax and Lost Foam Casting Right Method

Key Selection Factors

Choosing between lost-wax casting and lost foam casting is crucial. Engineers will consider the mold material and the mold-making process. The type of part required is also important. The table below lists the differences between these factors:

| Facteur | Cire perdue | Moulage en mousse perdue |

|---|---|---|

| Matériau du motif | Cire | Foam (Polystyrene) |

| Process Similarity | Similar to investment casting | Similar to investment casting |

| Mold Creation | Requires a wax pattern to be melted out | Foam pattern is consumed during casting |

| Application | Precision parts, intricate designs | Larger parts, less intricate designs |

Project requirements are also critical. Lost foam casting is suitable for large, complex-shaped parts, as well as medium to large parts. This method reduces the cutting and assembly work. Lost-wax casting is better suited for small, highly detailed parts, especially those requiring extremely high precision.

Engineers will consider the manufacturing difficulty of the parts, as well as the number of parts and materials required. KEMING helps clients make choices by providing intelligent advice and utilizing new technologies. Their team uses 3D scanning technology to inspect foam models and metal molds, ensuring that each part is manufactured to the perfect fit.

Cas d'utilisation dans l'industrie

Different industries have different needs. The table below lists the best application scenarios for each process:

| Méthode de coulée | Preferred Use Cases | Adéquation des matériaux | Accuracy and Surface Finish | Volume de production |

|---|---|---|---|---|

| Moulage en mousse perdue | Large, geometrically simple parts like engine blocks and pump housings | Aluminum, ductile iron for normal temperatures | ±0.5–1.0 mm tolerances, basic surface finish | Medium-to-high production |

| Cire perdue | Precision-critical applications like aerospace components and medical devices | Stainless steels, superalloys, titanium | ±0.1–0.3 mm tolerances, superior surface finish | Low-to-medium production |

Automotive and machinery companies use lost foam casting to manufacture engine blocks and pumps. Aerospace and medical companies use investment casting to manufacture parts with extremely high requirements for fit and surface finish. Commin can provide both processes. They help factory customers achieve optimal casting results.

Tip: Be sure to choose a process that matches the project size, shape, and material. The KEMING team can help you choose the best solution for your factory projects.

Investment casting is best suited for parts requiring high precision. Many companies use it to manufacture parts with complex shapes and smooth surfaces. The table below lists the reasons why engineers choose this method for challenging tasks:

| Métrique | Valeur |

|---|---|

| Finition de la surface | 0.9–1.0 Ra |

| Précision | Better than 0.1 mm |

| Volume de production | Modéré |

Investment casting is suitable for larger or simpler parts. It can help factories save time and costs. When choosing a casting process, consider the material, the number of parts required, the complexity of the parts, and the budget. KEMING provides assistance at every stage to ensure clients choose the right process. For any questions, please contact the KEMING team.

FAQ

What are the main differences between investment casting and foam casting?

Investment casting uses wax patterns and ceramic molds. Foam casting uses foam molds and sand molds. Investment casting produces smoother surfaces and higher levels of detail. Foam casting is better suited for larger or simpler parts.

Which casting method is better suited for complex shapes?

Investment casting is best suited for complex shapes. It produces fine molds and smooth surfaces. Many industries choose this method to cast parts with delicate features or thin walls.

Can the two methods use the same metals?

Investment casting is suitable for a variety of metals, including steel, bronze, and aluminum. Foam casting is generally best suited for aluminum and cast iron. Each method has its specific metal compatibility.

How do the costs of the two methods compare?

Foam casting is generally less expensive for small and medium-volume production. Investment casting has a higher initial cost but is more cost-effective for high-volume production.