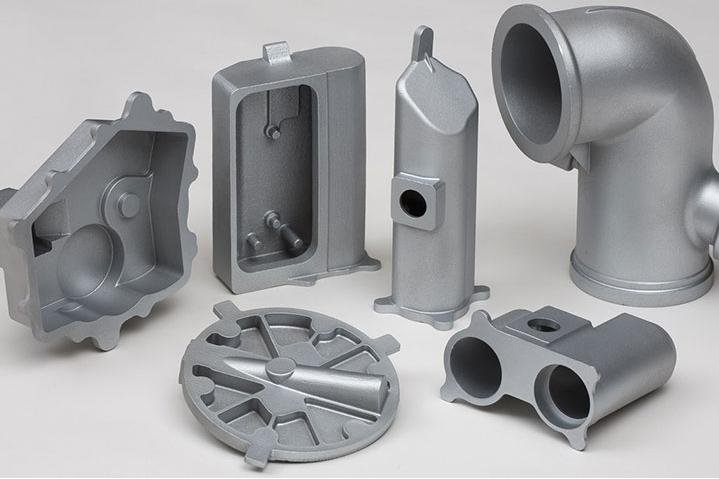

The cost of lost-wax casting ranges from $10 for small items to $500 or more for custom pieces. Prices vary depending on factors such as part size, design complexity, type of metal used, and the company you choose. KEMING collaborates with numerous industries to produce agricultural castings, automotive castings, railway castings, and more, and can provide a variety of lost-wax casting materials.

| Factor | Impact on Cost |

|---|---|

| Size | Larger parts require more material and processes, thus increasing costs. |

| Complexity | Intricate designs require more time and effort, thus increasing costs. |

| Material | Choosing metals such as titanium or stainless steel will alter the price and process. |

| Service Provider | The company’s tools and technical expertise significantly impact the total cost. |

Key Takeaways

- The cost of lost-wax casting ranges from $10 for small items to over $500 for special custom pieces. Prices vary depending on size, complexity, materials, and the number of workers.

- Choosing the right metal is crucial. Each metal has its own properties and price. For example, stainless steel is strong, durable, and inexpensive, while titanium is more expensive.

- The manufacturing process and steps also affect the price. More complex designs require skilled workers and take longer, leading to a higher total price.

- Mold costs also significantly impact costs. Reusable molds are best suited for large orders, while disposable molds are suitable for small or special projects.

- Providing clear project details helps the company provide an accurate quote. For best results, you should provide drawings, the type and quantity of metal required, and the desired surface finish.

Lost Wax Casting Cost Factors

Lost Wax Casting Material Choices

The materials you choose are a significant part of the cost. Different metals have different prices and uses. Some common metals include:

- Stainless Steel

- Carbon Steel

- Alloy Steel

- Brass

- Aluminum

- Duplex Stainless Steel

- Cast Iron

Each metal has its own advantages. Stainless steel and alloy steel are strong, durable, and rust-resistant, often used in machinery and medical devices. Aluminum is lightweight and inexpensive, so it is often used in automobiles and electronics. Brass and copper alloys are rust-resistant but more expensive. High-strength alloys may require special processing, thus increasing costs. KEMING offers over 100 metals to help you choose the right material. In jewelry making, the metal you choose affects the appearance and price of your jewelry.

The metal you use affects the price. Aluminum alloys, such as A380 and A413, are lightweight and easy to use, suitable for automotive and electronics. Copper and zinc alloys are more expensive but less prone to rust. High-strength alloys require additional machining, thus increasing costs. Lost-wax casting is a highly precise process, but the use of special metals and tools makes it more expensive than other processes.

Lost Wax Casting Labor and Production

The workers and steps involved in the part-making process also affect the price. The process involves multiple steps, such as wax injection, mold making, metal pouring, and cooling. Each step requires skilled workers and meticulous operation. Small parts may cost as little as $10 each. Wax injection costs approximately $1.50 each. Machining prices depend on the complexity of the design and the number of parts required.

Modern factories like KEMING use machines to increase production speed and reduce errors. The use of machines means less manual labor, thus lower prices. Rapid production is crucial for automotive and aircraft parts. Lost-wax casting also reduces post-production work, saving time and costs. In the jewelry industry, intricate designs require more work, thus increasing costs.

Lost Wax Casting Mold Fees

Mold costs are another significant component of costs. In investment casting, a new mold is needed for each part, increasing costs. For large orders, molds can be reused to reduce the cost per part. Reusable molds, while initially more expensive, gradually decrease in cost with frequent use. Disposable molds are more suitable for small-batch orders or custom jewelry due to their lower initial cost.

If you need to produce a large number of parts, reusable molds, while more expensive, are worth the price. Disposable molds are more suitable for small-batch orders or special parts. KEMING can help you choose the right mold based on your needs and budget. Manufacturing molds for precision parts can cost anywhere from $5,000 to $50,000, especially for parts requiring high precision.

Lost Wax Casting Finishing Options

Surface treatment affects the appearance and cost of parts. Surface treatments include polishing, painting, cutting, or coating. Complex designs require more surface treatment, which increases labor and material costs, and also means longer processing time.

KEMING offers a variety of surface treatments for parts, such as rust-resistant coatings or aesthetically pleasing paints. In the jewelry industry, surface treatment is crucial for both appearance and strength. More surface treatment means higher costs, but also a higher quality product. Consider the required level of surface treatment when budgeting.

Tip: Choosing the right metal and surface treatment process can help you achieve high-quality products and save costs in lost-wax casting.

Lost Wax Casting Price Examples

Lost Wax Casting Small Castings

Small castings, such as jewelry pendants or miniature artworks, start at around $10 each. Prices will vary depending on several factors. More complex designs are more expensive because they require more time and skill. Simpler shapes are less expensive. The metal you choose is also important. Stainless steel and aluminum are commonly used metals, but rarer metals like titanium are more expensive. Jewelry made of steel or aluminum is generally less expensive than gold or platinum jewelry. For example, a standard steel ring might cost between $10 and $20. A fine stainless steel pendant, however, could cost $50 or more. Small steel items are generally cheaper per pound than rare metals.

Lost Wax Casting Medium Projects

Medium-sized projects include custom art sculptures, mechanical parts, or tools. The unit price for these castings typically ranges from $100 to $500. The unit price decreases with larger orders because mold and setup costs can be spread across multiple products. Therefore, the price per kilogram of castings is lower when purchasing in bulk. A set of steel gears for a machine might cost $200 per set for a small order. With larger orders, the unit price can drop to $120 per set. Medium-sized projects require more steel, and complex designs also drive up the price.

Note: The unit price decreases with larger orders because the factory can produce faster.

Lost Wax Casting Large Orders

Large orders are for projects such as manufacturing or construction. These products require hundreds or thousands of steel or iron castings. For large orders, the price per ton of castings is crucial. Large orders may cost thousands of dollars, but the price per individual product can be significantly lower.

| Order Size | Typical Price Range | Notes |

|---|---|---|

| 100 units | $5,000 – $15,000 | Lower casting price per kg |

| 1,000 units | $30,000 – $100,000+ | Best casting price per ton |

Lost-wax casting takes longer than sand casting and is therefore more expensive. Some companies pay over $10,000 for a set of steel wheels manufactured using this process. Bulk orders for jewelry, such as steel bracelets or rings, can be cheaper due to the large quantity purchased at once.

Lost Wax Casting Additional Fees

Lost Wax Casting Minimum Orders

Many foundry companies have minimum order quantities. These requirements help them cover setup and parts manufacturing costs. Some companies prefer large orders, while others allow small orders. The table below lists the requirements of some companies:

| Provider | Minimum Order Quantity |

|---|---|

| Best Prototypes | 100 runs |

| Santa Fe Jewelers Supply | 10 pieces (for smaller pieces under 1” diameter) |

KEMING accepts orders of all sizes. This is convenient for customers who need only a small number of steel or iron jewelry parts, as well as customers who need a large number of steel castings for machinery.

Lost Wax Casting Shipping Costs

Your shipping and insurance methods will affect the price. Fast shipping is more expensive but allows you to receive your parts quickly. Insurance protects valuable items during transit. If your items are high-value, you may need higher insurance, which will increase the price. Long-distance shipping also increases costs. Good packaging boxes protect steel and iron castings from damage.

Tip: Always consult about shipping and insurance costs before placing an order. This will help you understand all costs.

Lost Wax Casting Custom Design Charges

Custom designs incur additional costs. Creating new designs for steel or iron requires time and expertise. Fine jewelry demands specialized craftsmanship. Molds and additional work increase casting costs. KEMING offers design, finishing, and parts inspection services to ensure every steel or jewelry casting perfectly meets your needs.

Note: Some companies, such as KEMING, include finishing and inspection as part of their services. This not only helps you save costs but also improves part quality.

Getting a Lost Wax Casting Quote

Project Details Needed

If you require a quote for lost-wax casting, please provide clear project details. Detailed information helps the company understand your needs and provide you with a reasonable price. Here is the key information you should provide:

- Drawings or sketches of the parts

- Metal type, such as steel or iron

- Quantity of parts required

- Dimensions and weight of each part

- Any special quality or tolerance requirements

- Desired surface finish

Drawings help demonstrate the final appearance of the parts. Choosing the appropriate metal and informing the company of your tolerance requirements helps them calculate costs. A more detailed description of your quality requirements will result in a better quote. Lost-wax casting can produce dimensionally precise parts. Therefore, providing accurate dimensional information is crucial. This is especially important for automotive and aircraft parts, as these parts must fit perfectly.

Tip: Providing more detailed information will help the company provide you with a quick and accurate quote.

Comparing Providers

Casting companies vary in quality. Before choosing a supplier, you should examine different companies. Here are some things to check:

- Precision and Quality – Check if they have ISO 9001 certification.

- Technology – Find out if they use CAD or 3D scanning technology.

- Material Selection – Ensure they can use a variety of metals for casting.

- Lead Time – Inquire about the production cycle for your order.

- Cost Structure – Check if the price is clear and reasonable.

- Customer Support – Assess how quickly they respond to inquiries.

- Reputation – Read reviews or case studies.

- Compliance – Ensure they adhere to industry standards.

A good casting company should have a robust factory and sufficient equipment to handle orders of all sizes. They should be able to complete work on time and process rush orders when needed. Need help? KEMING offers a one-stop service from design to finished product. Their team will answer your questions and help you choose the best option for your project.

Note: Choosing the right company can save you money and ensure high-quality castings every time.

Investment casting for small parts may cost as little as $10. Custom parts can cost as much as $500 or more. Many factors influence the price:

- Raw material costs

- Mold costs

- Part complexity and size

- Wax and slurry costs

- Labor and site costs

- Part production volume

KEMING helps clients choose the best casting method. Their team uses intelligent tools such as 3D scanning to help clients match the size, shape, and budget of their projects. Providing clear project details helps the company provide a reasonable quote for each order.