CNC turning parts are created by rotating a workpiece while a cutting tool precisely shapes it, ensuring high accuracy for a wide range of applications. CNC Turning is a vital process in modern manufacturing, delivering consistent and precise components every time. KEMING stands out as a trustworthy CNC Machining Manufacturer for both custom CNC turning and CNC milling machining, providing solutions tailored to your exact requirements. When you choose KEMING, you receive expertly crafted parts that meet your specifications with reliability and precision.

Key Takeaways

CNC turning gives very exact and accurate results. It is great for parts that need to fit very closely. This process helps cut down on waste and mistakes. It saves money and makes better parts when making many at once. CNC turning can make many different shapes. It works for simple round parts and also for special designs. You can pick from more than 50 materials. These include metals and plastics to fit what your project needs. KEMING can finish orders fast. They do this for both test pieces and big orders. You get your parts when you need them.

CNC turning features

Precision and accuracy

You want your parts to look just like your design. CNC turning helps you get this control. The machines follow computer instructions to move the cutting tool. This makes every part turn out the same. CNC turning can make parts with tight tolerances. It also gives repeatable results, even for big orders.

KEMING uses advanced machines for high precision. You can see this in the numbers below:

Tolerance Type | Precision Level |

|---|---|

Standard Production Tolerance | ±0.005 inches (0.13mm) |

Greater Accuracy Tolerance | ±0.002 inches (0.051mm) |

Reamed Holes Tolerance | ±0.0005 inches (0.0127mm) |

Feature Locations Tolerance | ±0.002 inches (0.051mm) |

CNC turning gives you steady quality. Manual machining can make good parts, but it is hard to keep every piece the same. CNC turning keeps the quality even, so you get fewer defects and less waste. This saves you money because fewer parts are thrown away.

Tip: If you need parts with very tight tolerances, CNC turning is a great choice. You get reliable results each time.

Surface finish and tolerances

You want your parts to look nice and work well. CNC turning makes smooth surfaces and sharp details. The machines move with care, so you get a clean finish with no rough spots. KEMING’s skilled workers can change the process to fit your needs. You can pick a shiny or matte surface.

You also get accurate tolerances. CNC turning lets you pick the exact size for your parts. You can ask for tight tolerances, even as close as ±0.001 inches. This control helps your parts fit together and work right.

CNC turning makes less scrap, so you save money.

The precision lowers the chance of defects during checks.

You get steady quality for big production runs.

Better accuracy means fewer rejected parts.

KEMING’s skill in precision machining helps your parts meet tough standards. You can trust their experience to make parts that match your needs every time.

Types of CNC turning parts

Cylindrical components

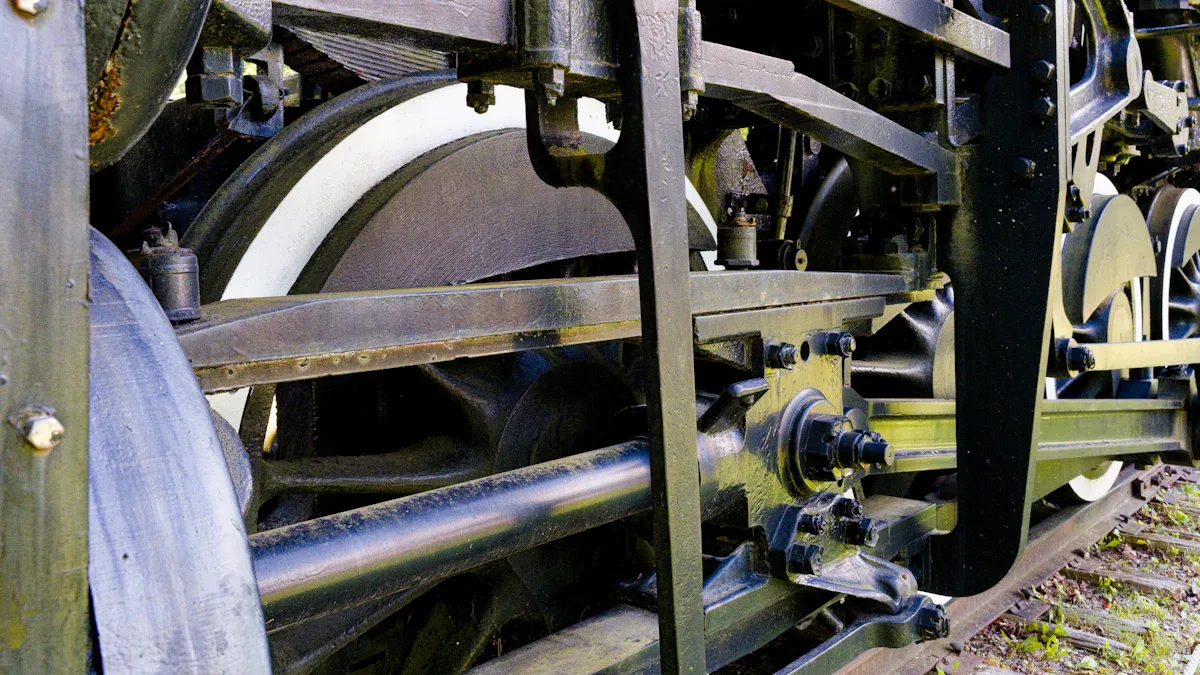

Machines and equipment use many round parts. CNC turning is great for making these shapes. The workpiece spins while the cutting tool shapes it. This makes the surface smooth and the size exact.

Here are some common cylindrical parts you might need:

Shafts: These move power or motion in engines.

Bushings: These help parts slide and lower friction.

Bearings: These hold spinning parts and keep them straight.

Pins and Dowels: These connect parts or help line them up.

Connectors and Couplings: These join different pieces together.

Axles: These hold wheels or gears in place.

Spacers and Hubs: These keep parts apart or in position.

KEMING can make these parts with high accuracy. You can order one piece or thousands. Their machines give you the same quality every time.

Tip: If you need round or tube-shaped parts, CNC turning is a smart choice. It works well for small and big orders.

Custom and complex shapes

Sometimes you need more than just round parts. CNC turning can make special shapes too. It works best for parts that are round or have symmetry. You can get cones, disks, or parts with grooves and threads.

The machine spins the material while the tool shapes it. This gives you smooth surfaces and exact sizes. If your part needs tapers or steps, CNC turning can do that.

KEMING’s team helps you make your ideas real. You can get one custom part or many for production. Their process is good for quick samples or big batches.

CNC turning materials

Metals used

You have many choices when you pick metals for your parts. KEMING offers over 50 types of metals, so you can find the best match for your project. Each metal has special qualities that help your part work better.

Here are five metals you might use:

Aluminum gives you lightweight parts. It resists rust and works well in many jobs.

Stainless steel offers strength and lasts a long time. It stands up to heat and keeps its shape.

Brass makes machining easy. It looks nice and resists corrosion.

Titanium gives you strong parts without adding much weight. It works well in tough jobs and is safe for medical use.

Copper helps with electrical and heat flow. It is easy to shape and resists damage from moisture.

You can choose a metal based on what your part needs to do. Some metals work better in high temperatures. Others resist chemicals or wear. KEMING helps you pick the right metal for your design.

Tip: If you need a part that must last a long time or handle stress, stainless steel or titanium may be the best choice.

A few main factors guide your decision. Look at this table to see what matters most:

Factor | Description |

|---|---|

Rigidity | Keeps your part stable and strong. |

Stability | Stops your part from bending or changing shape. |

Processing Performance | Shows how easy it is to machine the metal. |

Cost | Helps you balance quality and price. |

Plastics and composites

You can also use plastics and composites for CNC turning parts. KEMING gives you many options, so you can match the material to your needs. Plastics work well when you want light weight or special resistance.

Some popular choices include:

Polyvinyl Chloride (PVC) resists sun and water. You see it in medical and building parts.

Acrylic (PMMA) stays clear and does not break easily. It works for signs and displays.

Polyetheretherketone (PEEK) stands up to chemicals and heat. It fits tough jobs.

Polyacetal (POM) keeps its shape and is easy to machine. It works for gears and small parts.

Polyethylene (PE) resists chemicals. You find it in packaging and cars.

Polypropylene (PP) is light and resists chemicals. It works in food and auto parts.

Nylon 66 (Polyamide) is strong and slides easily. It fits gears and bearings.

Garolite G-10 is strong and resists rust. It works well in marine parts.

You should think about how your part will be used. Some plastics resist heat or chemicals. Others stay strong under stress. KEMING helps you choose the right plastic or composite for your project.

Note: If you need a part that must be light and resist chemicals, plastics like PEEK or PP are good options.

CNC turning applications

Automotive and aerospace

CNC turning is used in many fields. Car and airplane companies use it a lot. They need strong and exact parts. These parts must fit well and last long. You can find CNC turned parts in engines and gearboxes. They are also in control systems.

In 2024, cars use about 30–35% of all precision turned parts.

Airplane companies need parts that follow strict safety rules.

KEMING can make your parts quickly. You can order custom parts for cars or planes. You can also pick extra steps like anodizing or heat treating. These steps make your parts stronger and last longer.

Other fields use CNC turning too:

Oil and Gas

Agriculture

Alternative Energy

Medical Manufacturing Equipment

Aviation Components

Industrial Components

Defense

Construction

Tip: If you work in these areas, CNC turning gives you good parts you can trust.

Medical and electronics

Making medical and electronic parts needs special care. Medical parts often have tricky shapes. They use materials like titanium or special plastics. Electronics usually have simple shapes. They use common materials. Both need high precision. Medical parts must also meet health rules.

Aspect | Medical Device Manufacturing | Electronics Production |

|---|---|---|

Complexity of Shapes | Needs to handle tricky shapes and designs. | Usually simple shapes. |

Material Restrictions | Uses special materials like titanium and plastics. | Uses common materials. |

Production Speed | Slower because of checks and complex shapes. | Usually faster. |

Surface Finishes | Needs high precision and extra finishing. | Standard finish is fine. |

Regulatory Compliance | Must follow strict rules and standards. | Fewer rules to follow. |

Customization | More focus on custom devices. | Less focus on custom. |

Operator Skill | Needs skilled workers for hard jobs. | May need less skill. |

KEMING can make your medical parts fast, even if they are complex. You can pick extra steps like polishing or powder coating. These steps help your parts meet rules and look good.

Common extra steps are surface finishing, bead blasting, and anodizing. These steps make your parts last longer and look better. Your parts will work well and stay strong.

Benefits of CNC turning

Consistency and efficiency

You want every part to look like your plan. CNC turning helps you do this. The machines use computers to shape each part the same way. You get the same results, even with big orders. KEMING has ISO 9001 certification. This shows they care about quality. This means you get parts that meet tough rules every time.

Here is how CNC turning is different from old machining:

Evidence | Description |

|---|---|

Production Time | CNC machines work faster by using automation. |

Accuracy | CNC machines make every part very exact. |

Error Reduction | Less hand work means fewer mistakes and better results. |

Production Cycles | Computer control makes more parts faster. |

Precision and Repeatability | CNC machines give the same results every time. |

You save money because CNC turning makes less waste. The machines make fewer errors, so you throw away less. Automation also means people make fewer mistakes. Quality checks find problems early, so you do not waste stuff.

ISO 9001 means KEMING follows strict quality rules.

You get good parts with every order.

Less waste means you save money and help the planet.

Customization and flexibility

You might need parts for many jobs or special uses. CNC turning lets you make custom designs. You can ask for samples or big orders. KEMING can change the process for your needs, no matter the size.

Here are some ways CNC turning helps different fields:

Industry | Application Examples |

|---|---|

Aerospace manufacturing | Turbine shafts, landing gear pins, hydraulic fittings |

Automotive manufacturing | Crankshafts, brake rotors, engine parts |

Medical manufacturing | Implants, surgical tools |

Electronics manufacturing | Connectors, sensor housings, tiny shafts |

Robotics and automation | Joints, shafts, actuators |

Industrial machinery | Pump shafts, rollers, couplings |

You save money at every step. Digital tools and smart machines make things faster. You spend less on test runs and supplies. Fast samples help you try ideas and sell products sooner.

CNC turning lets you change designs quickly.

You can get custom parts for any field.

Fast work saves you time and money.

You get both samples and big orders with the same quality.

Tip: If you want custom parts fast and done right, CNC turning is a smart pick.

You can trust CNC turning to make parts that are very exact and useful. Here are some important things to know:

Precision means you can get small details and close fits.

Versatility lets you make many shapes and sizes.

Material compatibility means you can use metals or plastics.

Efficiency helps you get both samples and finished parts fast.

Industry | Example Parts |

|---|---|

Aerospace | Shafts, bushings, hydraulic fittings |

Automotive | Axles, drive shafts, camshafts |

Medical | Implants, surgical instruments |

Oil and Gas | Valves, pump parts |

Electronics | Terminals, connectors, housings |

You will notice new things like more automation and smarter ways to make things. KEMING gives you reliable custom CNC turning for any job. CNC turning parts are made by spinning material and using cutting tools. These parts are ready for many different industries.

FAQ

What is CNC turning?

CNC turning uses a computer-controlled machine to spin material and shape it with a cutting tool. You get parts that match your design with high accuracy. This process works well for making round or cylindrical parts.

Which materials can you use for CNC turning?

You can choose from metals like aluminum, stainless steel, brass, and titanium. You also have options for plastics such as PVC, PEEK, and nylon. KEMING offers over 50 material types for your project.

How fast can you get CNC turned parts?

KEMING provides rapid turnaround times. You can receive prototypes or production parts quickly. The exact speed depends on your order size and part complexity.

What industries use CNC turning parts?

You see CNC turning parts in automotive, aerospace, medical, electronics, oil and gas, and marine industries. These parts help machines work better and last longer.

Can you order custom CNC turning parts?

Yes, you can order custom parts for any project. KEMING helps you design and produce parts that fit your needs. You can request one piece or thousands.