- Rocker arms

- Shifter forks

- Brackets

- Housings

- Engine components

- Transmission parts

- Suspension parts

- Brake components

- Electric vehicle parts

Automotive investment casting enables the production of highly precise and intricate car parts such as engine blocks, gear housings, and battery housings. This advanced casting method is favored because it creates components that are both lightweight and exceptionally strong, capable of forming complex geometries. KEMING is a leader in automotive investment casting, offering rigorous quality control, a wide selection of materials, and specialized surface treatments tailored for all automotive casting parts used in modern vehicles.

Key Takeaways

- Investment casting makes car parts that are strong and light. These parts have exact shapes. This helps cars work better and keeps people safe.

- The process makes engine, transmission, suspension, brake, and electric vehicle parts. These parts are complex and have smooth surfaces. They also fit together very well.

- Metals like steel, aluminum, magnesium, and iron are used. Investment casting makes lighter parts. This helps cars use less fuel and make less pollution.

- Investment casting is more exact than sand and die casting. It gives better surfaces for small or medium groups of detailed parts.

- KEMING uses new technology and careful testing. This makes sure the parts are strong and last a long time. The parts work well for today’s cars.

Automotive Investment Casting Overview

What Is Investment Casting

Investment casting is also called the lost wax process. It makes metal parts that are very exact and smooth. First, a wax or 3D printed pattern is made to look like the part. Workers dip this pattern into a ceramic liquid to make a hard shell. When the shell dries, it gets heated to melt out the wax. This leaves a hollow space inside the shell. Hot metal is poured into the empty shell. The metal takes the shape of the pattern. When the metal cools, the shell is broken off. The finished part is now ready.

Automotive investment casting uses this way to make many car parts. These parts include engine pieces like cylinder heads and camshafts. It also makes transmission parts such as gear housings and shafts. Suspension parts like control arms and knuckles are made this way too. Many metals can be used, like aluminum, steel, and titanium. Special methods, like vacuum investment casting, help make better parts. QuickCast® patterns use 3D printing to make new designs faster. Heat treatments and coatings can make the parts stronger and last longer.

Why Use Investment Casting in Automotive

Car makers pick investment casting for many reasons. This process makes strong and tough parts with a tight structure. These parts work well in rough car conditions. Thin and light parts can be made without losing strength. Hard shapes can be made in one piece, so less assembly is needed. This lowers the chance of mistakes.

Automotive investment casting checks quality at every step. The process keeps parts the right size and shape, so they fit well and last long. Engineers can design tricky parts that are hard to make in other ways. The smooth finish helps the parts look and work better. Investment casting is good for making small or medium numbers of parts, so it saves money for many car jobs.

KEMING is a top company in automotive investment casting. They use modern machines and skilled workers to make great car parts. They work with many metals and coatings to meet the needs of today’s cars.

Common Automotive Casting Parts

Engine Components

Engine parts made by investment casting need to be strong and exact. This process makes engine blocks, cylinder heads, camshafts, rocker arms, and pistons. These parts have tricky shapes and must fit just right. Engine blocks and cylinder heads must work under high heat and stress. KEMING uses aluminum alloys and steel to make these parts. These materials make engine parts lighter and tougher. Lighter engine blocks and cylinder heads help cars use less fuel. Investment casting lets makers create detailed shapes that other ways cannot do. Machines and careful checks make sure each part is perfect. There is little extra work needed after casting, which saves time and money. Engine blocks and cylinder heads from this process are strong and last long. They also handle heat and stress well. KEMING’s skill in casting gives modern cars reliable engine blocks and cylinder heads.

- Engine blocks

- Cylinder heads

- Camshafts

- Rocker arms

- Pistons

Investment casting lets makers build engine blocks and cylinder heads with special shapes, light weight, and great strength. This helps today’s cars work better.

Transmission Parts

Transmission parts are important for how a car works. Investment casting makes transmission housings, gear housings, shifter forks, and shafts. These parts need to be very exact and often have hard shapes. The process gives smooth surfaces and tight fits, which are good for moving parts. KEMING uses steel, alloy steel, and aluminum for these parts. These metals make the parts strong and light. Putting many parts into one casting makes them stronger and easier to build.

| Transmission Parts | Advantages of Investment Casting |

|---|---|

| Transmission housings | Strong, durable, and lighter parts improve fuel efficiency |

| Gear housings | High precision, complex shapes, and minimal waste |

| Shifter forks | Combines multiple parts, improves manufacturing efficiency |

| Shafts | Tight tolerances and smooth finishes reduce or eliminate machining |

KEMING’s transmission parts are checked carefully to make sure they work well even in tough jobs.

Suspension and Steering Parts

Suspension and steering need parts that are strong and exact. Investment casting makes control arms, steering knuckles, hub carriers, racks, pinions, and brackets. These parts must hold heavy loads and move all the time. The process lets makers create detailed shapes and exact sizes. This helps cars handle better and stay safe. KEMING uses steel and aluminum to make these parts light and tough. Making tricky shapes in one piece means fewer mistakes and better parts.

- Control arms

- Steering knuckles

- Hub carriers

- Racks and pinions

- Brackets

Parts made this way help cars ride smoother and keep people safe.

Brake and Safety Components

Brake and safety parts are very important in cars. Investment casting makes brake calipers, ABS housings, and other safety parts. These must be strong and exact. KEMING uses cast aluminum and gray iron for these parts. Gray iron helps brakes last longer and stay cool. Careful checks, like X-ray and CT scans, make sure parts have no problems. Size checks and surface work make these parts even safer and stronger.

- Brake calipers

- ABS housings

- Brake discs

Investment casting helps make brake and safety parts that meet strict rules. This keeps drivers and passengers safe.

Fuel and Exhaust System Parts

Fuel and exhaust systems use many parts made by investment casting. These include turbocharger housings, catalytic converter bodies, fuel rail blocks, actuator rods, rocker arms, and exhaust gas regeneration parts. The process uses special metals that can take high heat and fight rust. KEMING makes sure each part meets the needs of new engines. Investment casting can make lots of these parts with the same good quality.

- Turbocharger housings

- Catalytic converter bodies

- Fuel rail blocks

- Actuator rods

- Rocker arms

These parts help cars use less fuel and make less pollution.

Electric Vehicle and New Energy Parts

Electric cars need special casting parts. Investment casting makes battery cases, motor housings, and big parts for electric cars. KEMING uses light aluminum alloys to make these parts strong and safe from rust. The process lets makers build big, single parts that are light and easy to put together. This helps car makers try new ideas and build cars faster.

- Battery cases

- Motor housings

- Structural components

Investment casting helps electric car makers build lighter, safer, and better cars with top-quality parts.

KEMING makes many kinds of casting parts from stainless steel, carbon steel, alloy steel, aluminum, and gray iron. Their smart casting ways and careful checks make sure every part works well in today’s cars.

Investment Casting Applications in Automotive

High-Precision Engine Parts

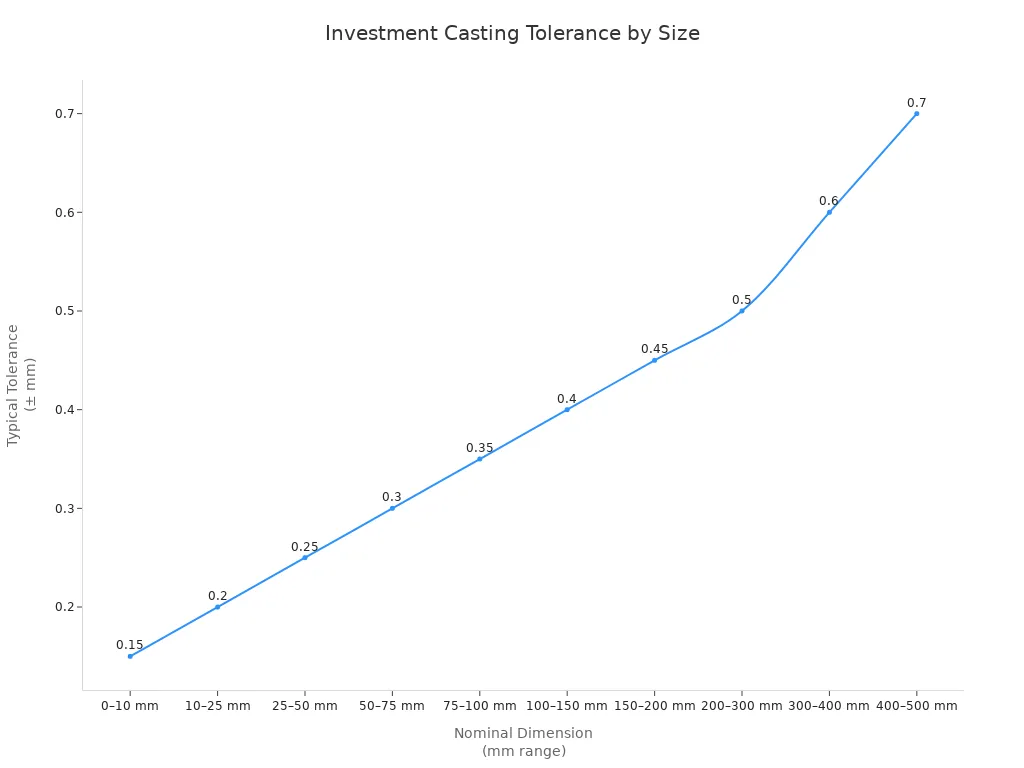

Car makers use investment casting to make engine parts. These parts need to be very exact and smooth. The process makes turbine blades, engine housings, gears, and valves. It helps create shapes that fit engines perfectly. Some engine parts need to be within ±0.15 mm for small ones. Bigger parts can be up to ±0.70 mm. The table below shows the usual tolerances for different sizes:

| Nominal Dimension (mm) | Typical Tolerance (± mm) |

|---|---|

| 0 – 10 | 0.15 |

| 10 – 25 | 0.20 |

| 25 – 50 | 0.25 |

| 50 – 75 | 0.30 |

| 75 – 100 | 0.35 |

| 100 – 150 | 0.40 |

| 150 – 200 | 0.45 |

| 200 – 300 | 0.50 |

| 300 – 400 | 0.60 |

| 400 – 500 | 0.70 |

These tight tolerances help engines work better and last longer.

Lightweight Structural Components

Investment casting helps car companies make lighter parts. These parts include turbocharger parts, exhaust manifolds, brackets, and suspension arms. The process uses metals like aluminum and magnesium. These metals make cars lighter. Thin walls and tricky shapes are possible with this method. Lighter cars use less fuel and meet tough emission rules. This process also cuts down on waste and saves money.

- Turbocharger parts

- Exhaust manifolds

- Brackets

- Suspension arms

These light parts help cars use less fuel and work better.

Safety-Critical Automotive Parts

Safety parts keep people safe in cars. Investment casting makes brake calipers, ABS housings, and other safety parts. These parts have no weak spots. The process follows strict rules like ASTM E433 and ASTM E192. Makers use tests like Magnetic Particle Inspection and radiographic testing. These tests find cracks or problems. Every part must pass these checks to be safe and strong.

Investment casting is used more and more in cars. Experts think the market will keep growing. It may grow by 4.9% to 6.0% each year for the next ten years. This is because car makers want lighter, stronger, and better parts. These parts help cars use less fuel and make less pollution.

Materials for Automotive Investment Casting

Steel Alloys

Steel alloys are very important in making car parts. These alloys make parts strong and tough. Car makers use steel for engine and transmission parts. Steel can handle a lot of stress and hard hits. Some steel alloys do not rust, so they last longer in wet places. Low alloy steels get harder and stronger after heat treatment. There are different types like carbon steel, alloy steel, and stainless steel. Each type is good for different car parts.

| Steel Alloy | Key Properties | Suitable Automotive Components |

|---|---|---|

| Carbon Steel | Cost-effective strength | General-purpose automotive parts |

| Alloy Steel | Enhanced strength, hardness, corrosion resistance | Parts needing improved mechanical properties |

| Stainless Steel | Excellent corrosion resistance, high strength, good thermal stability | Engine parts, transmission components, structural parts exposed to moisture and chemicals |

| 316L, 17-4 PH | Corrosion resistance, mechanical strength | Critical engine and transmission components |

Heat treatment, like quenching and tempering, makes steel parts even tougher for hard car jobs.

Aluminum and Magnesium Alloys

Aluminum and magnesium alloys are used to make car parts lighter. Aluminum die casting is used for engine blocks and battery housings. These metals help cars use less fuel and make less pollution. Magnesium is the lightest metal for car parts. It is about one third lighter than aluminum and much lighter than steel. Magnesium has a great strength-to-weight ratio. This is important for electric cars and new vehicles. Magnesium alloys also help cool engine and battery parts. Aluminum die casting lets makers create thin and tricky shapes. This helps design new car parts. Magnesium alloys like AZ91, AM60, and AM50 are used in seat frames and steering columns. Aluminum die casting is good for recycling and helps car makers protect the environment.

- Magnesium alloys: strong, light, and easy to shape

- Aluminum alloys: good for thin, complex parts

- Both metals: help cars save fuel and reduce pollution

Iron Castings

Iron castings, like gray iron and ductile iron, are tough and resist heat. These materials are good for parts that carry heavy loads and get hot. Investment casting makes detailed iron parts with smooth surfaces. Gray iron is used for engine blocks and manifolds. Ductile iron is used for steering knuckles and crankshafts. Malleable iron is good for bearing surfaces and drivetrain parts. Iron castings make car parts strong and last a long time.

| Type of Iron Casting | Key Mechanical Properties | Typical Automotive Applications |

|---|---|---|

| Gray Iron | Wear resistance, hardness | Engine blocks, cylinder heads, manifolds, enclosures |

| Ductile Iron | Fatigue resistance, yield strength | Steering knuckles, crankshafts, suspension parts |

| Malleable Iron | Lubricant retention, machinability | Bearing surfaces, drivetrain components, axle parts |

Investment casting lets car makers use iron to make strong and exact parts that last many years.

Advantages of Investment Casting for Automotive

Complex Geometries

Investment casting lets engineers make car parts with special shapes. Other ways cannot make these shapes. The process uses a wax pattern and a ceramic shell. This helps show every small detail. Thin walls and sharp corners are easy to make. Fine features are possible too. 3D printing helps try new ideas fast. Many car parts need these tricky shapes to work well. These parts include turbine blades, intake manifolds, and turbocharger housings.

| Automotive Part Category | Examples of Parts Produced | Key Features Enabled by Investment Casting |

|---|---|---|

| Engine Components | Turbine blades, manifolds, cylinder heads | High precision for better performance |

| Transmission Parts | Gears, shafts | Smooth surfaces and exact tooth profiles |

| Suspension Components | Control arms, knuckles | Strong, detailed shapes for stability |

| Brake Components | Brake calipers, brackets | Tight tolerances for safety |

| Exhaust System Parts | Turbocharger housings | Heat resistance and precise construction |

Investment casting helps make car parts with shapes that boost how well they work and keep people safe.

Strength and Durability

Car parts made by investment casting are strong and last long. The process works with many metals like alloy steels and aluminum alloys. These metals help parts handle heat, stress, and wear. Car makers use investment casting for engine, transmission, and suspension parts. These parts must last in hard jobs. The process also makes strong, one-piece parts. This means fewer weak spots.

- Parts can take heavy loads and stress.

- One-piece parts are stronger.

- Many metals can be used for different jobs.

Surface Finish and Quality

Investment casting gives car parts a smooth surface and the right size. The process copies the smooth wax pattern onto the metal part. Makers use fine ceramic coatings to control the finish. Most parts have a finish of about 125 microinches. This is smoother than sand casting. A smooth finish means less extra work after casting. It also helps parts fit together and look nice. The high quality of investment casting saves time and money for car makers.

A smooth surface and tight fit help car parts work better and last longer.

Investment Casting vs. Other Automotive Casting Methods

Sand Casting Comparison

Investment casting and sand casting both make car parts, but they are good for different things. Investment casting makes parts that are very exact and smooth. It can make shapes that are hard to do with other ways. Sand casting is better for big parts and making lots of them. Sand casting costs less and is faster, but the parts are rough and need more work after.

| Aspect | Investment Casting | Sand Casting |

|---|---|---|

| Cost | Higher, less post-processing | Lower, more post-processing |

| Precision | High, tight tolerances | Lower, rougher finish |

| Production Volume | Small to medium batches | High-volume, large parts |

| Part Size | Up to 200 lbs | Larger and heavier parts |

| Lead Time | Longer | Shorter |

Investment casting is best for small, tricky parts. Sand casting is better for big, simple parts.

Die Casting Comparison

High-pressure die casting is fast and makes many car parts quickly. This way uses metal molds and pushes hot metal in with high pressure. It works best with metals like aluminum, zinc, and magnesium. High-pressure die casting gives smooth and strong parts, but it cannot make tiny details like investment casting.

Investment casting uses wax patterns and ceramic molds. It can use many kinds of metals. This way makes parts with thin walls and hard shapes. High-pressure die casting is good for making lots of parts at once. Investment casting is better for small batches and parts that need to be very exact.

| Aspect | Investment Casting | High-Pressure Die Casting |

|---|---|---|

| Mold Type | Disposable wax pattern | Reusable metal dies |

| Production Volume | Low to medium | High |

| Material Compatibility | Ferrous and non-ferrous | Non-ferrous (aluminum, zinc, magnesium) |

| Precision & Tolerances | Exceptional | Good, but less precise |

| Surface Finish | Superior | Good |

| Complexity of Parts | Very high | Moderate |

When to Choose Investment Casting

Engineers pick investment casting when they need parts with hard shapes and smooth surfaces. This way is good for parts up to 200 pounds and under 8 inches. It is best for parts that must be strong but light or use special metals. Investment casting also helps when you want to do less extra work after making the part.

High-pressure die casting is best for making lots of simple, non-ferrous parts fast. It is good when you care about speed and cost. But investment casting is better for tricky shapes, many metal choices, and parts that must be perfect.

Tip: Pick investment casting for small, detailed parts. Pick high-pressure die casting for lots of simple, non-ferrous parts.

Investment casting makes many key car parts like engine, transmission, and brake components. These parts help cars get lighter, safer, and work better. New materials and digital tools are making casting improve more. KEMING uses careful checks and new technology to give strong parts. As electric vehicles become more common, investment casting will be even more important for making cars in the future.

FAQ

What automotive parts benefit most from investment casting?

Engine components, transmission housings, suspension arms, brake calipers, and electric vehicle parts get the most help from investment casting. This process makes these parts very exact and with tricky shapes. It helps make parts stronger, lighter, and more dependable in today’s cars.

Why do car makers choose investment casting over other methods?

Car makers like investment casting because it makes detailed, light, and strong parts. The process gives tight fits and smooth surfaces. It works with many metals, so it is good for important car parts.

What materials does KEMING use for automotive castings?

KEMING uses carbon steel, alloy steel, stainless steel, aluminum, magnesium, gray iron, and ductile iron. Each metal has its own good points for strength, fighting rust, or making parts lighter. KEMING picks the right metal for each car part’s needs.

How does KEMING ensure quality in automotive castings?

KEMING checks every part with special tools like CMM and laser scanners. The team does tests that do not harm the part and checks how strong it is. Every part must pass strict checks to meet world rules and keep people safe.

Can investment casting support electric vehicle (EV) parts?

Yes. Investment casting makes battery cases, motor housings, and light parts for EVs. The process can make tricky shapes and use metals that help cut weight. This helps electric cars work better and use less energy.