Sand Casting and Permanent Mold Casting What Sets Them Apart

Sand casting does not use a mold that lasts forever. In sand casting, workers make a new sand mold for each part. Permanent mold casting uses a metal mold that

Sand casting does not use a mold that lasts forever. In sand casting, workers make a new sand mold for each part. Permanent mold casting uses a metal mold that

You can make a sand casting mould by shaping special sand around a pattern, then removing the pattern to form a cavity. This process lets you create strong metal shapes

You can get better results in investment casting by using some easy rules. Pick smooth changes and make your designs simple. Do not add extra things that make the process

You can find many kinds of wax used in investment casting. These include filled pattern wax, non-filled pattern wax, runner wax, sticky wax, water-soluble wax, paraffin, beeswax, jeweler’s wax, microcrystalline,

You cannot use most investment casting molds again. The process uses ceramic molds that are thrown away after casting. These molds break off the metal part when finished. Using each

Investment casting utilizes a variety of materials to create precise and durable parts. Common materials include aluminum alloys, stainless steel, carbon steel, alloy steel, copper alloys, nickel-based and cobalt-based superalloys,

Investment casting and die casting are used for different applications. Investment casting is ideal for creating complex shapes and can be used with a wide variety of materials. Die casting,

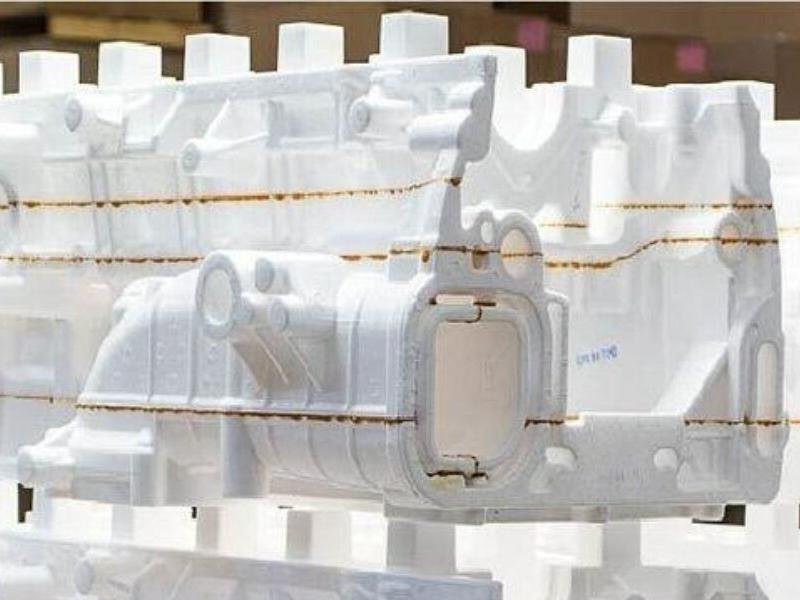

Ductile Iron Lost Foam Casting is a foundry process that involves creating foam patterns that are packed into sand and surrounded by molten metal, which vaporizes and replaces the foam

Alloy Steel Lost Wax Casting is a manufacturing process used to make complex and intricate shapes and structures from alloy steel. It is a precision casting method that uses wax

Capability

Leave Your Message