Investment casting molds are crucial for manufacturing high-precision parts. Industries such as aerospace and automotive have extremely high precision requirements for parts. Precision casting can produce complex-shaped parts with very low error. The precision casting process utilizes new technologies such as robotics and 3D printing to ensure perfect consistency in the precision and detail of each part. KEMING is a trusted company with strict quality control and provides customized solutions for various industries. Their hard work helps manufacturers achieve the highest standards every time.

Key Takeaways

- Precision casting molds can produce parts with extremely high precision, with errors as small as ±0.1mm. This is crucial for products such as aircraft and medical devices.

- Material waste in precision casting is minimal, only 5-10%, compared to up to 60% in traditional processes. This helps save time and costs.

- KEMING uses new technologies such as 3D printing and machinery to make the casting process more precise and efficient.

- Choosing the right mold material is crucial. It changes the strength and smoothness of the part, making it suitable for a wide variety of applications.

- KEMING consistently adheres to strict quality control and industry standards to ensure the safety and reliability of parts, meeting customer needs.

Precision with Investment Casting Molds

Investment Casting Process Overview

Precision investment casting is the preferred method for manufacturing high-precision parts. This process involves multiple steps, each rigorously monitored. Each step is crucial, ensuring part accuracy and consistency in every casting. KEMING employs new technologies and stringent inspection processes to ensure superior quality in every casting.

Precision investment casting enables companies to produce parts with rich detail and minimal error. This means fewer additional steps, saving time and costs.

The following are the main steps of the precision investment casting process:

| Step Number | Step Name | Description |

|---|---|---|

| 1 | Mold Making | Making specialized molds helps in manufacturing high-precision products. |

| 2 | Wax Injection | Wax is injected into the mold to create a model identical in size to the final part. |

| 3 | Shell Coating | The wax model is repeatedly immersed in a ceramic coating to form a hard outer shell. |

| 4 | Dewax | TThe outer shell is heated to melt and dewax the wax, preparing the mold for metal casting. |

| 5 | Casting or Pouring | Hot molten metal is poured into the mold; this is a crucial step. |

| 6 | Shell Removing | The hard outer shell is removed to expose the new part, and excess metal is removed. |

| 7 | Heat Treatment | The new part undergoes various heat treatments to enhance its strength. |

| 8 | Surface Finishing | The part is cleaned using sandblasting to achieve a smoother surface. |

| 9 | Anti-rust Treatment | Oil or paint is applied to the part to prevent rust. |

| 10 | Quality Inspection | All parts undergo careful inspection before leaving the factory to ensure quality. |

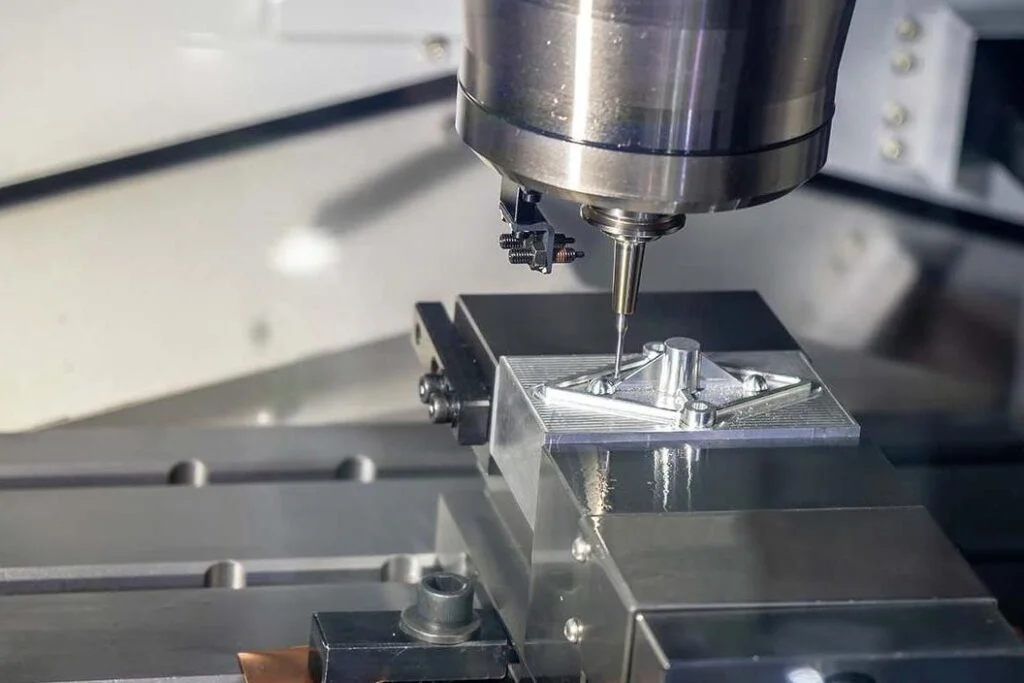

KEMING’s expertise in precision casting molds means meticulous attention to detail at every step. Their employees utilize CNC machine tools and modern facilities to ensure consistency in every part for all applications.

Mold Design and Accuracy

Mold design is fundamental to precision casting parts. The way the mold is made determines the shape, smoothness, and dimensional accuracy of the final part. Comming’s engineers employ ingenious methods to create molds that meet stringent dimensional and shape requirements.

- High-quality wax models help ensure the dimensional accuracy of the final part.

- Premium ceramic shells ensure consistent dimensions for each part.

- Controlling the metal pouring process improves the quality of the finished part.

Precision casting molds allow companies to produce parts with tolerances as small as ±0.1 mm. This is crucial for products such as aircraft and medical devices, as even minute errors can cause serious problems. This process also means less additional work is required, saving time and money.

| Tolerance Range | Measurement Units |

|---|---|

| ±0.002 to ±0.010 inches | ±0.05 to ±0.25 mm |

| Most standard features | ±0.003-0.005 inches/±0.08-0.13 mm |

KEMING Precision Casting Molds helps customers control these minute errors and manufacture complex-shaped parts. Their extensive experience in various casting methods, such as investment casting and shell casting, enables them to meet customers’ specific needs.

Material Selection Impact

Choosing the right mold material affects the smoothness and strength of the casting.

- Smooth ceramic molds allow for clean surfaces, sometimes with a roughness of 125 RMS or even higher.

- This means fewer subsequent machining steps are required for the part.

- Ceramics also facilitate the manufacture of complex metal parts with high precision and smooth surfaces.

Investment casting allows companies to choose from a wide range of metal materials. Komin can process a variety of metals, such as stainless steel, carbon steel, nickel-based alloys, copper-based alloys, aluminum, and titanium. Each metal is suitable for different applications:

| Metal Type | Common Alloys | Applications |

|---|---|---|

| Stainless Steel Alloys | 304, 316, 17-4PH | Medical devices, automotive parts, and electronics |

| Carbon steel and low-alloy steel | AISI 4140, AISI 8620 | High-strength parts, tools, and heavy-duty supports |

| Nickel-Based Alloys | Inconel 625, 718 | Aircraft, gas turbines, and high-pressure systems |

| Copper-Based Alloys | Bronze, Brass | Plumbing, decorations, and boat parts |

| Aluminum Alloys | A356, 319 | Electric cars and other products |

| Titanium Alloys | Ti-6Al-4V | Aircraft and Medical Applications |

KEMING Precision Casting Molds and Refined Processes help customers achieve optimal results. They deeply understand customer needs. With a profound understanding of materials and casting processes, they ensure that every part is precise, dimensionally correct, and performs exceptionally well.

Choosing KEMING means having a partner who understands the importance of precision. Their commitment to innovation and continuous quality improvement makes them a leader in the precision casting industry.

Quality and Integrity Guaranteed

Process Control and Inspection

KEMING employs rigorous process control and inspection to ensure that every casting meets standards. Their team uses specialized tools to inspect each step. These inspections help identify problems early, thus guaranteeing the strength and safety of each part. X-ray inspection is crucial in precision casting. It can detect internal cracks and pores in metal that are invisible to the naked eye. X-ray inspection records all problems. This process ensures the safety and strength of the casting.

| Test Method | Purpose | Standards Applied |

|---|---|---|

| Hardness Testing | Make sure the metal is strong enough | N/A |

| Magnetic Particle Inspection (MPI) | Find cracks on or near the surface | N/A |

| Material Composition Testing | Check what the metal is made of | N/A |

| X-Ray Testing | Look for hidden problems inside | N/A |

| Dimensional Inspection | Check if the size is correct | ASTM, DIN, JIS |

| Surface Roughness | See how smooth the part is | Ra 1.6-6.3 μm typical |

| Mechanical Properties | Make sure the part is strong | Material specifications |

| Visual Inspection | Look for problems on the surface | Industry standards |

Meeting Industry Standards

KEMING adheres to stringent global industry standards. These standards help them produce safe and high-quality parts. The company complies with ISO 9001:2008 quality management system standards and IATF 16949 automotive manufacturing standards. They also use ASTM and DIN standards to specify dimensions and materials. These specifications ensure that every casting meets the requirements of products such as aircraft and automobiles.

| Standard | Description |

|---|---|

| ASTM B83 | Specifies the specifications for high-quality investment casting. |

| AMS 4610 | Specifies the materials that should be used in castings. |

| ISO 8062 | Specifies the requirements for dimensional accuracy. |

- There are strict regulations regarding the metals used in casting.

- There are also corresponding regulations regarding the wax used to make models.

Consistency and Reliability

Precision casting molds help KEMING produce consistently high-quality parts every time. Its rigorous rules and inspection processes ensure dimensional accuracy. Each part fits perfectly to the design. The company is committed to ensuring that every casting achieves optimal performance. KEMING’s unwavering pursuit of quality and integrity sets it apart in the manufacturing industry.

KEMING’s precision casting molds and inspection processes give customers peace of mind. Every product meets stringent strength and reliability standards.

Benefits of the Investment Casting Process

Reduced Machining and Waste

Manufacturers favor precision casting because it saves costs and time. Parts produced by this process are nearly perfectly shaped from the start. This means workers don’t need to remove excessive material. Parts fit well, so companies don’t spend a lot of time on repairs. Thin parts produced using this process require only minimal finishing. There is also less scrap compared to traditional casting methods.

- Precision casting produces well-fitting parts, thus requiring less repair work.

- This process enables the creation of complex shapes and smooth parts, saving time and costs.

- Material waste is only 5-10%, compared to up to 60% in traditional casting processes.

| Casting Method | Material Waste (%) |

|---|---|

| Traditional Casting | Up to 60% |

| Investment Casting | 5-10% |

Complex Shapes and Flexibility

Investment casting molds enable companies to create shapes that are difficult to achieve with other processes. This process allows workers to create detailed designs and tailor them to each project. Companies can choose different materials based on varying needs, such as strength or lifespan. The thickness, weight, and density of parts are all flexibly controllable. Molds are inexpensive, and parts have a smooth, high-performance finish.

| Feature | Description |

|---|---|

| High Precision | Investment casting can produce highly precise and complex shapes. |

| Material Options | A wide variety of materials are available, allowing for flexible design variations. |

| Production Volume | Suitable for producing large quantities of parts at once, with high speed. |

| Design Flexibility | Allows workers to create special shapes and patterns. |

| Sustainability | Materials can be reused, contributing to environmental protection. |

Investment casting is highly flexible, making it ideal for jobs requiring precise and robust parts.

Applications Across Industries

Investment casting is used across many industries due to its effectiveness. KEMING applies this process to the automotive, train, construction, mining, and shipbuilding industries. In train manufacturing, KEMING uses carbon steel and low-alloy steel to create robust parts of the correct dimensions. This process is also suitable for industries such as oil and gas, marine, electronics, energy, medical, and defense.

- Oil and Gas: Drill bits, nozzles, tool fittings, stabilizers.

- Marine: Propellers, pumps, engine parts.

- Electronics: Small metal parts, antenna mounts, sensors.

- Energy: Turbine blades, valve parts, pump housings.

- Medical: Surgical instruments, prostheses.

- Defense: Housings, brackets, firearm parts.

Manufacturers rely on investment casting because it ensures the production of high-quality parts every time. This process enables the creation of dimensionally precise and complex-shaped parts, which is crucial for new manufacturing methods. Investment casting has emerged as more industries seek ways to manufacture stronger and more precise parts.

Challenges and Innovations in Investment Casting

Common Defects and Solutions

Manufacturers encounter several problems during the investment casting process. These problems can lead to reduced part accuracy or reliability. Sometimes, it can even be difficult to achieve the required precise dimensions. The table below lists common defects, their causes, and how experts can prevent them:

| Defect Type | Causes | Prevention Strategies |

|---|---|---|

| Porosity | Air trapping, poor wax pattern uniformity | Improve by setting up venting channels, vacuum degassing, and controlling wax pattern quality. |

| Shrinkage Cavities | Insufficient metal pouring, poor gating design | Improve gating design, mold simulation, and control cooling. |

| Misruns | Pouring temperature too low, mold too narrow | Preheat molds, manage pouring speed and temperature |

| Surface Cracks | Thermal Stress, shell too thin | Slow cooling rate, shell material too flexible |

| Inclusions | Mold damage, metal contamination | Use high-quality shell, maintain a clean processing environment |

| Gas Holes | Excessive moisture in the mold, pouring speed too fast | Preheat shell, inert gas purging |

| Dimensional Inaccuracies | Wax pattern shrinkage, mold deformation | Automatic wax pattern injection, CNC machining |

Advances in Mold Technology

Innovative concepts have dramatically transformed the investment casting process. Today, manufacturers utilize 3D printing to create wax models or plastic prototypes, enabling the faster production of complex-shaped parts. Higher-quality ceramic materials result in stronger, more heat-resistant shells, helping to maintain precise dimensions and shapes. Robots and machines can perform shell construction and wax model removal in the same manner. IoT technology allows workers to monitor the entire process in real time, improving part accuracy and reducing errors.

| Advancement Type | Description |

|---|---|

| 3D Printing Models | Directly create models of complex geometries |

| Advanced ceramic materials | Enhanced thermal stability and strength |

| Automation and robotics | Achieve consistent shell construction and wax pattern removal |

| Reinforced metal alloys | Superior mechanical properties and temperature resistance |

| Process control and monitoring | Real-time data analysis ensures accuracy |

These new technologies help KEMING manufacture highly precise and versatile parts.

Future Trends in Precision Manufacturing

The future of investment casting is bright. Manufacturers are using higher-quality materials, such as new superalloys and special compounds. These materials make parts stronger and more durable. 3D printing technology helps to quickly create molds, saving time. Robotics and artificial intelligence technologies help optimize production processes and detect problems early. New cooling methods improve the internal conditions of metals. This is crucial for industries such as aircraft and others that require perfectly crafted parts. More and more companies need precision casting to produce green energy and electric vehicles. There is also a desire to increase recycling rates and reduce pollution.

Precision casting molds and rigorous process inspections help manufacturers obtain highly accurate and high-quality parts. Commin uses specialized tools to inspect parts and monitors the entire production process. This helps them produce reliable parts. The table below shows how these steps ensure high quality:

| Quality Factor | Description |

|---|---|

| Dimensional Accuracy | Parts are measured using specialized tools to ensure precision. |

| X-ray Inspection | Hidden problems are detected, ensuring product safety. |

| Final Inspection | The inner and outer surfaces of each part are inspected. |

KEMING is a trusted precision casting company. The precision casting industry is growing steadily year by year:

- Experts predict that the market will grow at an annual rate of 6% from 2024 to 2035.

- By 2030, the global precision casting market may reach $27.8 billion.

New technologies such as 3D printing and smart machines will transform the way products are manufactured. KEMING continuously explores new methods to strive for excellence.