Precision machined parts are made to fit exactly with other parts. Makers use special machines like CNC milling, turning, and grinding. These machines help them make parts that are very accurate. These parts are important in many industries like cars, medicine, and airplanes. In 2023, car makers needed precision machined parts for engines and transmissions. KEMING uses a special way that mixes metal investment casting with precision machining. This helps them make parts that are very high quality.

Key Takeaways About Precision Machined Components Overview

Precision machined parts are made to fit with other parts. This makes sure they are very accurate and high quality. These parts are used in cars, planes, and medical tools.

Tolerances in precision machining are very small. In medical devices, they can be as tiny as 1-3 microns. This helps stop breakdowns and makes products work better.

Surface finish changes how parts move and wear out. Smoother finishes lower friction and help parts last longer.

CNC machining and casting are important ways to make precision machined parts. These methods let us create complex shapes and smooth finishes.

Picking the right materials, like metals or plastics, is very important. It helps the parts last longer and work well.

Precision Machined Features

Tolerances in Precision Machining for Exact Dimensions

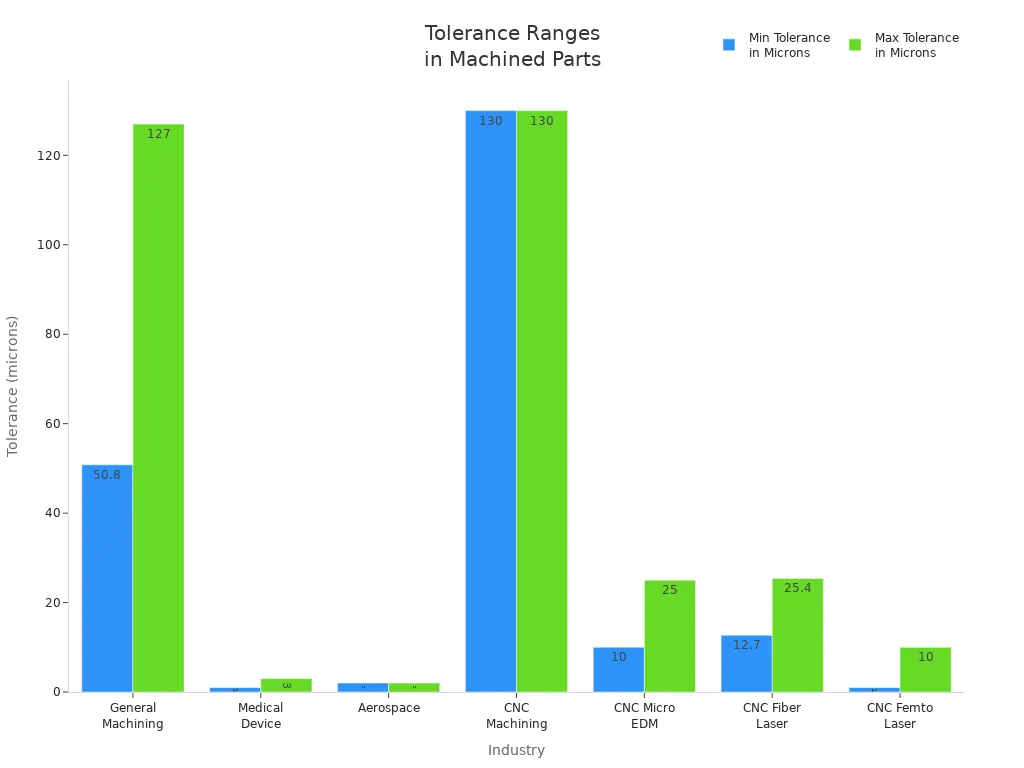

Tolerances show how much a part’s size can change. The part still works if it stays in these limits. Engineers set these limits for each part. This makes sure every piece fits and works right. In precision machined parts, tolerances are very small. Most CNC shops use a standard tolerance of +/- 0.005 inches (0.13 mm). Some industries need even smaller tolerances. Medical device makers want tolerances as tiny as 1-3 microns. Aerospace companies may need parts with tolerances of 2 microns or less.

Industry | Typical Tolerance Range |

|---|---|

General Machining | +/- 2-5 thousandths of an inch |

Medical Device Manufacturing | 1-3 microns |

Aerospace | 2 microns or less |

CNC Machining | +/- 0.005 inches (0.13 mm) |

CNC Micro Machining EDM | +/- 0.010mm to +/- 0.025mm |

CNC Fiber Laser Machining | +/- 0.0127mm to +/- 0.0254mm |

CNC Femto Laser Machining | +/- 0.001mm to +/- 0.010mm |

Small tolerances help parts fit together well. This lowers the chance of breakdowns. It also makes products better. Even tiny mistakes in tolerance can cause big problems. This is true for cars and airplanes. KEMING uses advanced machines to keep tolerances tight and steady.

Accuracy Levels Achieved in Precision Machined Parts

Accuracy means how close a part’s size and shape are to the design. Precision machined parts must match the design exactly. Workers use special tools to check accuracy. These tools include coordinate measuring machines, optical comparators, and precision gauges. Laser scanning and automated systems also help measure parts fast and correctly.

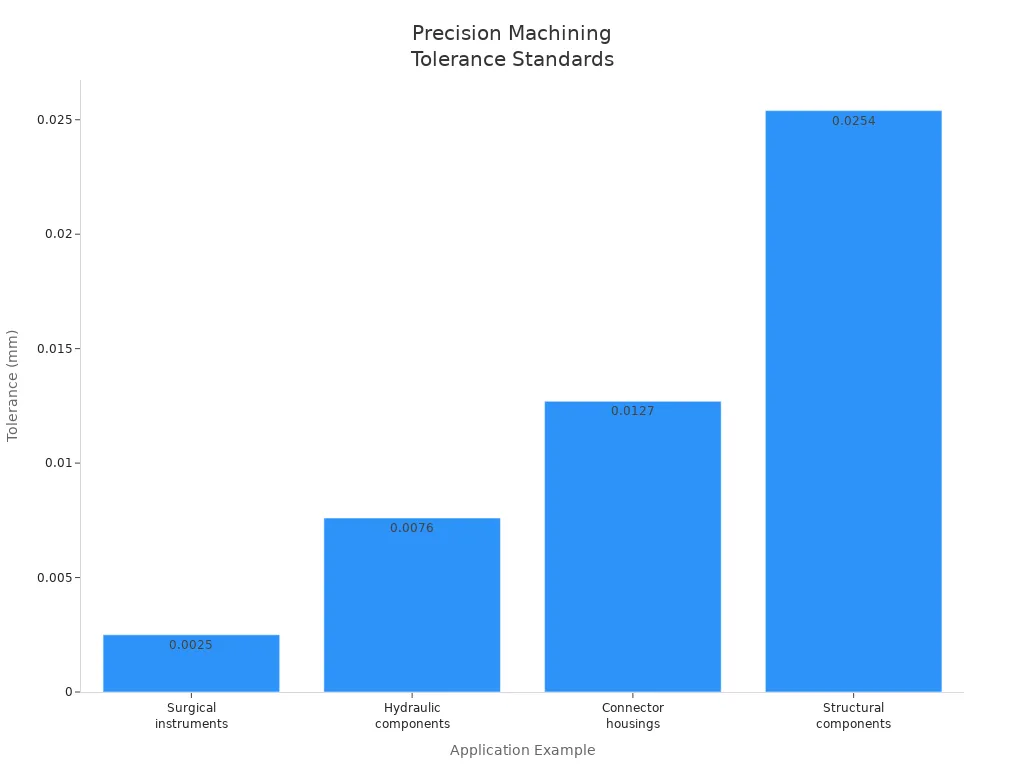

Tolerance Range | Application Examples | Typical Industries |

|---|---|---|

±0.0025 mm (±0.0001″) | Surgical instruments, precision bearings | Medical devices, aerospace |

±0.0076 mm (±0.0003″) | Hydraulic components, optical mounts | Defense, instrumentation |

±0.0127 mm (±0.0005″) | Connector housings, valve bodies | Automotive, electronics |

±0.0254 mm (±0.001″) | Structural components, housings | General precision manufacturing |

Quality checks happen all the time. First article inspection checks the first part made. In-process monitoring watches parts as they are made. Statistical process control helps find problems early. Certification standards like ISO 9001:2015 and AS9100D make sure parts follow strict rules. KEMING uses these methods to give customers precision machined parts that meet their needs.

Surface Finish Quality of Precision Machined Components

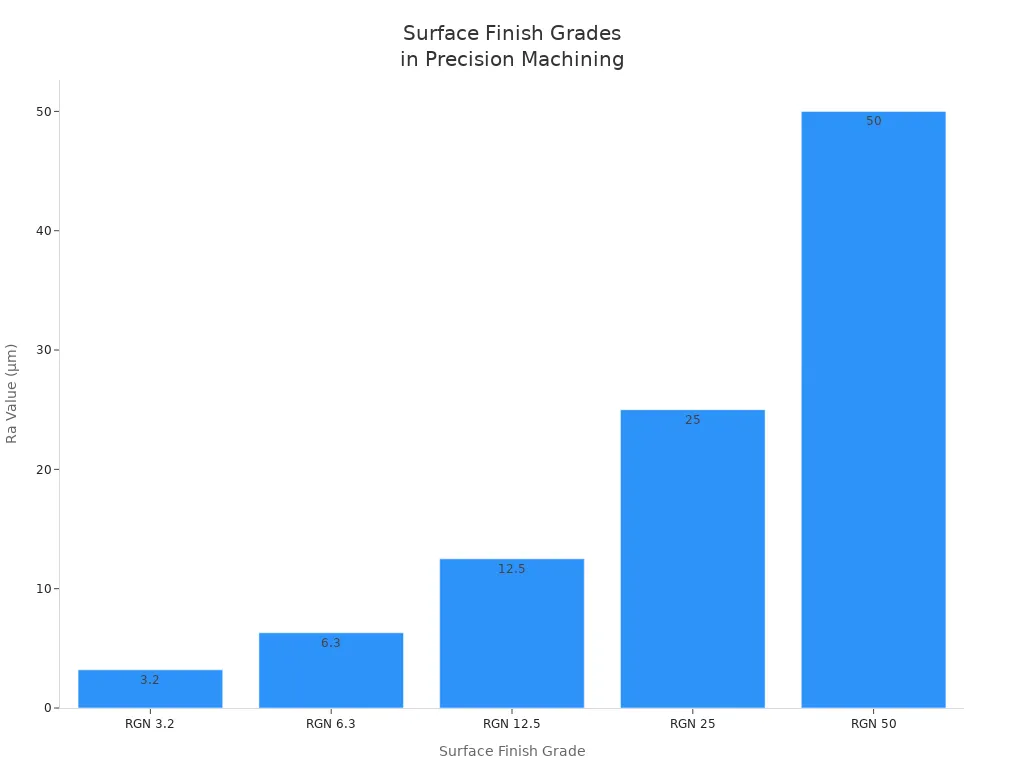

Surface finish tells how smooth or rough a part feels and looks. The finish affects how parts move, wear, and seal. Engineers measure surface finish using Ra values. Ra values show the average roughness in micrometers (µm). Smoother finishes help parts last longer and work better.

Surface Finish Grade | Ra Value (µm) | Characteristics | Uses |

|---|---|---|---|

RGN 3.2 | 3.2 | Moderately rough surface | Common in less critical parts like general hardware and construction components. |

RGN 6.3 | 6.3 | Rougher surface texture, visible to the naked eye | Suitable for less refined applications like certain industrial equipment and consumer products. |

RGN 12.5 | 12.5 | Clearly rough surface | Often found in components that require increased friction or grip. |

RGN 25 | 25 | Very rough surface | Used in applications where surface finish is not critical, such as in some castings and rough forgings. |

RGN 50 to RGN 800 | 50 to 800 | Progressively coarser surfaces | Cater to very rough and coarse applications, often in heavy machinery, agricultural equipment, and non-aesthetic components. |

Surface finish matters for many reasons:

Smoother surfaces lower friction and wear.

Good finishes help seals work better.

Shiny finishes look nice and can help electricity flow.

Rough surfaces help paint and glue stick.

In a ball bearing, a smooth surface finish lowers friction. This helps the bearing last longer. If the finish is poor, the bearing may wear out fast. This can happen even if its size is correct.

KEMING uses contact and non-contact ways to measure surface finish. Machine vision and ultrasonic sensors help check finishes during production. Their hybrid process mixes casting and CNC machining. This makes parts with great surface finishes and tight tolerances.

Manufacturing Processes Used for Precision Machined Parts

KEMING uses many advanced ways to make precision machined parts. Each way helps shape, improve, and finish parts. These parts are needed in industries that want high accuracy.

CNC Machining Process for High Precision Manufacturing

CNC machining means Computer Numerical Control machining. This way uses computers to control machines. The machines cut, shape, and finish metal or plastic parts. They follow exact plans from a digital design. This makes parts with tight tolerances and smooth surfaces.

Main steps in CNC machining:

Define: Engineers choose what the part does and how it looks.

Feasibility: They check if machines can make the part.

Develop: Designers and makers build digital models with CAD or CAM.

Validate: Each part gets checked to match the design.

Implement: The CNC machine makes the part.

Evaluate: Teams test the part and look for ways to make it better.

CNC machining has many good points:

It makes parts with high precision and tight tolerances.

Machines can work for a long time with little help.

The process lowers mistakes and waste by using less human work.

KEMING uses CNC milling, turning, drilling, and EDM to make complex shapes. Their shop has more than 50 CNC machines. This helps them fill both small and big orders.

Casting Techniques Combined with Precision Machining Processes

Casting shapes metal by pouring it into a mold. KEMING uses metal investment casting to make the main shape of a part. First, they make a wax pattern and cover it with ceramic. When the ceramic hardens, the wax melts away. This leaves a space for metal. Hot metal fills the space and cools to make the part.

Investment casting makes parts with lots of detail and accuracy. It works well for parts that need to be strong or fight rust. This way is great for making tough, high-quality parts.

Process | Tolerances Achievable |

|---|---|

CNC Machining | Up to +/- 0.0002” (0.005 mm) |

Casting | Generally looser tolerances |

CNC machining gives smoother surfaces than casting. Casting leaves rougher surfaces. KEMING uses CNC machining to make cast parts more accurate and smooth.

KEMING’s special way starts with investment casting and ends with CNC machining. This mixes the best parts of both ways. It makes precision machined parts with great detail and surface quality.

Grinding Operations for Enhanced Surface Quality and Fit

Grinding is a finishing way that makes parts more accurate and smooth. KEMING uses CNC grinding to meet strict rules for flatness, parallelism, and smoothness.

Common grinding methods include:

Surface Grinding: Makes flat surfaces smooth and exact.

Cylindrical Grinding: Shapes and finishes round surfaces.

Centerless Grinding: Refines small round parts without holding them.

Jig Grinding: Makes complex shapes with high accuracy.

Creep Feed Grinding: Works with tough materials and tricky designs.

Thread Grinding: Makes exact threads for screws and bolts.

Grinding helps parts fit together better and last longer. It can make shiny finishes for low friction and nice looks. Grinding also removes sharp edges to make parts safer.

Grinding is needed for aerospace fasteners, medical devices, and bearing surfaces. It helps precision machined parts meet top standards for quality and reliability.

Quality Control and Customization

KEMING uses advanced tools to check every part. They use CMMs for exact measurements. Optical comparators find defects. Surface testers check smoothness. Hardness testers check material strength. Non-destructive tests like ultrasonic and X-ray look for hidden problems.

KEMING changes its ways to fit each client’s needs. They pick the best materials, design parts with CAD, and choose the right machining ways. Their skill and technology help them give precision machined parts that match what customers want.

Materials Commonly Used in Precision Machined Components

Metals Materials for Precision Machined Industrial Parts

Metals are used a lot for precision machined parts. They are strong and last a long time. Engineers pick metals based on what the part needs to do. Some common metals are aluminum, stainless steel, brass, titanium, alloy steel, cast iron, and magnesium. Each metal has its own special traits for different uses.

Metal | Properties |

|---|---|

Aluminum | Lightweight, corrosion-resistant, easy to machine, cost-effective |

Stainless Steel | Excellent strength, corrosion resistance |

Brass | Good machinability, smooth finish, holds tolerances well |

Titanium | High strength-to-weight ratio, resistant to oxidation and heat |

Alloy Steel | Strong, durable, suitable for many applications |

Cast Iron | Good wear resistance, machinability |

Magnesium | Lightweight, good strength-to-weight ratio |

The metal you pick changes how easy it is to machine. Hard metals can wear out tools faster and need slow cutting. Softer metals are easier to cut but need careful work to stay accurate. Surface treatments like anodizing and plating help stop rust and make metals harder.

Engineers think about design, rules, and standards when picking metals. The right metal helps parts last longer and work better.

Plastics Materials for Lightweight Precision Machined Components

Plastics are important in precision machining. They are good for parts that must be light or resist chemicals. Some plastics used are ultra-high-molecular-weight polyethylene (PE), polyetheretherketone (PEEK), acrylonitrile butadiene styrene (ABS), polyamide (PA), and polyacetal (POM). These plastics are tough and safe for things like medical and food parts.

Property | Metals | Plastics |

|---|---|---|

Strength and Hardness | High strength and hardness | Low strength and hardness |

Machining Speed | Difficult to machine | Faster machining speeds |

Tool Wear | Fast tool wear | Less tool wear |

Weight | High weight | Light weight |

Corrosion Resistance | Poor corrosion resistance | Good corrosion resistance |

Surface Quality | Excellent surface quality | Susceptible to scratches and burrs |

Temperature Resistance | Good high temperature resistance | Poor temperature resistance |

Plastics cost less than metals and are lighter to ship.

They do not need extra finishing and resist chemicals.

Plastics can be machined faster and do not wear out tools as much.

Engineers use plastics for parts that must be safe, light, and easy to clean. These materials help meet design and safety rules in many fields.

Precision Machined Applications

Industry Uses of Precision Machining in Manufacturing

Precision machined parts are important in many fields. These fields need parts that are exact, strong, and safe. Some of the biggest users are:

Aerospace: Needs very exact parts for engines and landing gear.

Automotive: Uses these parts in engines, transmissions, and safety systems.

Medical Devices: Needs small limits for tools and implants.

Electronics: Needs tiny, detailed parts for circuit boards and connectors.

Defense: Needs strong, exact metal parts for weapons and vehicles.

Oil & Gas: Uses tough parts for pumps and valves in hard places.

Energy: Needs parts that work well in turbines and power systems.

Food Processing: Needs safe, easy-to-clean parts for machines.

The market for precision machining is growing quickly. In 2024, it was about USD 114.58 billion. Experts think it will double by 2033 as more fields need good parts.

Examples of Common Precision Machined Components Used

Precision machining makes many kinds of parts. These parts must fit right and work in hard jobs. Here are some examples:

Component Type | Industry | Description |

|---|---|---|

Gears | Automotive | Good gears help move power smoothly |

Transmission Components | Automotive/Aerospace | Needed for electric cars and planes |

Aerospace Components | Aerospace | Made with CNC machines for high accuracy |

Engine Components | Automotive | Laser-cut for better work and trust |

Medical Devices | Medical | Tools and implants with small limits |

Battery Components | Electronics | Tiny, detailed parts for storing energy |

Lighting Systems | Automotive/Electronics | Custom parts for new lighting systems |

KEMING makes these parts with advanced CNC machines and casting. Their team follows strict rules for accuracy and finish.

Benefits of Precision Machined Parts in Production

Precision machined parts give many good things to makers and users:

High accuracy helps products work better and safer.

Small limits make sure parts fit and work right.

CNC machining cuts waste and saves materials.

Machines lower the chance of injuries at work.

Custom parts allow for special shapes and needs.

Good parts mean less downtime and fewer repairs.

KEMING’s special process gives parts with top quality and steady results. Their skill helps clients in tough fields like aerospace and medical devices get the best outcomes.

Precision machined parts are important in many industries. They help machines work well and last longer. Companies use these parts to follow safety rules. This lowers the chance of things breaking.

Precision machining makes systems work better in aerospace and other areas.

Strong parts break less often and help keep people safe.

Saving money happens because there is less waste and fewer fixes.

Custom designs let engineers make new ideas.

KEMING gives top-quality parts using advanced tools. Makers who pick precision machining get better products and stronger results.

FAQ

What does “precision machined part” mean?

A precision machined part is made with exact sizes. Machines shape it so it fits with other parts. These parts help products work well and last longer.

Why do industries need tight tolerances?

Tight tolerances make sure parts fit with no gaps. This helps machines work smoothly. Aerospace and medical fields need tight tolerances for safety.

Which materials work best for precision machining?

Metals like aluminum, stainless steel, and titanium work well. Plastics like PEEK and ABS are also used. Engineers pick materials for strength, weight, and use.

Tip: Picking the right material helps the part last longer and work better.

How does KEMING ensure quality in every part?

KEMING uses advanced machines and strict checks. Workers measure each part with special tools. They follow rules to make sure each piece meets needs.

Can precision machined parts be customized?

Yes, engineers can design parts for special jobs. KEMING offers custom shapes, sizes, and finishes. This helps clients get what they need for their projects.