Automotive castings make your car last longer. They give your car strong and dependable parts. You count on these good parts to keep your car safe. They also help your car run well. If you learn more about castings, you can make better choices. This helps when you need to fix or replace parts. KEMING is a leader in investment casting for cars. They offer trusted answers for what your car needs.

Key Takeaways

Automotive castings make strong and dependable parts. These parts help your car stay safe and work well. Regular checks and care of cast parts help them last longer. This also stops expensive fixes. Picking good casting methods, like investment casting, gives you exact and tough parts for your car. Using light materials in automotive castings helps your car use less gas. It also makes your car work better. Knowing about different casting ways helps you choose wisely when you fix or change car parts.

Automotive Castings Overview

What Are Automotive Castings

Most cars have automotive castings. These parts start as melted metal. The metal gets poured into special molds. The molds shape the metal into strong pieces. There are three main ways to make these parts: die casting, investment casting, and sand casting.

Here is a table that shows how these casting methods are different:

Casting Method | Mold Type | Surface Finish | Part Complexity | Production Volume |

|---|---|---|---|---|

Sand Casting | Sand mold | Rougher finish | Moderate complexity | Low to medium volume |

Die Casting | Metal molds | High-quality finish | High dimensional accuracy | High volume |

Investment Casting | Disposable molds | Exceptional finish | Highly complex geometries | Low to medium volume |

Automotive die casting uses metal molds. These molds make parts smooth and exact. Aluminum die casting makes parts that are light and strong. Investment casting is used for very detailed shapes. Sand casting works for bigger parts that do not need a perfect finish. Gray iron casting is used for heavy-duty parts.

Why They Matter in Automotive

Automotive castings are very important for cars. You need these parts for safety and good performance. The casting process makes parts with great detail and accuracy. This means automotive die cast components fit well and last longer.

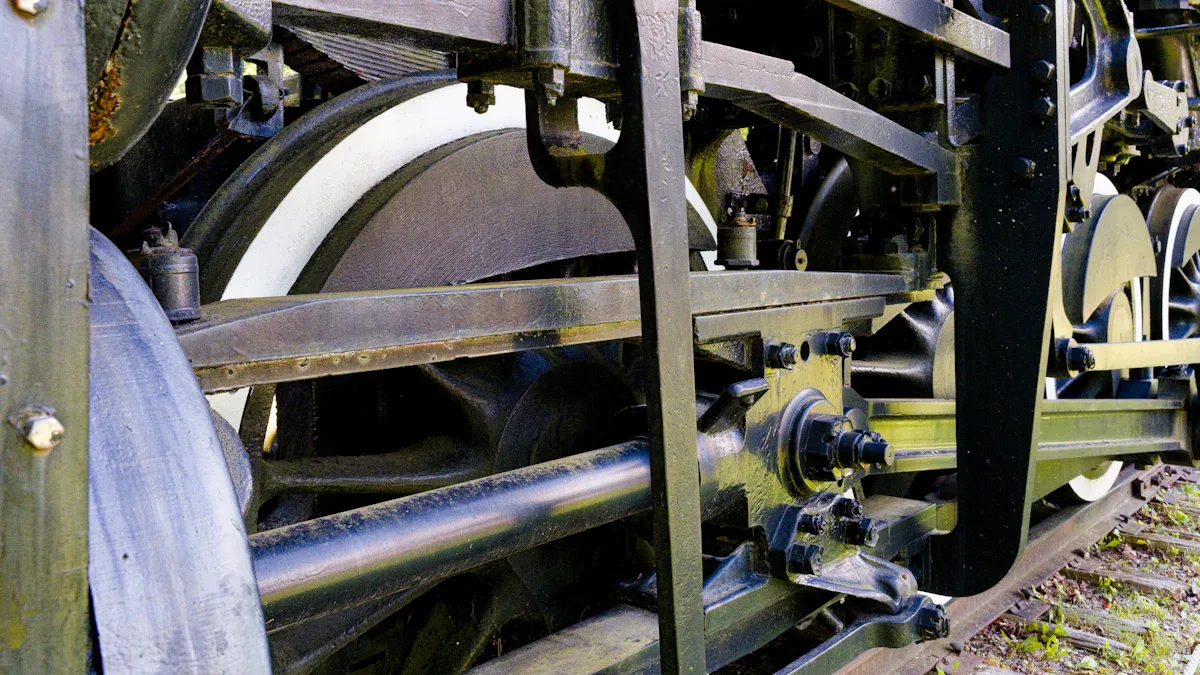

You see automotive die casting in engine blocks, transmission housings, and suspension parts. Aluminum die casting keeps cars light and strong. It also stops rust and handles stress. Automotive die cast components can hold heavy loads and high heat. This is important for parts that keep you safe.

Note: The automotive castings market is getting bigger. Experts think it will reach almost USD 90 billion by 2030. This shows automotive manufacturing will be important in the future.

Automotive makers test cast parts carefully. They look for air bubbles, weak spots, and marks on the surface. These tests make sure every part is safe. Aluminum die casting and the die casting process help you get strong parts. These parts help your car last longer.

Key Automotive Components

Engine and Transmission Parts

Many car parts are made using casting. About 15% to 20% of car parts use this method. More than 70% of the aluminum in cars comes from castings. Cast aluminum is 77% of all aluminum alloys in cars. The engine and transmission need strong and exact parts. Casting is used in these main areas:

Engine blocks: Sand casting or investment casting makes them strong.

Cylinder heads: Sand casting or die casting shapes them for better engines.

Transmission housings: Die casting makes them light and accurate.

Brake calipers: Die casting forms them for detailed shapes.

Intake and exhaust manifolds: Sand casting or investment casting helps them handle heat.

Engine blocks and cylinder heads face high pressure and heat. Casting helps these parts last longer and work better. Powertrain and transmission parts made with casting help your car run well.

Suspension and Steering

Suspension and steering parts go through hard use every day. These parts must be strong and dependable. Makers use cast iron, aluminum, and steel for these parts. Casting lets them make complex shapes that handle stress. Suspension arms, control arms, and steering housings use casting. Heat-treated castings make your ride safer and smoother.

Tip: Cast suspension and steering parts often last longer and cost less than other types.

Other Critical Components

Many other car parts use casting for strength and detail. Here is a table with some examples:

Component Type | Material Used | Description |

|---|---|---|

Control Arms | Magnesium Alloy | Light, strong, helps with handling and ride. |

Door Handles | Zinc Alloy | Detailed, looks nice inside the car. |

ECU Housings | Magnesium Alloy | Good at cooling, protects electronics. |

Mirror Housings | Aluminum Alloy | Does not rust, stands up to weather. |

Covers and Housings | Aluminum Alloy | Strong, light, helps the powertrain work better. |

You can find casting in many car parts, from the engine to the powertrain. These parts help your car last longer and work well.

Durability Benefits

Strength and Heat Resistance

You want your car to last a long time. Automotive castings are strong and resist heat well. These parts help your car handle tough roads and hot engines. Castings can be made into big and complex shapes. This means engine blocks and transmission housings are strong. They face high pressure and heat every day.

Here is a table that compares casting and forging:

Process | Advantages | Disadvantages |

|---|---|---|

Casting | Allows for complex shapes and large components | Can lead to porosity and metallurgical defects |

Forging | Superior strength and durability | Limited to simpler shapes |

Cast automotive parts are strong if made with good alloys and heat treatment. You see these strong parts in engine blocks and suspension arms. Forged parts are even stronger and last longer. But castings can be shaped in more ways. Cast parts fit your car well and work under stress.

Cast parts get strong with good alloys and heat treatment.

Forged parts are about 26% stronger than cast parts.

Forged parts last about 37% longer than cast parts.

Castings can have problems like voids or shrinking, but new methods help stop this.

Automotive castings resist heat. Aluminum and iron castings work in hot engines and exhausts. Your car works well even when it gets very hot.

Tip: New casting methods use vacuum casting and better molds. This helps stop defects and makes parts last longer.

Wear Protection

Wear protection helps your car run smoothly. Automotive castings resist wear if you use the right materials and methods. Cast chilled iron and compacted graphite iron (CGI) are good for engine blocks and brake parts.

Here is a table showing wear resistance for different casting methods and materials:

Component Type | Wear Resistance | Mechanical Properties | Notes |

|---|---|---|---|

Cast Chilled Iron | Excellent | High | Graphite flakes absorb vibration and provide self-lubrication. |

Gray Iron | Moderate | Moderate | More brittle due to stress points from graphite flakes. |

Centrifugal Casting | High | Superior | Clean microstructure improves wear performance. |

Squeeze Casting | High | High Strength | Meets high strength and elongation needs, limited use. |

Centrifugal casting helps parts last longer. It improves wear by 70.4%. You need to replace these parts less often. Castings with even microstructures resist wear better. Your car stays reliable.

Automotive castings also protect against common problems. New casting methods help stop porosity, shrinking, and inclusions. Regular checks and good molds help too. Here is a table that shows how defects are managed:

Casting Defect | Causes | Mitigation Strategies |

|---|---|---|

Porosity | Gas absorption, poor mold design | Proper venting, vacuum casting, control pouring temperature |

Shrinkage Defects | Uneven cooling, thick sections | Good gating, consistent cross-sections, quality mold materials |

Cold Shuts | Low pouring temperature, poor gating | Increase temperature, optimize gating, use correct alloy |

Mold Shifting | Poor alignment, mold wear | Regular inspection, precise clamping, high-precision molds |

Hot Tears | Uneven cooling, thick areas | Uniform cooling, control rates, low thermal expansion materials |

Inclusions | Contaminated metal, poor handling | High-quality materials, slag removal, filtration systems |

You get tough car parts when you use advanced casting methods. These parts resist wear, absorb vibration, and help stop breakdowns.

Note: Castings that absorb vibration and self-lubricate help your car run smoother and quieter.

KEMING Investment Casting in Automotive Industry

Advanced Casting Solutions

You want your car to last longer. You also want it to work better. KEMING helps with advanced casting solutions for cars. You get strong and light parts from modern processes. KEMING uses investment casting, shell casting, lost foam casting, and lost wax casting. Each process gives special benefits for car parts.

Investment casting makes parts that are very exact and light. This process is great for making light cars.

Shell casting is a cheaper way to make tough parts.

Lost foam casting lets you make tricky shapes with less waste. This helps car makers who want fast production.

Lost wax casting makes detailed parts with smooth surfaces. This process is good for parts that need fine details.

You can pick from many materials for your car parts. KEMING uses zinc, aluminum, and magnesium. These materials help you get parts that are light, strong, and dependable. The table below shows what each material does best:

Material | Advantages |

|---|---|

Zinc | Very strong, fights rust, keeps shape, good for the planet. |

Aluminum | Light, saves money, does not rust, safe under stress, good for nature. |

Magnesium | Light, tough, fights rust better, moves heat well. |

These materials help car makers build light parts for light cars. You get parts that last longer and help your car work better.

Quality and Innovation

You want your car parts to be high quality. KEMING makes sure of this with strict checks. Every step uses advanced tests to meet top standards. The table below shows how KEMING checks each part:

Testing Method | Purpose |

|---|---|

Hardness Testing | Checks if the part is hard enough |

X-ray Inspection | Finds hidden problems like air bubbles |

Magnetic Particle Testing | Spots surface cracks or breaks |

Dye Penetrant Inspection | Shows surface flaws without hurting the part |

You can trust KEMING because they follow big industry rules. Car makers count on KEMING’s certifications:

IATF 16949: Makes sure products are safe and reliable for cars.

ISO 9001: Helps customers and makes work better.

ISO 14001: Cares for the environment in car making.

KEMING’s process gives you parts that last longer and meet world standards. You help the planet and get better performance. When you pick KEMING, you get quality, new ideas, and trust for every car part.

Maintenance Tips for Automotive Castings

Inspection and Care

You can make your car parts last longer with regular care. Always follow the schedule from the manufacturer. Most experts say to check cast parts every six months. You should also check them every 5,000 to 7,500 miles. If you drive in rough places or have an old car, check more often. Look for wear, rust, or cracks.

Here are some easy ways to keep cast parts working well:

Pick the casting process that fits your needs. Permanent mold casting makes stronger parts.

Use surface treatments like anodizing or powder coating. These help stop rust and wear.

Put covers or coatings on parts. This keeps water and dirt away.

Check and fix your parts often. Early checks help you find problems fast.

Fix small scratches or chips right away. This stops bigger problems from happening.

Choose good materials and smart designs for your parts. Good choices help parts last longer.

Store parts in a safe place. Too much heat or cold can cause cracks.

Tip: Taking care of your parts helps the planet. When parts last longer, you make less waste.

When to Replace

Knowing when to change cast parts keeps your car safe. Watch for these signs:

Lights flicker or dashboard acts strange

Gauges move in odd ways

Power drops or jumps suddenly

Your car stops without warning

If you see any of these, check your parts soon. Changing old parts on time keeps your car working well. You can avoid sudden problems and big repair bills. Regular checks and quick replacements also help the planet by making less waste.

This table shows why good care is important:

Benefit | Result |

|---|---|

Regular inspections | Find problems early |

Timely replacement | Fewer breakdowns, safer driving |

Good care | Parts last longer, less waste |

Attention to detail | Better performance, more sustainability |

Note: Caring for your car parts saves money and helps the earth. You get a smoother ride and help the planet too.

Automotive castings help your car last longer by giving you strong, reliable parts. When you choose high-quality cast components from trusted companies like KEMING, you get many benefits:

Benefit | Description |

|---|---|

Complex Shapes Made Easily | You get parts with special designs that fit your car perfectly. |

High Strength and Durability | These parts handle heavy loads and high heat, keeping you safe. |

Lightweight Design | Lighter parts help your car use less fuel and perform better. |

Keep up with regular care and always pick quality parts. Your car will stay safe, run smoothly, and last for years.

FAQ

What is the main benefit of using cast parts in your car?

You get strong, precise parts that last longer. Cast parts handle heat and stress well. They help your car run safely and smoothly for many years.

How do you know when to replace a cast automotive part?

You should check for cracks, rust, or odd noises. If you see leaks or feel changes in how your car drives, replace the part soon.

Can you use different metals for automotive castings?

Yes. You can choose from aluminum, iron, steel, or magnesium. Each metal gives your car different benefits like strength, light weight, or rust resistance.

Why do car makers prefer investment casting for some parts?

Investment casting makes very detailed and accurate parts. You get smooth surfaces and complex shapes. This process works well for parts that need high precision.

How can you make cast parts last longer?

Tip: Clean parts often. Check for damage. Use protective coatings. Follow your car’s maintenance schedule. This helps you avoid early wear and keeps your car safe.