Aluminum CNC machining uses machines run by computers to shape aluminum into exact parts. CNC machining helps companies make strong, light, and accurate pieces. Many people pick aluminum because it has many good points:

Easy machinability means it needs less force to cut and makes parts faster.

Superior surface finish means the parts have fewer flaws.

High machining precision keeps shapes very close to the right size.

Longer tool life and cooler cutting help save money.

These features make aluminum a great choice for many CNC jobs.

Key Takeaways

Aluminum CNC machining uses machines run by computers. These machines make aluminum parts fast and very accurately.

Aluminum is a good choice for machining. It is light, not too expensive, and easier to use than other metals.

Picking the right aluminum alloy is very important. Different alloys have different strengths and uses for certain jobs.

CNC machining uses milling, turning, and drilling. These processes help make complex shapes with great accuracy.

Quality control is very important in CNC machining. It makes sure parts are made right and work well for their jobs.

Aluminum CNC machining basics

What is CNC machining?

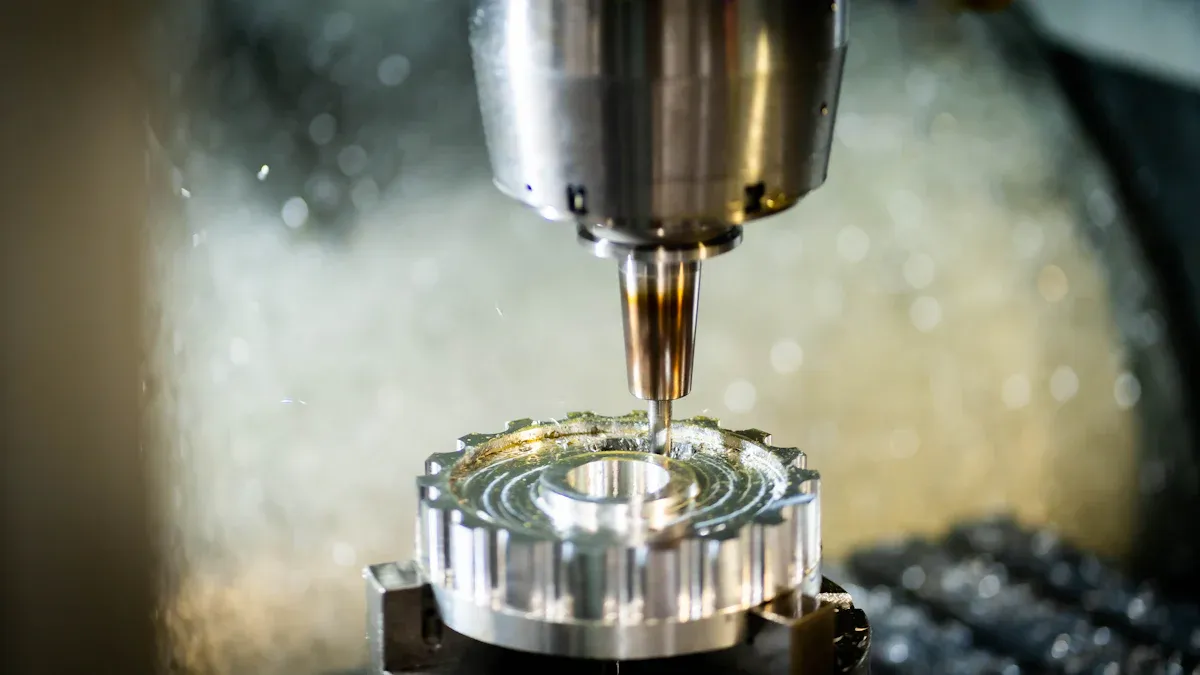

CNC machining uses computers to control machines. These machines shape materials into exact parts. The process starts with a digital design. The machine reads the design and follows instructions. It cuts, drills, or shapes the material. CNC machines work with many materials. Aluminum is special because it has unique features.

CNC machines use special tools for aluminum.

The technology can make parts very exact, even 0.01 mm close. This is important for things like airplanes and electronics.

Smart software and tools help CNC machines make hard shapes. This means less mistakes and less wasted material.

CNC machining lets companies make custom parts fast and very accurately.

Why choose aluminum for CNC machining?

Aluminum is a top pick for CNC machining. Many industries like it more than metals like steel or titanium.

Material cost: Aluminum is cheaper to buy and use than titanium.

Machining speed: Aluminum is softer, so machines cut it faster. This saves time and money.

Tool wear: Aluminum does not wear out tools as fast. This means less money spent fixing or replacing tools.

Post-processing: Aluminum often needs less work after machining. This also saves money.

These reasons make aluminum cnc machining a smart choice for projects that need good quality and speed.

Key properties of aluminum alloys

Aluminum alloys have special features that are great for cnc machining. Each alloy has its own mix of strength, machinability, corrosion resistance, and workability. The table below shows how some common alloys compare:

Alloy Type | Strength | Machinability | Corrosion Resistance | Workability |

|---|---|---|---|---|

6061 | Moderate | High | Good | Good |

7075 | High | Moderate | Moderate | Moderate |

A356 | Low | High | Moderate | High |

5083 | Moderate | Moderate | Excellent | Moderate |

6063 | Low | High | Excellent | High |

Tip: Pick the right alloy for your project needs. For example, 7075 is strong and good for airplane parts. 6061 works well for many different uses.

Common aluminum alloys for CNC

There are many aluminum alloys used in cnc aluminum machining. Some of the most common are:

Aluminum alloy 2024-T4

Aluminum alloy 7075-T6

Aluminum alloy 6082

Aluminum alloy 6061

Aluminum alloy MIC 6

Al-2007 Series

Al-5083 Series

Al-5754 Series

Al-6060 Series

Al-6061 Series

Al-6082 Series

Al-7075 Series

These alloys are used a lot in cnc machined aluminum parts. They are found in cars, airplanes, and electronics. Each alloy has its own strengths. This makes aluminum cnc machining useful for many different jobs.

CNC aluminum machining processes

CNC milling of aluminum

CNC milling cuts aluminum blocks into exact shapes. The machine spins sharp tools to take away metal. This makes flat areas, grooves, and tricky shapes. CNC milling is fast and very accurate. Most shops can keep sizes within ±0.005 inches (±0.127 mm). Some jobs need even smaller limits, under ±0.001 inches. To do this, workers must set the machine just right.

CNC-milled aluminum parts often have tool marks you can see. But this process gives the best size control without extra cost. Many companies use CNC milling to make easy or hard aluminum parts fast.

Tip: Pick the best aluminum alloy and set the machine for your part.

CNC turning for aluminum parts

CNC turning spins an aluminum rod while a tool shapes it. This makes round things like shafts, bushings, and rings. CNC turning works for both small and big batches. But workers face some problems with aluminum.

Workers use special holders and tools to fix these issues. They also watch the machine closely to keep sizes correct.

Drilling and tapping aluminum

Drilling makes holes in aluminum parts. Tapping cuts threads inside the holes for screws or bolts. Aluminum is soft, so drilling and tapping go fast. Workers use high speeds and steady feeds for clean holes.

For drilling, 50 surface feet per minute is good. A feed of 1 thread pitch per turn is common.

Cast alloys: 60 SFM

Diecast alloys: 70 SFM

Wrought alloys: 80 SFM

These speeds help tools last longer and keep holes neat. Clean holes and threads help parts fit together and stay strong.

Specialized CNC techniques for aluminum

Workers use special CNC methods to make aluminum cnc machining better. These ways help control heat, clear chips, and keep parts exact.

These special ways make cnc machined aluminum parts more exact and strong. They also cut down on waste and make parts faster.

Note: Using the right method for each step gives the best results in cnc aluminum machining.

Workflow of aluminum CNC machining

CAD design and preparation

Engineers always begin with a careful plan. They use CAD software to make a digital part model. The design process has important steps:

Change tolerances to fit the part’s shape and tool use.

Pick the best aluminum alloy for strength and use.

Only add features that need tight tolerances.

Remove extra material to save time and money.

Use standard features so there are fewer sizes.

Choose the surface finish for the part.

Make sure the design is strong enough for machining.

Let standard cnc tools reach all areas easily.

These steps help make cnc machined aluminum parts that are accurate and save money.

CNC programming and setup

After designing, programmers write instructions for the cnc machine. They use special software to turn the CAD model into machine code. This step is important for aluminum cnc machining because:

CNC machining uses advanced technology and skilled workers to keep parts exact.

Tight tolerances, even as close as ±0.0005 inches, are possible.

Real-time monitoring during setup helps find mistakes early.

Operators make sure the final part meets all needs.

Good programming and setup help get high-quality cnc aluminum machining results.

Machining and real-time monitoring

The cnc machine shapes the aluminum part by cutting, drilling, or milling. Operators watch the process closely. They use real-time monitoring tools to spot problems. Common technologies include:

Technology Type | Description |

|---|---|

Sensors | Devices like force sensors and vibration sensors track tool wear. |

Data Analytics | Machine learning and data analysis predict when tools need changing. |

Connectivity | IoT systems share data between machines and computers. |

These tools help keep the machining process smooth and the quality high.

Post-processing and finishing

After machining, the aluminum part often needs extra steps to look and work better. Common post-processing methods include:

Anodizing makes the part harder and stops rust.

Powder coating gives a tough, colorful finish.

Electroplating makes the part look nice and protects it.

Other finishing steps like polishing can make the surface smoother and shinier. These methods help cnc machined aluminum parts last longer and look better.

Pros and Cons of CNC Machined Aluminum

Benefits of aluminum CNC machining

Aluminum cnc machining has many good points for factories. Companies like this process because it saves both time and money.

Aluminum is easier to cut than most other metals. This lets workers make parts faster and spend less.

It costs less to machine aluminum than steel or titanium. Tools last longer and use less power.

CNC machining is very exact, quick, and can do many jobs. It can make hard shapes that other ways cannot.

The table below shows how cnc machined aluminum helps in places like car and airplane factories:

Benefit | Description |

|---|---|

Lightweight Components | CNC machining makes light aluminum parts for better gas mileage. |

Durability | The process makes strong parts that last a long time. |

Complex Geometries | It lets workers make tricky shapes that are still strong but weigh less. |

High Strength-to-Weight Ratio | Aluminum alloys like 2024 and 7075 are strong but not heavy. |

Applications in Aerospace | Used for brackets and landing gear in airplanes. |

Applications in Automotive | Used for frames and engine blocks in cars. |

Common machining challenges

Machining aluminum can be tricky sometimes. Different grades of aluminum have different hardness. Some are soft and can bend or change shape. Aluminum also moves heat quickly, which changes how it acts when being cut.

Aluminum can stick to the cutting tool and make a sticky mess. This happens because it melts at a low temperature.

This sticky stuff can stay on the tool and make cutting harder.

Built-up edge (BUE) is a common problem when cutting aluminum. BUE happens when aluminum sticks to the tool, making the surface rough and cuts less exact.

Cooling and heat management

Good cooling is needed for aluminum cnc machining. Using coolant at room temperature helps stop thermal shock and sticky buildup.

Lots of coolant helps when cutting fast.

High-pressure, flood, or mist cooling all work well.

Putting the coolant nozzle in the right place cools the tool and part.

Steady coolant flow helps tools last longer and keeps things running well.

Quality control and precision

Quality control is very important in cnc machining. Companies check machines often to keep them working right. They use good aluminum alloys to stop problems. Special tools help get very close sizes.

Workers use calipers and micrometers to measure.

Coordinate Measuring Machines (CMM) check tricky shapes.

Surface testers check how smooth the part is.

Keeping the shop controlled helps keep parts exact. Meeting rules like ISO 9001 and AS9100 keeps every cnc machined aluminum part safe and high quality.

Aluminum CNC Machining Applications

Industries using CNC machined aluminum

Many companies use aluminum CNC machining for strong, exact parts. Car makers use CNC machines for engine blocks and frames. Aerospace companies make brackets and landing gear with CNC. Medical device makers need CNC aluminum for tools and equipment. Engineering firms use CNC for custom parts in electronics and machines. The CNC market is growing fast. It may reach USD 80.4 billion by 2028. More electric cars and light materials mean more CNC use in car factories.

Automotive: Engine parts, frames, transmission pieces

Aerospace: Brackets, landing gear, structural parts

Medical devices: Surgical tools and equipment

Precision engineering: Custom parts for electronics and machines

Choosing the right aluminum alloy

Picking the best aluminum alloy depends on many things. Engineers look at what the project needs. They check for corrosion resistance, strength, and conductivity. Machinability is important for tricky designs. Cost and supply matter because some alloys cost less. Strength makes sure the part works under stress. Corrosion resistance helps parts last in tough places. Budget limits also help decide which alloy to use.

Project needs: Corrosion resistance, strength, conductivity

Machinability: Easy to machine for hard shapes

Cost and supply: Price and how easy to get

Strength: Holds up under stress

Corrosion resistance: Handles tough environments

Budget: Stays within project money

Design tips for CNC aluminum machining

Designers can make CNC aluminum machining easier and cheaper. They keep designs simple to cut down on hard machining. Simple 2.5D shapes let machines work in one setup. Avoiding tiny features stops vibration problems. Leaving out text and letters saves money. Picking materials that are easy to machine and cost less helps. Fewer surface finishes lower costs. Using standard blank sizes cuts down on waste. Ordering more parts at once makes each part cheaper.

Tip: Simple designs and smart material choices make CNC aluminum machining faster and more affordable.

KEMING’s investment casting and CNC services

KEMING is a leader in aluminum CNC machining. The company uses advanced CNC machines for custom projects. KEMING mixes investment casting with CNC for exact and complex parts. The shop uses cold processing and precision machining for many metals. Quality checks include hardness tests and surface checks. They use optical comparators and 3D measuring machines. Non-destructive tests like ultrasonic and X-ray find defects. KEMING keeps strict inspection steps and records for tracking and improvement.

Feature | KEMING’s Services | Competitors’ Services |

|---|---|---|

Investment Casting | Precise dimensions and complex shapes | Varies by provider |

CNC Machining | Modern equipment for tight tolerances and superior finishes | Often less advanced technology |

Quality Control | Strict quality management with ISO9001 certification | Varies, not always certified |

Experience | Over 20 years in the industry | Varies by company |

KEMING’s way makes complex aluminum parts with high accuracy and smooth surfaces. The company gives faster delivery and steady quality for car, plane, and other industries.

Aluminum CNC machining has many good points. It is easy to machine, does not rust easily, and saves money.

Picking a skilled company helps get the right tools and quick delivery. Good companies check quality at every step. KEMING uses new machines and checks parts carefully for accuracy. People can learn about new CNC and casting ideas to get ready for the future.

FAQ

What is the main advantage of aluminum in CNC machining?

Aluminum is easy to shape and not heavy. Many companies use aluminum because it makes parts quickly. The metal does not rust and looks smooth when finished.

Which industries use CNC machined aluminum parts?

Car makers, airplane builders, doctors, and electronics companies use CNC aluminum. These groups need parts that are strong, light, and fit well.

How does CNC machining ensure part accuracy?

Workers use smart machines and special measuring tools. Sensors and computer programs watch the work. Careful checks make sure every part is made right.

Can CNC machines work with other metals besides aluminum?

Yes, CNC machines can shape steel, titanium, brass, and copper. Each metal needs its own tools and machine settings for good results.