Sand casting has three main types. These are green sand, dry sand, and shell mold sand casting. Keming Machinery is a top company in Shell Mold Sand Casting. Their team makes strong castings for many industries. Readers can see how each casting type works for different needs. They can also find out which process is best for their own projects.

Key Takeaways

Green sand casting is flexible and saves money. It uses wet sand mixed with clay. This method works for easy and hard shapes.

Dry sand casting makes stronger molds by baking the sand. It is best for big and heavy parts. It gives better size accuracy.

Shell mold sand casting makes smooth and exact parts with resin-coated sand. It is great for detailed designs and tight fits.

Picking the right casting method depends on part size, shape, and finish. Think about what your project needs.

Keming Machinery does shell mold sand casting. They make good parts for many industries, like cars and planes.

Green sand casting basics

What is green sand casting

Green sand casting is a very old way to make metal parts. People started using it more than 3,000 years ago. Ancient Mesopotamia and China used this method first. In the Middle Ages, people made bells and weapons with sand casting. Later, the industrial revolution made sand casting even more popular. It was used for iron and steel items.

Green sand is a mix of silica sand, clay, water, and sometimes organic stuff. The word “green” means the sand is wet, not colored green. The moisture helps keep the sand mold soft and easy to shape. Workers pack the sand mix around a pattern. This makes the mold for the metal part. Clay and water help the sand stick together. This makes it simple to mold and use again.

Good green sand needs the right mix of things. Permeability means air can move through the sand. This helps make better castings. Green compression strength shows how much pressure the sand can take. Mixing new and recycled sand, clay, and water makes strong molds. This gives good results for casting.

Green Sand Casting: A Versatile Solution for Various Industries

Automotive Castings: In the automotive industry, green sand casting is frequently used to produce engine blocks, cylinder heads, and other vital engine components. Its cost-effectiveness and ability to handle large production volumes make it ideal for manufacturers looking to create high-quality parts at a competitive price.

Marine Industry Castings: Green sand casting is also a go-to choice for marine applications where strength and corrosion resistance are paramount. Components such as propellers, pump housings, and engine parts for boats and ships are commonly manufactured using this method, providing long-lasting performance even in harsh, saltwater environments.

Railroad Castings: For the railroad industry, green sand casting is utilized to produce durable components such as train wheels, brake parts, and rail joints. These parts need to withstand immense pressure and wear over time, making green sand casting an ideal choice due to its excellent material strength and ability to produce large, heavy components.

Agricultural Castings Parts: In agriculture, green sand casting plays a crucial role in manufacturing various machinery parts, such as gears, plows, and engine components for farm equipment. The durability and flexibility of green sand casting ensure that agricultural machinery parts can endure heavy use in challenging conditions, boosting productivity and efficiency.

Features and uses of green sand casting

Green sand casting has many important features:

Versatility: It can make simple or complex shapes. It also works for parts with detailed gating systems.

Durability: The sand mix can handle high heat. It keeps its shape during casting.

Sustainability: Most of the sand can be recycled and used again. This makes it good for the environment.

Cost-effectiveness: Sand is easy to find and cheap. This helps keep costs low.

Tip: Green sand casting is flexible. It can make tiny parts or very large ones.

Many industries use green sand casting for different products. The table below shows some examples:

Industry | Typical Products | Applications | Advantages |

|---|---|---|---|

Automotive | Cylinder heads, engine blocks | Engine manufacturing | High accuracy, cost-effective |

Aerospace | Turbine housings | Aircraft engine components | Complex shapes, smooth finish |

Construction | Manhole covers, grates | Urban infrastructure | Durable, recyclable |

Energy | Wind turbine components | Renewable energy | Sustainable production |

Marine | Boat engine blocks | Marine solutions | Corrosion resistance |

Green sand casting is still used by many companies. It is popular because it is traditional, flexible, and efficient.

Dry sand casting explained

Dry sand casting process

Dry sand casting uses a mold that gets dried before pouring metal. Workers mix sand with a binder to make the mold. They put the mold in an oven to bake it. Baking takes out water and makes the mold hard. This makes the mold stronger than green sand molds.

After baking, workers take out the pattern from the mold. The mold now has a space shaped like the final part. Next, they pour hot metal into the space. The metal fills the mold and copies its shape. The metal cools and gets hard inside the mold. When the metal is solid, workers break the mold to get the finished part.

The table below shows the main steps in dry sand casting. It also shows how these steps are different from green sand casting:

Step | Dry Sand Casting | Green Sand Casting |

|---|---|---|

1 | Mold Mix | Positioning the Mold Pattern |

2 | Baking | Establishing the Gating System |

3 | Pattern Removal | Positioning the Cope and Sprues and Completing the Fill |

4 | Pouring of Molten Metal | Extracting the Mold Pattern |

5 | Solidification / Cooling | Venting the Cope, Reassembling the Flask, and Preparing for Fill |

6 | Removal of Sand Mold | Introducing Molten Metal into the Mold Cavity |

7 | N/A | Cooling |

8 | N/A | Extracting the Cast |

Note: Baking the mold in dry sand casting makes it stronger. This helps the mold keep its shape when metal is poured.

Advantages and applications

Dry sand casting has many good points. The baked mold is stronger and more stable. This lowers the chance of the mold breaking during casting. The process gives a smoother surface and better size accuracy than green sand casting. Dry sand molds can hold bigger and heavier castings. This makes them great for large industrial parts.

Many industries use dry sand casting for important parts. The table below lists some common uses:

Industry | Applications |

|---|---|

Automotive | Engine blocks, transmission cases, cylinder heads, heavy vehicle parts |

Aerospace | Aluminum sand-cast parts for aircraft and space vehicles |

Energy and Power | Turbine housings, pump casings, valves |

Construction Machinery | Excavator buckets, gearboxes, bulldozer blades, crane components |

Some examples are:

Automotive: Prototypes, engine blocks, cylinder heads, EV parts

Aerospace: Light aluminum parts

Energy: Turbine housings, pump casings

Construction: Heavy machine parts

Dry sand casting is good for making strong, accurate, and big metal parts. Many companies pick this method for jobs that need tough and exact parts.

Shell Mold Sand Casting overview

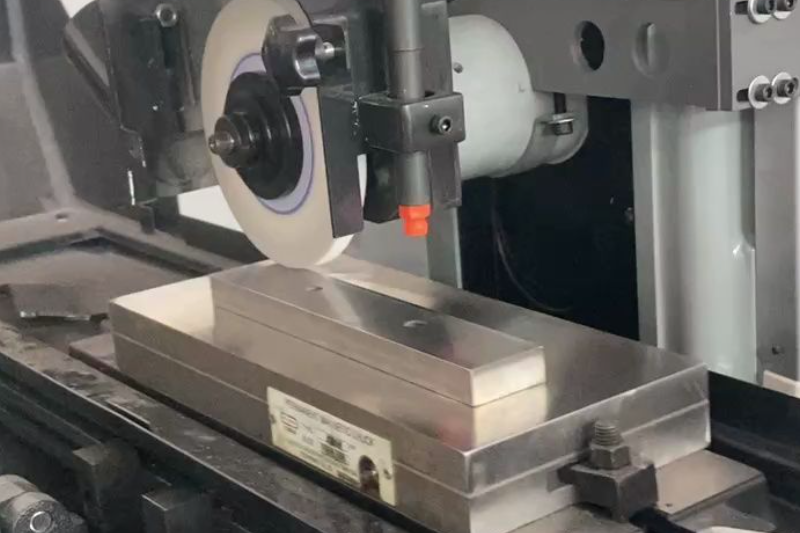

Shell mold sand casting process

Keming Machinery uses Shell Mold Sand Casting to make metal parts that fit exactly. First, workers make a copy of the part. They put a release agent on the pattern. Then, they cover it with sand mixed with resin. The pattern gets heated. This makes the resin hard and forms a thin shell. The shell mold goes into an oven to get stronger. Workers take the mold off the pattern. The mold keeps the same shape as the pattern. They heat the mold before pouring in hot metal. The metal cools and gets solid. At the end, workers break the shell to get the finished part.

Using sand with resin in Shell Mold Sand Casting makes a hard shell. The shell matches the part’s shape. This way, the part has a smooth surface and keeps its size well.

Process Steps:

Make the pattern

Put together the mold with resin-coated sand

Heat to build the shell

Cure the mold

Remove the mold

Pour in hot metal

Cool and let the metal get hard

Break off the shell

Shell Mold Sand Casting can make parts with thin walls and exact sizes. It works for shapes that are tricky and have lots of details.

Benefits and industry uses

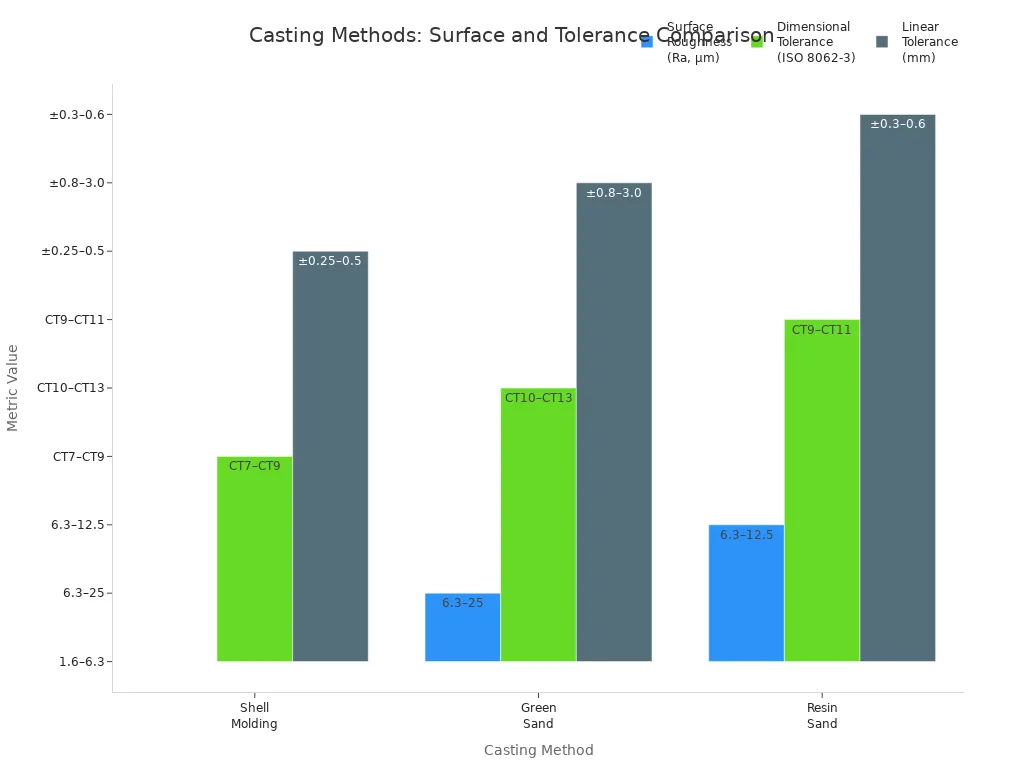

Shell Mold Sand Casting has many good points. It makes parts with smooth surfaces and very exact sizes. The chart below shows how the surface and size compare to other sand casting ways.

Keming Machinery uses different metals for Shell Mold Sand Casting. Each metal works best for certain jobs.

Alloy Steel Grade | Characteristics |

|---|---|

20Mn | Changes in weight and strength |

45Mn | Stops rust well |

ZG20Cr | Handles high heat |

40Cr | Tough and strong |

20Mn5 | Saves money |

16CrMo4 | Great for heavy-duty jobs |

42CrMo | Used in many fields |

40CrV | Good for car parts |

20CrNiMo | Very strong and tough |

GCr15 | Used for bearings |

9Mn2V | For top performance |

Many industries use Shell Mold Sand Casting. These include cars, machines, and electrical gear. Common products are engine blocks, gears, valves, and brake parts.

Industry | Typical Products |

|---|---|

Automotive | Engine blocks, transmission housings, brake parts |

Wear Resistant parts | Castings that resist wear and are very hard |

Industrial machinery | Gears, valves, pump housings |

Electrical equipment | Cases for electrical systems |

Keming Machinery cares about making good parts. They test for hardness, use X-rays, and check with magnets. Their Shell Mold Sand Casting makes strong parts that do not rust easily. Keming gives custom casting choices for every customer.

Comparing sand casting types

Key differences and similarities

Sand casting has three main methods. Each uses sand to make molds for metal parts. Workers pack sand around a pattern. They take out the pattern. Then, they pour hot metal into the mold. The three methods have special features.

Green sand casting uses wet sand mixed with clay. It costs less and is good for making many parts. Dry sand casting bakes the mold. This makes it stronger for big or heavy parts. Shell Mold Sand Casting uses sand with resin. Heat makes a hard shell. This method gives parts smooth surfaces and exact sizes.

Casting Type | Process Characteristics | Cost (USD/ton) | Product Quality Characteristics | Lead Time (Days) |

|---|---|---|---|---|

Green Sand Casting | Uses wet sand and clay; easy to recycle; more defects | 1206 | Acceptable surface; more defects | 7 |

Dry Sand Casting | Baked sand molds; stronger for large parts | N/A | Smoother than green sand; good for heavy castings | N/A |

Shell Mold Sand Casting | Resin-coated sand; heated shell; complex shapes | 1460 | Very smooth surface; tight tolerances; fewer defects | 7 |

All three methods can make car and machine parts. Green sand and Shell Mold Sand Casting work well for making lots of parts fast.

Choosing the right casting method

Picking the best sand casting method depends on a few things. You need to think about part size, shape, surface look, and cost.

Green sand casting is good for simple shapes and big batches. It is the cheapest way.

Dry sand casting is best for large, heavy, or thick parts.

Shell Mold Sand Casting is great for parts with fine details, smooth surfaces, or exact sizes.

Factor | Description |

|---|---|

Casting size and complexity | Big or tricky parts may need strong molds like Shell Mold Sand Casting. |

Desired surface finish | Shell Mold Sand Casting gives the smoothest surface. |

Permeability | Green sand lets gases out, so there are fewer mistakes. |

Availability and cost | Green sand costs the least. Shell Mold Sand Casting costs more but makes better parts. |

Tip: If you need parts with exact shapes or fine details, Shell Mold Sand Casting is usually best. If you want lots of simple parts, green sand casting saves money.

Sand casting has three types: green sand, dry sand, and shell mold sand casting. Each type works in its own way. The table below shows how they are different:

Type of Sand | Characteristics | Advantages | Disadvantages |

|---|---|---|---|

Green Sand | Wet sand with clay; can be used again; soft mold that might break. | Simple and cheap to use. | Mold can break or move during casting. |

Dry Sand | Uses sodium silicate; gets hard fast with CO2; needs careful mixing. | Good for making holes inside parts. | Core can get stuck if mixed wrong. |

Shell Mold Sand | Mix of quartz sand and resin; makes a hard, smooth mold. | Makes fewer mistakes in castings. | Costs more and takes longer to make. |

Keming Machinery is known for Shell Mold Sand Casting. Their way makes smooth and exact parts for many jobs. To pick the best casting type, look at these things:

Criteria | Description |

|---|---|

Material Properties | Choose sand that fits the metal you use. |

Surface Finish | Think about how smooth and exact you want the part. |

Complexity and Size | See if the part is big or has a hard shape. |

Cooling Rate and Thermal Conductivity | Make sure the sand can handle heat well. |

Production Volume | Decide how many parts you need to make. |

Environmental Impact | Pick sand that is safe for nature. |

Tip: If you need parts with small details and exact sizes, Shell Mold Sand Casting is often the best choice.

FAQ

What is the main difference between green sand and shell mold sand casting?

Green sand casting uses wet sand mixed with clay. Shell mold sand casting uses sand with resin and heat. This makes a hard shell. Shell mold casting gives smoother parts. It also makes parts with more exact sizes.

Which industries use shell mold sand casting the most?

Car, airplane, and machine companies use shell mold sand casting a lot. These jobs need parts that fit well and look smooth. Keming Machinery helps many of these companies.

Can shell mold sand casting make complex parts?

Yes. Shell mold sand casting can make tricky shapes and thin walls. The process lets workers make detailed and exact parts.

What metals can Keming Machinery cast with the shell mold process?

Keming Machinery can cast iron, carbon steel, alloy steel, stainless steel, and aluminum alloys. Each metal is good for different uses.

Why do companies choose Keming Machinery for shell mold sand casting?

Companies pick Keming Machinery because they make good parts. They use new methods and test everything carefully. Their team gives custom help for each job.