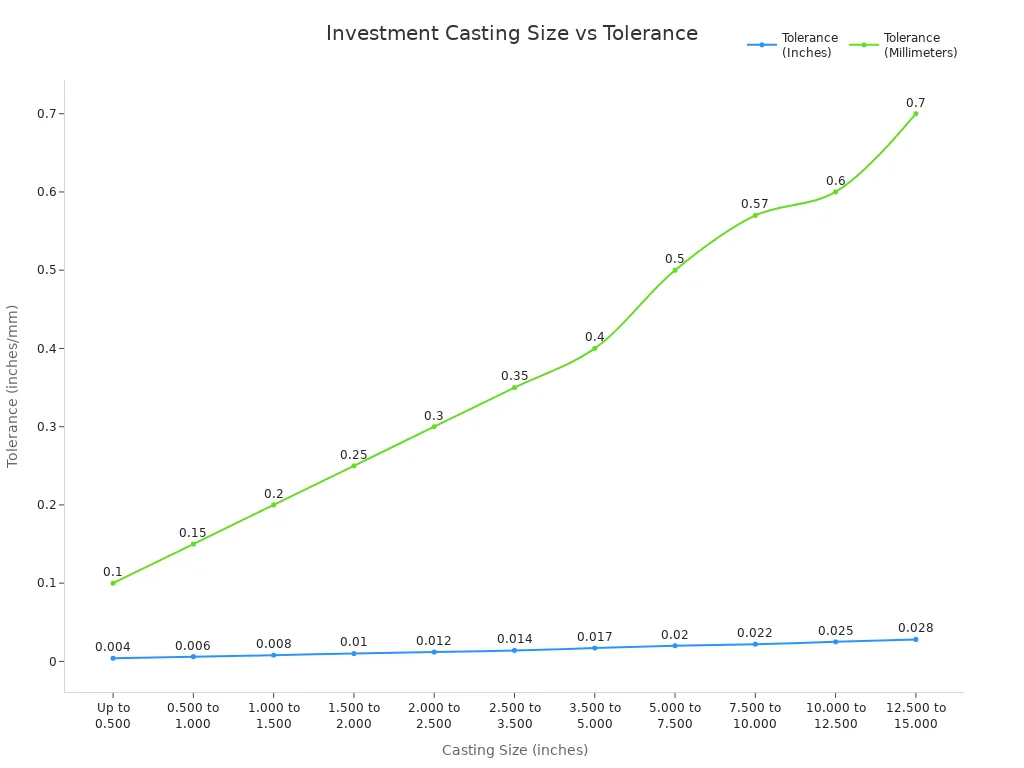

Investment casting processes achieve extremely high precision, with tolerances ranging from ±0.002 to ±0.010 inches (±0.05 to ±0.25 mm). The table below lists common precision casting tolerance ranges for parts of different sizes:

| Investment Casting Size | Tolerance (Inches) | Tolerance (Millimeters) |

|---|---|---|

| Up to 0.500 | ± .004″ | ± 0.10mm |

| 0.500 to 1.000″ | ± .006″ | ± 0.15mm |

| 1.000 to 1.500″ | ± .008″ | ± 0.20mm |

| 1.500 to 2.000″ | ± .010″ | ± 0.25mm |

| 2.000 to 2.500″ | ± .012″ | ± 0.30mm |

| 2.500 to 3.500″ | ± .014″ | ± 0.35mm |

| 3.500 to 5.000″ | ± .017″ | ± 0.40mm |

| 5.000 to 7.500″ | ± .020″ | ± 0.50mm |

| 7.500 to 10.000″ | ± .022″ | ± 0.57mm |

| 10.000 to 12.500″ | ± .025″ | ± 0.60mm |

| 12.500 to 15.000″ | ± .028″ | ± 0.70mm |

| Each additional inch add | ± .001″ | ± 0.025mm |

For engineers, designers, and parts buyers, precision is paramount. It helps them manufacture robust, durable, and meticulously detailed high-quality parts. KEMING employs advanced equipment and rigorous inspection processes to ensure that every part fully meets requirements.

Key Takeaways

- Investment casting offers extremely high precision, ranging from ±0.002 to ±0.010 inches, making it ideal for manufacturing delicate parts.

- The surface finish is exceptionally smooth, typically between 4 and 16 microinches, meaning minimal polishing is required, saving time and costs.

- This process enables the creation of complex shapes while maintaining tight tolerances, making it widely used in the aerospace and automotive industries.

- Quality inspection is paramount. KEMING employs specialized tools and methods to ensure every part meets stringent standards.

- Choosing investment casting enhances the strength and reliability of parts, enabling them to perform exceptionally well under harsh conditions.

Investment Casting Tolerances

Typical Investment Casting Tolerance Ranges

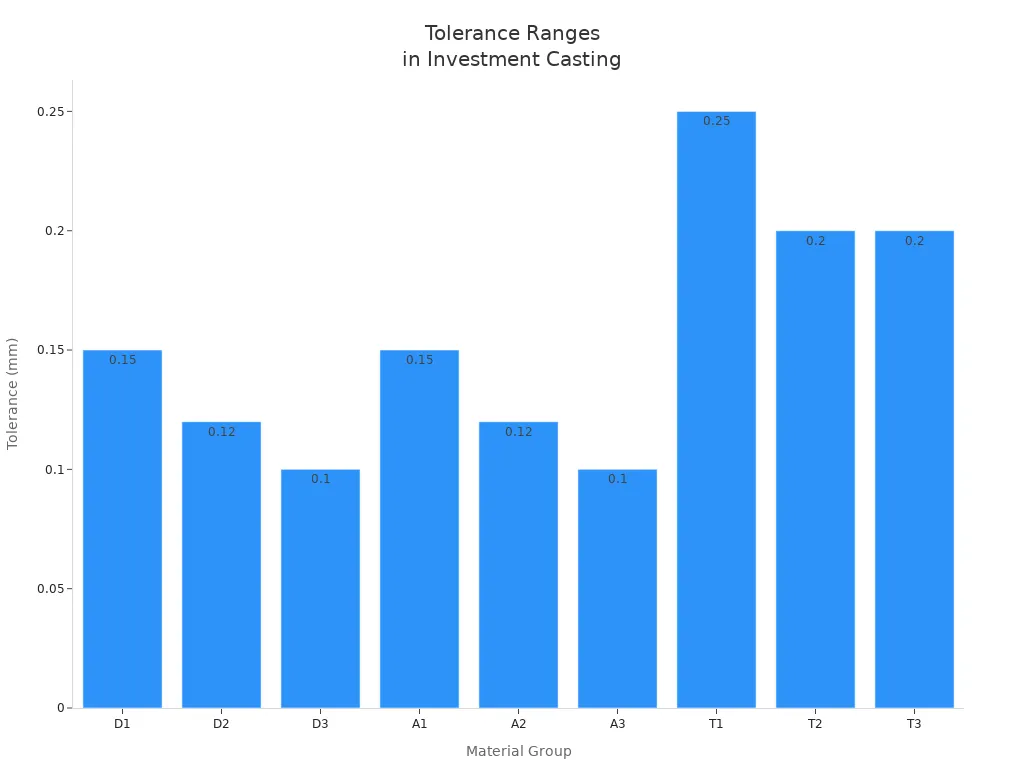

Investment casting produces parts with extremely small tolerances, suitable for a wide range of materials and sizes. Engineers favor this process because it achieves precision ranging from ±0.005 to ±0.015 inches. The following table lists the common tolerance ranges for different alloys and sizes:

| Material Group | Nominal Size Range (mm) | Tolerance (mm) |

|---|---|---|

| D1 | up to 6 | ±0.15 |

| D2 | up to 6 | ±0.12 |

| D3 | up to 6 | ±0.10 |

| A1 | up to 6 | ±0.15 |

| A2 | up to 6 | ±0.12 |

| A3 | up to 6 | ±0.10 |

| T1 | up to 6 | ±0.25 |

| T2 | up to 6 | ±0.20 |

| T3 | up to 6 | ±0.20 |

KEMING uses advanced equipment and rigorous testing processes to ensure that its products meet or exceed industry standards. Their team employs precise processes to guarantee that every casting meets requirements.

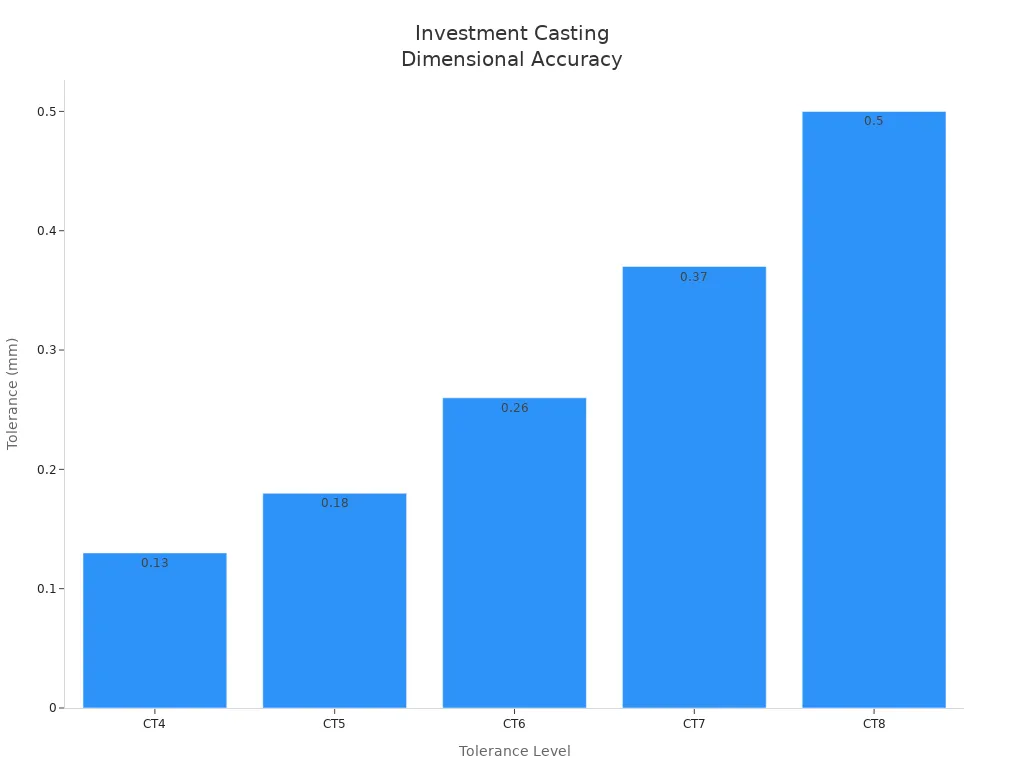

Investment Casting Dimensional Accuracy

Dimensional accuracy refers to the degree to which the dimensions and shape of a part closely approximate standard dimensions. In investment casting, precision depends on the measurement and control of each step. KEMING uses specialized tools such as coordinate measuring machines (CMMs) and 3D scanners to inspect parts. These tools help detect subtle errors before parts leave the factory.

The table below lists commonly used linear dimensional tolerances in investment casting:

| Tolerance Level | Linear Dimension Tolerance (mm) |

|---|---|

| CT4 | ±0.13 |

| CT5 | ±0.18 |

| CT6 | ±0.26 |

| CT7 | ±0.37 |

| CT8 | ±0.5 |

KEMING’s team uses process control and non-destructive testing like X-ray and CT scanning. These steps help make sure every part is correct for the customer.

Investment Casting Surface Finish

Surface finish refers to the smoothness of a part’s feel and appearance. Investment casting produces very smooth surfaces. The average surface roughness of most parts is between 4 and 16 microinches. This is significantly better than the surface finish of sand casting, which typically ranges from 250 to 500 microinches.

| Casting Method | Ra (µin) | Finish No. |

|---|---|---|

| Investment Casting | 4-16 | 8 |

| Sand Casting | 250-500 | N/A |

A smooth surface means less additional polishing or cutting is required. Parts manufactured using KEMING’s process can be used directly or require only minimal finishing. This saves customers time and money.

Tip: Good surface finish means less post-casting work, thus speeding up production.

Investment Casting Part Complexity

Investment casting can produce parts with complex shapes and fine details. Designers can add tight tolerances, internal spaces, and smooth surfaces. This process is ideal for complex parts that are difficult to manufacture using other methods.

- Engineers can design parts with complex internal spaces.

- This process allows for tight tolerances to minute details.

- Smooth surfaces typically require only minimal additional machining.

- KEMING casting can cast parts of various sizes, but it works best for small to medium-sized parts.

Designers should keep some rules in mind. Wall thickness should be at least 1.5–2.5 mm, depending on the alloy. Consistent wall thickness helps the metal fill the mold. Adding reinforcing ribs or gussets can enhance the strength of the part.

| Limitation/Challenge | Description |

|---|---|

| Size and Weight Constraints | Investment casting is best suited for small to medium-sized parts. Large or heavy parts are generally beyond the reach of this process. |

| Very Small Structures | Manufacturing tiny and delicate shapes can be difficult and may not achieve the desired results. |

| Uniform Wall Thickness | Maintaining consistent wall thickness is a major challenge in design. |

| Abrupt Transitions | Avoiding abrupt changes in the design is crucial for achieving good casting results. |

| Appropriate Draft Angle | Appropriate draft angles help in creating shells. |

KEMING experts help clients design parts to fully leverage the advantages of investment casting. Their team provides comprehensive support to clients throughout the process to achieve optimal results.

Factors Affecting Investment Casting Precision

Pattern and Mold Quality

Mold quality is crucial for the accuracy of investment casting. A high-quality wax model reveals minute details, helping to create properly sized parts. A robust ceramic mold maintains its shape during metal pouring, ensuring dimensional accuracy.

- Wax models should be smooth and undamaged.

- Ceramic molds must be strong enough to prevent cracking.

- Every step, from creating the wax model to immersing the ceramic mold, contributes to improved accuracy.

| Best Practice | Description |

|---|---|

| Design Simplicity | Simple shapes lower risks and make better molds. |

| Consistency in Wall Thickness | Same thickness stops warping and makes parts stronger. |

| Use of Draft Angles | Small angles help parts come out of molds easily. |

KEMING inspects molds and models using specialized tools before casting. Their team measures mold dimensions and applies release agent evenly. These steps help avoid errors and ensure that each part meets the standards.

Investment Casting Process Control

Process control determines the precision and repeatability of precision casting. Temperature and time must be precisely controlled. Inappropriate injection or pouring temperatures can lead to problems such as shrinkage. Appropriate pressure ensures the mold is completely filled.

| Factor | Influence on Accuracy and Repeatability |

|---|---|

| Injection Temperature | Factors Affecting Precision and Repeatability |

| Pouring Temperature | Controls metal flow and prevents problems. |

| Timing | Fills the mold evenly and stops mistakes. |

| Proper Pressure | Makes sure the mold is filled fully and evenly. |

Modern companies like KEMING utilize machines and intelligent technologies to assist production. These devices continuously monitor temperature, pressure, and time. Digital twins and 3D scanning technologies can inspect and predict results, thus ensuring the manufacturing precision of each part.

Investment Casting Design Complexity

The complexity of the part design also affects its precision. Simple designs with uniform wall thickness and reasonable draft angles are easier to cast. Core design prevents air trapping and aids mold filling. The number of gates and part weight affect the mold’s operating principle and cost.

| Design Aspect | Description |

|---|---|

| Draft Angles | Help take out wax patterns and stop mistakes. |

| Core Design | Stops air pockets and weak spots. |

| Weight and Size | Changes how much the mold can hold and the price. |

| Quantity of Gates | One gate makes the process steady and fast. |

| Wall Thickness | Even thickness makes parts more exact. |

KEMING’s engineers help customers choose the best design. They provide advice to help customers manufacture parts that are both precise and easy to machine. Their assistance ensures that every project meets high standards.

Tip: Simple designs and careful control of the process make investment casting work better.

Investment Casting Processes

Machining Adjustments

After casting, parts usually require further machining. Machining adjustments can make metal parts fit better. CNC machine tools can perform surface treatments such as cutting, drilling, or grinding. These steps help parts meet tighter tolerances and make surfaces smoother. Machining can create shapes that casting cannot achieve.

- Improved fit of castings.

- Helps parts meet tighter tolerance requirements.

- Smoother and more aesthetically pleasing surfaces.

- Manufacturing special shapes and details.

- Improved dimensional accuracy to design drawings.

- Enhanced surface strength and performance.

- Ensuring smooth operation and ease of assembly of parts.

Machining adjustments are crucial in many industries. The automotive, marine, and railroad industries require perfectly fitting parts that can function under pressure.

Quality Assurance

Quality assurance checks ensure that every part meets requirements. Multiple methods are used to inspect the precision of casting parts. Some tests check for surface cracks or micropores. Others inspect the interior of the part without cutting it open. Equipment such as coordinate measuring machines and 3D scanners are used to measure each part to check if it meets design requirements.

| Method | Purpose |

|---|---|

| Visual and Dimensional Inspections | Inspect parts for compliance using specialized equipment. |

| Ultrasonic Testing | Check the internal strength of parts. |

| Non-Destructive Testing (NDT) | Use X-rays and CT scans to find hidden holes or problems. |

| Penetration Testing | Find surface microcracks. |

| Mechanical Testing | Test the strength and toughness of the material. |

| Hardness Testing | Checks if the part can resist wear and bending. |

Quality assurance begins before casting and continues after casting. The team inspects materials and design to prevent problems from occurring. During casting, they monitor the entire process and quickly correct errors. After casting, they inspect and test each part to ensure it meets requirements. These steps help provide customers with robust and precise parts suitable for a wide range of projects.

Note: Fine machining and rigorous quality inspection are key to manufacturing high-quality investment casting parts.

Investment Casting vs. Other Methods

Sand Casting Comparison

Sand casting and investment casting are two methods for manufacturing metal parts. Each method has its advantages and disadvantages. The table below shows their differences in precision and surface finish:

| Casting Method | Typical Tolerance | Surface Finish (Ra, µm) |

|---|---|---|

| Sand Casting | ±1.5–3.0 mm | 6.3–25 |

| Investment (Lost-Wax) | ±0.1–0.5 mm | 1.6–6.3 |

Sand-cast parts have a rougher surface and lower precision. These parts typically require more machining after casting. Investment-cast parts have a smoother surface and higher precision. Designers can use it to manufacture thin-walled parts and complex shapes.

The table below lists the advantages and disadvantages of each method:

| Aspect | Investment Casting | Sand Casting |

|---|---|---|

| Precision | Very tight tolerances (up to .003″) | Shapes are close but not exact |

| Surface Finish | Smooth finish, about 125 micro | Rougher finish |

| Cost | Costs more to start and make | Cheaper to make |

| Size Limitations | Best for small, detailed parts | Can make big parts (up to 6,000 lbs) |

| Production Cycle | Takes longer because it is complex | Faster to make |

| Design Capabilities | Can make hard shapes | Simple shapes only |

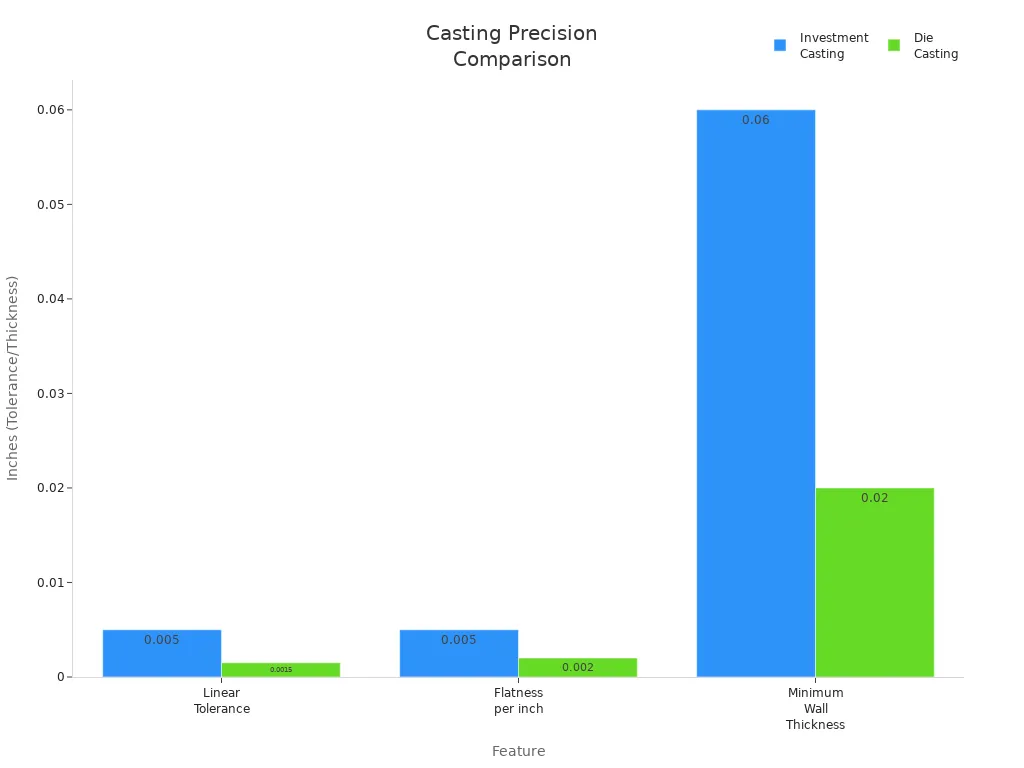

Die Casting Comparison

Die casting uses high-strength steel molds to quickly manufacture large quantities of parts. It is suitable for mass production of identical parts. This method allows for very small tolerances and extremely thin wall thicknesses. The table below compares the accuracy and wall thickness for each method:

| Feature Tolerance | Investment Casting | Die Casting |

|---|---|---|

| Linear Tolerance (Typical) | ±0.005 in/in | ±0.0015 in/in |

| Flatness (per inch) | 0.005 inches | 0.002 inches |

| Minimum Wall Thickness | ~0.060″ (1.5 mm) | ~0.020″ (0.5 mm) |

Die casting produces parts that are almost always identical. Investment casting can produce more refined and complex shapes.

Application Implications

Precision casting is best suited for manufacturing parts with complex shapes and high tolerance requirements. It is commonly used in applications demanding extremely high precision, such as aerospace, automotive, medical devices, and energy machinery. The table below lists the best application areas for precision casting:

| Industry | Description |

|---|---|

| Aerospace | Light and tricky parts |

| Automotive | Exact parts for safety and performance |

| Medical Equipment | Parts that must be just right |

| Industrial Machinery | Hard shapes for machines |

| Energy | Exact parts for turbines |

| Electric Vehicle | Battery and motor parts |

| Food Processing | Good parts for food machines |

| Military | Strong and reliable parts |

| Mining | Tough and exact equipment |

| Nautical | Tricky parts for boats |

| Paper Manufacturing | Exact parts for paper machines |

| Water Desalination | Good parts for cleaning water |

Tip: Precision casting is recommended for small, complex parts requiring smooth surfaces and high tolerances. It helps engineers and designers create robust and durable products that can withstand various harsh working environments.

Parts manufactured using the precision casting process have excellent fit and a smooth, aesthetically pleasing surface. This manufacturing method is particularly suitable for complex-shaped parts and is widely used across numerous industries. Choosing the optimal casting method helps produce robust and durable parts, extending their lifespan. KEMING uses advanced equipment and rigorously inspects each part to ensure that every project meets high standards.

| Aspect | Benefit |

|---|---|

| Precision | Tight tolerances for exact parts |

| Surface Finish | Smooth surfaces with little extra work |

| Quality Control | Careful checks for safety and strength |

- KEMING’s team plans and checks each part to get great results.

FAQ

What are the typical tolerances for investment casting?

Most investment casting parts are very precise. Their tolerances are typically between ±0.005 inches and ±0.015 inches. KEMING often produces parts with even higher precision. These parts are used in many different industries.

What is the surface finish of investment casting?

Investment casting produces very smooth surfaces. The surface roughness is typically between 4 and 16 microinches (Ra). This smooth surface means that little or no additional polishing is needed.

Can investment casting create complex shapes?

Yes, investment casting can create complex shapes. Engineers can design parts with minute details, thin walls, and internal spaces. This process is suitable for shapes that cannot be produced by other casting methods.

Which industries most commonly use investment casting?

Aerospace, automotive, medical, marine, and industrial machinery companies use investment casting extensively. They require parts with high precision, high strength, and excellent performance.

Does investment casting require post-cast machining?

Some parts require additional machining after casting. Additional machining helps achieve tighter tolerances or special shapes. Coming uses advanced CNC machine tools to finish parts when necessary.