A kiln is often needed for lost wax casting. It gets very hot, almost 1700 degrees Fahrenheit. This heat melts the wax and makes the mold hard. The process also produces smoke and vapors, so you need good airflow. Some people use steamers to remove the wax. However, kilns ensure that the mold is strong for tough parts like agricultural castings and automotive castings. Using the right tools helps prevent mistakes and delivers excellent results.

Key Takeaways

A kiln is very important for lost wax casting. It melts the wax and makes the mold stronger. This helps you get good castings every time.

Keeping the right temperature in a kiln stops mold problems. This helps you get the same good results each time you cast.

If you cast without a kiln, it can be unsafe. You might also get bad pieces. Always stay safe and use the right tools.

If buying a kiln costs too much, try sharing one. You can also use a kiln at a community place. This helps you control heat better and stay safe.

Buying a kiln costs more at first, but it saves time later. It also helps you make fewer mistakes over time.

Why a kiln matters in lost wax casting

Wax burnout and mold preparation

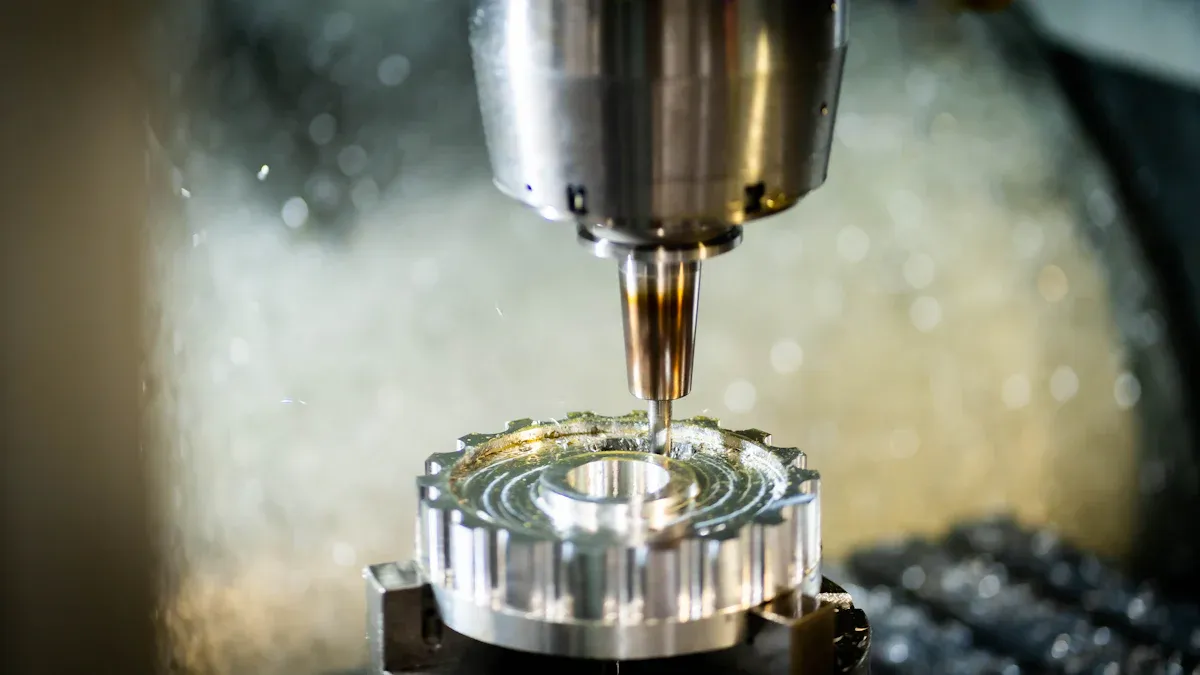

A kiln plays a key role in lost wax casting. It removes the wax from the mold and prepares the mold for metal. The process starts with heating the mold to melt and drain the wax. Research shows that the timing of wax burnout affects the final casting. If the burnout happens too quickly, the mold can crack. If it takes too long, the casting may shrink and lose detail. Proper burnout timing helps keep the mold strong and the casting accurate. The kiln also dries out any moisture in the mold. This step prevents steam from forming when hot metal is poured in. Without a kiln, the mold may not reach the right temperature, and the casting can fail.

Temperature control for casting success

Precise temperature control is important for lost wax casting. The kiln heats the mold in several steps. Each step uses a different temperature to help remove wax and harden the mold. The table below shows the main phases and their temperature ranges:

Phase | Temperature Range |

|---|---|

Preheat | 300ºF |

Wax Drain | Hold for 1 hour |

Temperature Increase Rate | 300º/400ºF per hour |

Peak Burnout | 1350ºF |

Hold Time at Peak | 2 hours or more |

Modern kilns use advanced controls. Features like TAP controllers and solid-state relays help keep the temperature steady. Some kilns even allow remote monitoring with a mobile app. These tools make sure the mold heats evenly and safely. Good temperature control leads to better casting results and fewer mistakes.

Safety and consistency in the process

A kiln makes lost wax casting safer and more reliable. The high heat removes all the wax and strengthens the mold. This process creates a clean, hollow space for the metal. The table below explains how each step helps:

Step | Description |

|---|---|

Wax Removal | The wax melts and leaves a precise cavity in the mold. |

Mold Strength | The heat makes the ceramic mold strong enough to hold molten metal. |

Quality Impact | Proper wax removal and mold preparation improve the quality of the final casting. |

Using a kiln also means each casting turns out the same. This consistency is important for industries like automotive and agriculture. Companies like KEMING use kilns and strict quality checks to make sure every part meets high standards. Their experience shows how professional kiln use leads to strong, accurate castings.

Challenges of casting without a kiln

Incomplete wax removal issues

If you do not use a kiln, wax can stay in the mold. The mold might not get hot enough to melt all the wax. Leftover wax blocks the space where metal should go. This can make the final piece have missing parts or weak areas. Artists and hobbyists see that leftover wax causes bumpy surfaces and bad details. Lost wax casting needs all the wax gone for good results. Without a kiln, the mold is not ready for pouring metal.

Mold defects and casting failures

Not using a kiln can cause many mold problems. Some common issues are:

Porosity, which means tiny holes form inside the casting.

Gas porosities, which happen when gas gets stuck in the metal.

Shrinkage porosities, which show up if there is not enough melted metal as it cools.

Dendritic crystal porosities, which come from low temperatures when the metal hardens.

Gas entrapment, which happens if air gets trapped while pouring.

These problems make the casting weak and not safe to use. Many artists find cracks, holes, and rough spots in their work. Without enough heat, the mold cannot stay strong or keep its shape. Castings can break easily or not meet the needed quality.

Safety risks and unpredictable results

Casting without a kiln can be very dangerous. Molten metal gets as hot as 800°C. Handling it without the right tools can burn you badly. If water or moisture is in the mold or tools, it can explode. Fast steam can splash hot metal and hurt people. Wet tools make these dangers worse. People need special clothes and training to stay safe. Bad airflow lets fumes build up, which can make you sick. Results are also hard to predict. Castings may not look right, wasting time and supplies.

Alternatives to a traditional kiln

Using home ovens or makeshift furnaces

Some people use home ovens or build simple furnaces. These choices are easy to set up. But they have big problems. The table below lists some issues:

Limitation | Description |

|---|---|

Carbon Contamination | Home setups can add extra carbon to the casting. |

Melting Capacity | Home ovens cannot reach the high heat needed for casting. |

Safety Risks | Handling hot metal without good tools can hurt you. |

Home ovens may not get hot enough to melt all the wax. They also may not make the mold hard enough. Simple furnaces can be dangerous if they do not have safety parts. These ways might work for small and easy projects. But they are not good for big or detailed castings.

Torch burnout and its limitations

Some people use a torch to melt wax out of molds. This can remove wax with high heat. But it has problems. The mold may not heat evenly. Some wax can stay inside. Kilns are made to let air flow well. This helps get rid of carbon. Torches do not always do this. Steam dewaxing can melt most wax before using a torch. But it does not work for every kind of wax. Torch burnout is best for small molds or fast jobs. It cannot do as well as a kiln.

Accessing community or shared kilns

Many people look for kilns they can share. Makerspaces, art centers, and schools sometimes have kilns. People share tips online about using torches or making simple setups. Some use a flower pot lined with foil. These ideas help more people try lost wax casting. Shared kilns give better heat control and safety than ovens or torches. They are good for people who do not want to buy a kiln. You can check local places or online groups to find shared kilns.

Tip: Shared kilns have rules for everyone. Always ask about safety and how to sign up before you start your project.

Practical tips for lost wax casting beginners

Sourcing an affordable kiln

Many beginners want a kiln that does not cost too much. There are different entry-level kilns for lost wax casting. Each one has its own price and features.

Some people buy used kilns or share with others at makerspaces. Looking at online groups and forums can help you find good deals.

Safety tips for high-heat equipment

Working with hot tools means you must be careful. Always wear gloves that protect from heat, safety glasses, and closed shoes. Make sure your workspace has good airflow to clear out fumes. Never pour metal near water or anything wet. Keep a fire extinguisher close by. Read the kiln manual and follow all safety rules to keep everyone safe.

Tip: Wait until the kiln is fully cool before opening it. Molds stay hot and can burn you even after turning off the power.

Budgeting for casting projects

Starting lost wax casting costs money for tools and supplies. A simple setup can cost less than $2,000. Kilns can cost from $1,796.40 up to $4,680.00. You can save money by:

Sending your work to a professional casting service

Using cheaper metals like bronze or brass

Making just one or two pieces at first

Using tools you already have for carving wax

Not using gold or other expensive metals

Strategy | Description |

|---|---|

Outsourcing Casting | Use professional casting houses to avoid buying expensive equipment |

Start with Cheaper Metals | Begin with bronze or brass to lower costs |

Start Small | Make 1-2 pieces to learn before scaling up |

Use Existing Tools | Carve wax with tools already owned |

Leveraging KEMING’s investment casting services

KEMING helps beginners by offering many useful services. Their investment casting makes parts with exact shapes and fine details. They use materials wisely, so there is less waste and lower costs. KEMING can make small, medium, or large orders. They work with many metals, like carbon steel and stainless steel.

Advantage | Description |

|---|---|

Precision and Complex Shapes | Makes parts with exact shapes and fine details |

Material Efficiency | Uses materials smartly, reducing waste and costs |

Versatility for Production Volumes | Handles small, medium, and large orders |

Wide Range of Metals | Works with carbon steel, stainless steel, and more |

KEMING follows strict rules for quality. They use tests like hardness testing, X-ray testing, and magnetic particle inspection. These tests make sure every casting is high quality. The company meets ISO 9001, AS9100, and other world standards. Beginners can trust KEMING to give good results for their lost wax casting projects.

Choosing the right approach for lost wax casting

Weighing kiln investment vs. alternatives

People who want to try lost wax casting often look at the price of a kiln. They also think about using other ways. Many artists use beeswax and clay because it is an old method. This works for jewelry and small art. Modern investment casting uses machines and special materials. It makes parts with thin walls and exact shapes. This process lets you make more designs and get smoother finishes. Kilns cost more at first, but they save money later. You do not need as much extra work on the parts. Here are some things to think about:

Simple ways work for art, but factories need exact tools.

Kilns give better control and make higher quality pieces.

Home ovens or torches can be used for small jobs, but they cause more mistakes.

Long-term considerations for hobbyists

Hobbyists should think about quality and cost over time. Using good materials like Bluecast resins helps make better castings. These materials cost more, but they stop mistakes and save time. Cheaper ways can give mixed results and take longer. Wax master models almost always work, but resin models fail more. The table below shows the difference:

Method | Success Rate | Production Time | Cost |

|---|---|---|---|

Wax Master | 99% | Short | Moderate |

Resin Model | <50% | Long | High |

Tip: Buying better tools and materials means fewer mistakes and better castings.

When to partner with professionals like KEMING

Some projects need help from experts. KEMING offers casting services for people who want good results. They use modern machines and check quality carefully. Their team works with many metals and can do small or big orders. Working with pros saves time and makes sure each part is made well. People who do not want to buy costly tools or need tricky parts often pick professional casting.

Note: Working with experts like KEMING helps hobbyists and businesses get strong, accurate castings without the risk of failed projects.

A kiln helps make metal parts turn out the best. If you do not use a kiln, molds can be weak and it can be unsafe. There are other ways to cast, but they can lower quality and safety. People need to think about what they want, how to stay safe, and how much money they have before they start. KEMING can help with expert advice and good casting services for people who want strong and exact parts.

FAQ

What does a kiln do in lost wax casting?

A kiln gets very hot to melt the wax out. It also makes the shell hard and strong. This helps the mold hold the hot metal safely. The kiln dries out water in the mold. This stops steam from causing dangerous blasts.

Can someone use a regular oven instead of a kiln?

Most ovens at home do not get hot enough. They cannot melt all the wax or make the mold hard. This can make the casting weak or not work at all.

Is lost wax casting safe for beginners?

Lost wax casting is safe if you follow the rules. Beginners should wear gloves, goggles, and closed shoes. Work in a place with fresh air. Keep water away from hot metal. Young people need an adult to help them.

What metals can KEMING cast with lost wax casting?

Metal Type | Example Uses |

|---|---|

Carbon Steel | Engine parts |

Stainless Steel | Marine hardware |

Iron | Agricultural tools |

Aluminum Alloy | Lightweight parts |

KEMING uses many metals for different jobs.