Choosing between investment casting and forging depends on your project. Engineers look at things like shape, size, and surface finish. Investment casting is good for parts with tricky shapes or inside spaces. Forging makes parts that are very strong and have smooth surfaces. Cost matters too, since casting needs less money for tools and wastes less material. Big parts are often made by casting. Forging is better for small or medium parts. Designers pick the method that fits the material, how many parts they need, and how strong the parts must be.

Understanding the Investment Casting Process and Its Key Applications

Key Advantages of the Investment Casting Process

Investment casting, also called lost-wax casting, is great for making metal parts with hard shapes and small details. The process has several steps:

- Wax patterns are made to match the part’s shape.

- A ceramic shell is built to make a strong mold.

- The wax is melted out, leaving a hollow mold.

- Hot metal is poured in to form the part.

- The ceramic shell is broken off to get the part.

- Wax patterns and assembly are checked for accuracy.

- Extra material is removed and the surface is smoothed.

This method gives very accurate and precise parts. It can make castings with tight tolerances. Investment casting gives a smoother finish than other casting methods. The smooth wax and ceramic shell help show small details on the final part. This means less extra work is needed. Many alloys can be used, even for important jobs.

Tip: Investment casting works well for parts with tricky shapes and smooth surfaces.

Ideal Applications and Industries Where Investment Casting Excels

Investment casting is used in many fields that need careful work and good quality. The table below lists some common uses:

| Industry | Typical Applications |

|---|---|

| Aerospace | Turbine blades, engine parts, brackets, control units |

| Automotive | Gears, transmission parts, brakes, housings (casting in the automotive industry) |

| Medical | Implants, surgical instruments, prosthetic components |

| Industrial Machinery | Pump impellers, valve bodies with complex internals |

| Defense | Weapon components, bomb racks, missiles |

| Marine | Pumps, deck hardware, engine components |

| Dairy and Food | Dishwashers, meat slicers, food processing equipment |

Aerospace and medical companies use investment casting for turbine blades, implants, and other parts that need to be exact and have special shapes. These fields trust this process for important parts that must work well.

Limitations and Potential Drawbacks of the Investment Casting Process

Even though investment casting has many good points, it also has some limits. Most places in the U.S. can only make parts up to about 40 inches or 20 pounds, but some can do bigger. The process works with many alloys, but some, like brass, need extra care because of problems like zinc loss. Investment casting costs more and takes longer than some other ways. There are many steps, so mistakes can happen and costs can go up. Making tools for hard parts can cost a lot, especially if you only need a few. After casting, more work like machining and checking the parts can add to the price.

Note: Think about size, material, and how many parts you need before picking investment casting.

Exploring the Forging Process and Its Key Advantages and Applications

Advantages and Benefits of the Forging Process

Forging uses heat and pressure to shape metal. This makes parts stronger and tougher. The steps in forging are simple:

- Pick metal for its strength and how it bends.

- Heat the metal until it is soft.

- Hammer or press the metal into the right shape. This step makes the grains line up and adds toughness.

- Cut off extra metal and smooth the part.

- Test and check the part for quality.

Forged parts have grains that are tight and straight. These grains help the metal stay strong and last longer. Forged parts do not have holes or empty spaces. They can handle hits better than cast parts. The process also stops problems like shrinking and dirt. Many companies use forging for parts that must be strong and work well.

Tip: Forging makes parts that do not get tired and work under stress.

Typical Applications and Industries Where Forging Delivers the Best Results

Many companies need forging for important parts. The table below shows where forging is used and lists common forged items:

| Industry | Reliance on Forging | Common Forged Products and Components |

|---|---|---|

| Automotive | Uses forging for safety and good performance | Crankshafts, connecting rods, gears, battery housings, chassis |

| Aerospace | Needs forging for strong parts | Turbine blades, airframe parts, light parts |

| Energy | Uses forging in oil, gas, and green power | Wind flanges, gas turbine parts, nuclear equipment |

| Construction | Needs big forged parts | Structure parts, machine parts |

| Machine Manufacturing | Uses forging for strong machines | Many machine parts |

| Defense | Needs special materials | Special forged parts |

Forging in oil and gas makes valves, fittings, and connectors. These parts can handle high pressure and heat. Car companies use forging for gears, axles, and suspension parts. These parts must be tough and last a long time.

Limitations and Potential Challenges of the Forging Process

Forging has some problems. It is hard to make shapes that are tricky. The process works best for simple shapes. Big parts need special machines, so size can be a problem. Not every metal works well with forging. Some alloys do not like heat and pressure. Forged parts often need more cutting to get the right size and smoothness. This takes more time and costs more money. Tools wear out fast because of high pressure, so expenses go up. Making hard parts may need many dies and steps. This can cause mistakes and waste metal. Old forging methods have many steps, so they are slower and cost more than other ways.

Difference Between Casting and Forging

When picking between investment casting and forging, engineers think about many things. The way casting and forging are done changes how strong, exact, and costly the parts are. It also changes what metals can be used and how many parts can be made. The next parts talk about these differences.

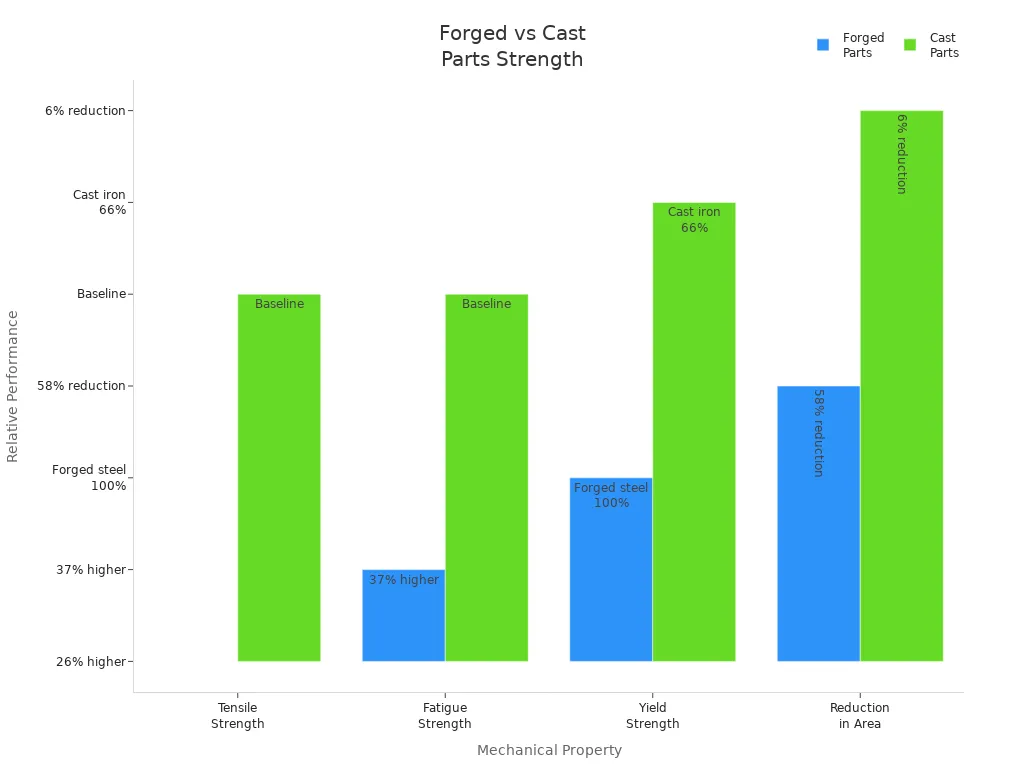

Strength

Forging makes parts that are stronger than investment casting. When metal is forged, its grains line up better. This makes the part tougher and more solid. The grain flow helps the part take more hits and stress. Forged parts have fewer weak spots like holes or empty spaces.

- Forged parts are 26% stronger in pulling tests.

- They are 37% better at handling repeated stress.

- Forged parts can stretch more before breaking.

- Forging gets rid of problems that make cast parts weak.

| Property | Forged Parts | Cast Parts (including Investment Cast) |

|---|---|---|

| Tensile Strength | 26% higher | Baseline |

| Fatigue Strength | 37% higher | Baseline |

| Yield Strength (Cast Iron vs Forged Steel) | Cast iron at 66% of forged steel | N/A |

| Reduction in Area at Failure | 58% reduction | 6% reduction |

Forged aluminum and steel are used when parts need to be very strong. Investment casting lets you make more shapes but is not as strong as forging.

Precision

Precision is another big difference between casting and forging. Investment casting can make parts with very exact sizes. It uses wax and ceramic molds to copy small details. Forging uses pressure to shape metal. This works for simple shapes but not for tiny details.

- Investment casting can be exact to ±0.1 mm to ±0.3 mm.

- Forging is good for simple shapes but not for tricky ones.

- Investment casting gives smoother surfaces with less extra work.

- Forged parts need more cutting or polishing to look nice.

| Process | Dimensional Tolerance Range | Notes |

|---|---|---|

| Investment Casting | ±0.1 mm to ±0.3 mm per linear inch | Tighter tolerances, suitable for intricate and small parts |

| Forging (Close Die) | Good accuracy but less tight than casting | Best for less complex shapes |

Pick investment casting if you need exact sizes and smooth finishes. Forging is better if you care more about strength than small details.

Cost

Cost is a big thing to think about when choosing casting or forging. Investment casting is often cheaper for small batches or test parts. This is because it uses softer molds that are easy and quick to make. Forging needs hard steel dies that cost more and take longer.

- Investment casting costs less for tools, so it is good for custom parts.

- Forging tools cost more and take longer to make.

- Forging dies wear out faster, so you pay more over time.

- For big batches, forging can be cheaper because it is faster.

Investment casting saves money for small runs and tricky shapes. Forging is better for making lots of simple parts, even if it costs more at first.

Material Options

Both investment casting and forging can use many metals and alloys. This lets engineers pick the best metal for the job.

- Investment casting works with stainless steels, brass, bronze, nickel, cobalt, aluminum, and special alloys.

- Forging also works with many alloys, especially strong steels.

Investment casting makes parts with no inside stress or lines. Forging can add some stress but makes the metal very even. Both ways are good for many metals, but investment casting is best for special alloys.

Production Volume

How many parts you need changes which method is best. Casting, including investment casting, is great for making lots of parts. Once you have a mold, you can make many parts fast.

| Aspect | Forging | Casting (including Investment Casting) |

|---|---|---|

| Production Speed | Faster production speed | Slower production speed compared to forging |

| Design Flexibility | Limited design flexibility | Greater design flexibility and ability to produce complex shapes |

| Scalability for Large-Scale Manufacturing | Not explicitly scalable for very high volumes | Highly scalable due to mold reuse and efficient high-volume output |

Investment casting gets cheaper as you make more parts. The mold cost is spread out over many pieces. This makes it good for mass production. Forging is faster but not as good for tricky shapes or huge numbers.

Note: The best choice depends on what your project needs. Use investment casting for exact, smooth, and complex parts. Use forging for strong, tough parts and lots of simple shapes.

Decision Checklist: Investment Casting vs Forging

Key Project Requirements to Consider Before Choosing Investment Casting or Forging

Picking the right process starts with knowing what your project needs. Engineers should look at the part’s shape and size. They also need to see how much detail the part needs. The material and how strong the part must be are important too. Some projects need a smooth surface or exact sizes. Others need parts that can take heavy weight or stress.

Tip: Always make sure the process fits your time and money plan.

A simple checklist helps you match your project to the best way:

- Look at the part’s shape and how hard it is to make.

- Check what material you need for the part.

- Decide if you need the part to be strong or have small details.

- See if the process can make enough parts for your needs.

- Compare the prices for investment casting and forging.

- Make sure the shop has the right tools and skilled people.

- Check for good quality and experience in the industry.

Step-by-Step Guide to Selecting the Right Process for Your Project

Engineers can use these steps to pick between investment casting and forging:

- Write down what the part must do and how it should work.

- Look at the design to see if it is tricky or needs to be exact.

- Pick the material for strength, bending, and how it will be used.

- Guess how many parts you need to find the cheaper way.

- Compare how smooth and exact the part must be.

- Check the costs for tools, workers, and finishing.

- Make sure the shop can finish on time and meet quality rules.

A table can help you see the differences:

| Factor | Investment Casting | Forging |

|---|---|---|

| Best for | Complex, precise shapes | High strength, durability |

| Surface Finish | Very smooth | Needs extra finishing |

| Production Volume | Small to large batches | Medium to large batches |

| Costs | Lower for small runs | Lower for high volumes |

| Material Options | Wide range | Mostly metals/alloys |

By using these steps, teams can pick the best way. This helps keep the project on budget and meets all needs.

Picking the best process depends on what your project needs most. Investment casting is good for parts with hard shapes and exact sizes. It also works for many sizes and materials. Forging is best when you need strong parts that last a long time. The checklist and table help you choose the right way. For tough projects, it is smart to ask a manufacturing expert for help.

FAQ

What is the main difference between investment casting and forging?

Investment casting makes metal parts by pouring into a mold. Forging shapes metal using heat and pressure. Casting is good for making tricky shapes. Forging makes parts that are stronger.

Which process gives a better surface finish?

Investment casting gives smoother surfaces most of the time. Wax and ceramic molds help show small details. Forged parts need extra work to look smooth.

Can both processes use the same metals?

Both ways work with lots of metals. Investment casting uses stainless steel, aluminum, and special alloys. Forging works best with strong metals like steel and aluminum.

When should a project use forging instead of casting?

Use forging when you need parts that are very strong. Forged parts are used in cars, planes, and big machines.

Is investment casting more expensive than forging?

- Investment casting costs less for small or tricky parts.

- Forging is cheaper for lots of simple parts.

- The price can change because of tools and finishing.