You will see stainless steel alloys, aluminum alloys, and carbon or low-alloy steels as top choices for Investment Casting Services in 2025. Picking the right material changes how strong, light, and dependable each part is. KEMING has over 20 years of experience in Investment Casting Services, helping you choose from more than 100 materials.

Picking the right material helps make new and better castings.

| Study Title | Key Findings |

|---|---|

| Investment Casting | Alloy choice changes how parts handle heat and stress. |

| Assessment of 17-4 PH Steel | Recycled steel works well for turbine blades. |

| Grain Refining in Aluminum | Makes parts thicker and more even. |

| Market Forecast | Lighter alloys help save fuel. |

Key Takeaways

- Picking the right material for investment casting is very important. It changes how strong, heavy, and long-lasting the parts are.

- Stainless steel alloys are liked because they do not rust and are strong. They work well for tough jobs like medical tools and turbine blades.

- Aluminum alloys are light but still strong and do not rust. They are great for cars and airplanes.

- Carbon and low-alloy steels are cheaper choices for tough jobs. They are strong and last long, so they fit machines and vehicles.

- KEMING uses skill and new technology to give great investment casting services. They help customers pick the best materials for what they need.

Materials Used in Investment Casting

There are many investment casting materials today. The most used ones are stainless steel alloys, aluminum alloys, and carbon or low-alloy steels. These materials decide how strong, light, and tough your parts are. Picking the right material makes your parts work better and last longer. KEMING uses new technology and lots of experience to help you pick the best material.

It is very important to choose the right material. Each one has special benefits for different jobs. You must match the material to the job to get the best results.

Steel alloys are the most popular because they work well and cost less. Aluminum alloys are getting more popular since they are light and strong. There are also titanium, nickel, and cobalt alloys, but most people still use stainless steel, aluminum, and carbon steels.

| Trend | Description |

|---|---|

| Advancements in Materials Science | New ideas make better casting steels and green materials. |

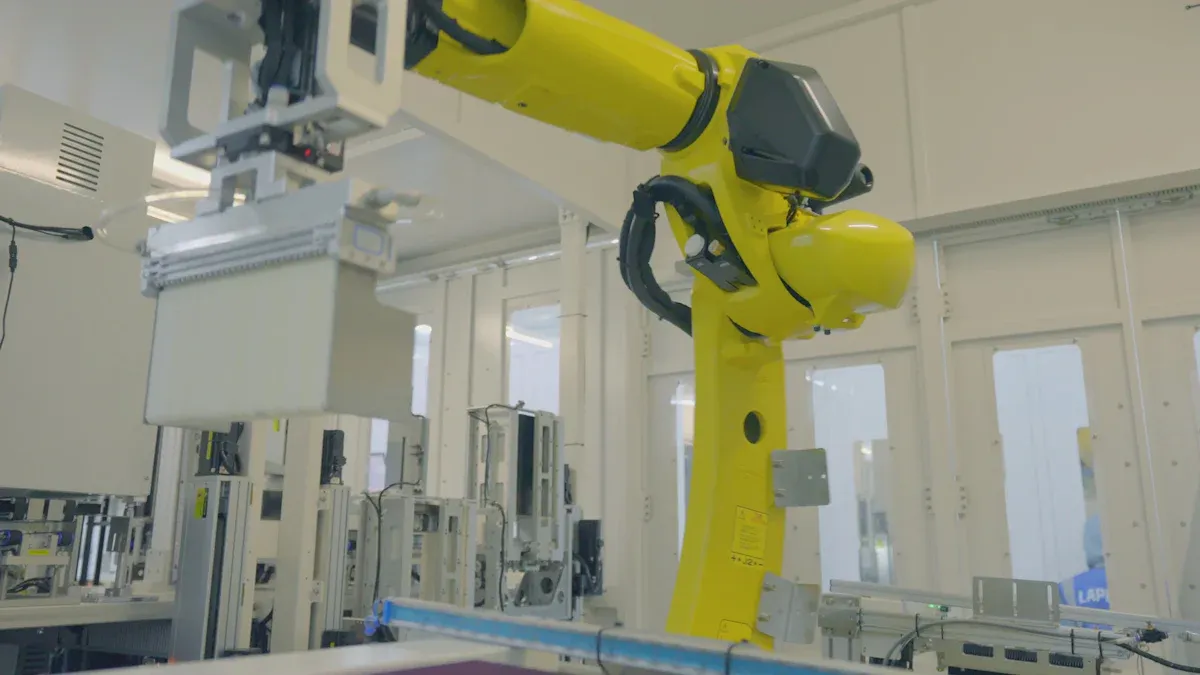

| Increased Automation | Machines help make casting faster and more exact. |

| Sustainable Manufacturing Practices | Using recycled materials and green methods helps the planet. |

| Demand for High-Strength Alloys | People want stronger materials that do not cost too much. |

| Growth in Precision Casting | More companies need very exact parts. |

Stainless Steel Alloys

Stainless steel alloys are a top pick for investment casting. Many industries use them because they do not rust and are very strong. Chromium in stainless steel makes a shield that stops rust and damage. You get smooth parts that need little extra work.

| Property/Advantage | Description |

|---|---|

| Corrosion Resistance | Chromium keeps stainless steel from rusting. |

| Strength & Durability | It stays strong and tough, even when it is hot. |

| Precision & Surface Finish | You can make detailed parts with little finishing. |

| Material Versatility | Many types fit different jobs. |

| Excellent Repeatability | You get the same results every time. |

- Stainless steel is used in:

- Turbine blades in airplanes

- Medical tools and implants

- Car engine parts

- Turbines and valves for energy

Stainless steel is liked because it fights rust, wear, and heat. These things matter for tough jobs. You get parts you can trust for a long time.

Aluminum Alloys

Aluminum alloys are another great choice for investment casting. They are light, so parts are easy to move. Aluminum is strong for its weight, so your parts are not heavy but still tough. It also does not rust easily, so parts last longer.

| Benefits of Aluminum Alloys in Investment Casting |

|---|

| Saves money |

| Strong but light |

| Lasts a long time |

| Does not rust |

- Aluminum alloys help you:

- Make light parts for planes and cars

- Get strong parts for important jobs

- Use less energy and save on materials

- Make detailed shapes with little extra work

New aluminum alloys are even stronger and resist rust better. This helps in jobs where parts face hard conditions. Casting now makes parts more exact and smoother. Using recycled aluminum is good for the planet.

Carbon and Low-Alloy Steels

Carbon and low-alloy steels are strong, tough, and not too expensive. You use them when you need parts that can take a lot of weight and wear. Carbon steel is easy to shape and costs less. Low-alloy steels are even stronger for hard jobs.

| Attribute | Description |

|---|---|

| Strength | These steels are strong for hard work. |

| Durability | They last a long time. |

| Cost-effectiveness | You save money and get good parts. |

- Carbon steel is used in:

- Army vehicles on land

- Oil and gas machines

- Conveyor belts

- Low-alloy steel is found in:

- Farm machines

- Defense jobs

- Oil and gas parts

- Army vehicles

- Construction machines

You pick these steels for their strength and toughness. Alloys like AISI 4140 and AISI 8620 are used in tools and big parts. These materials help you make parts that last and work well in many jobs.

KEMING Investment Casting Services

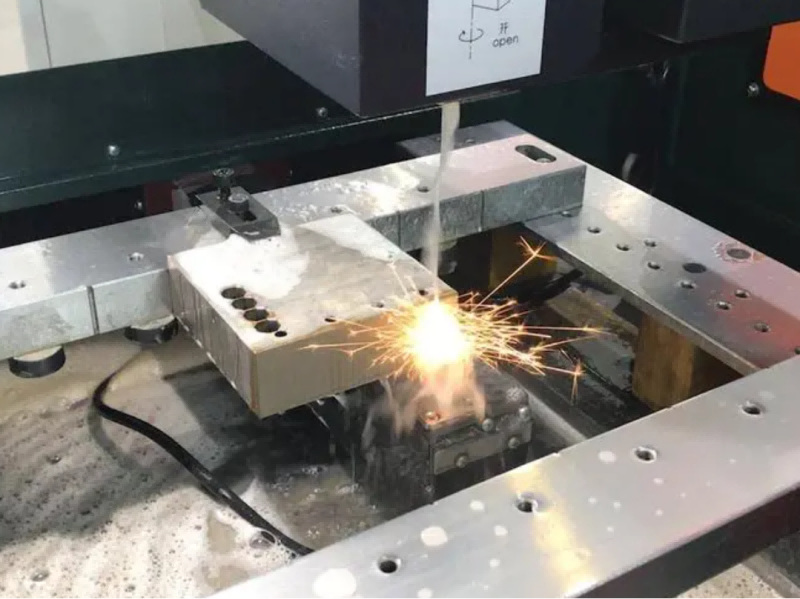

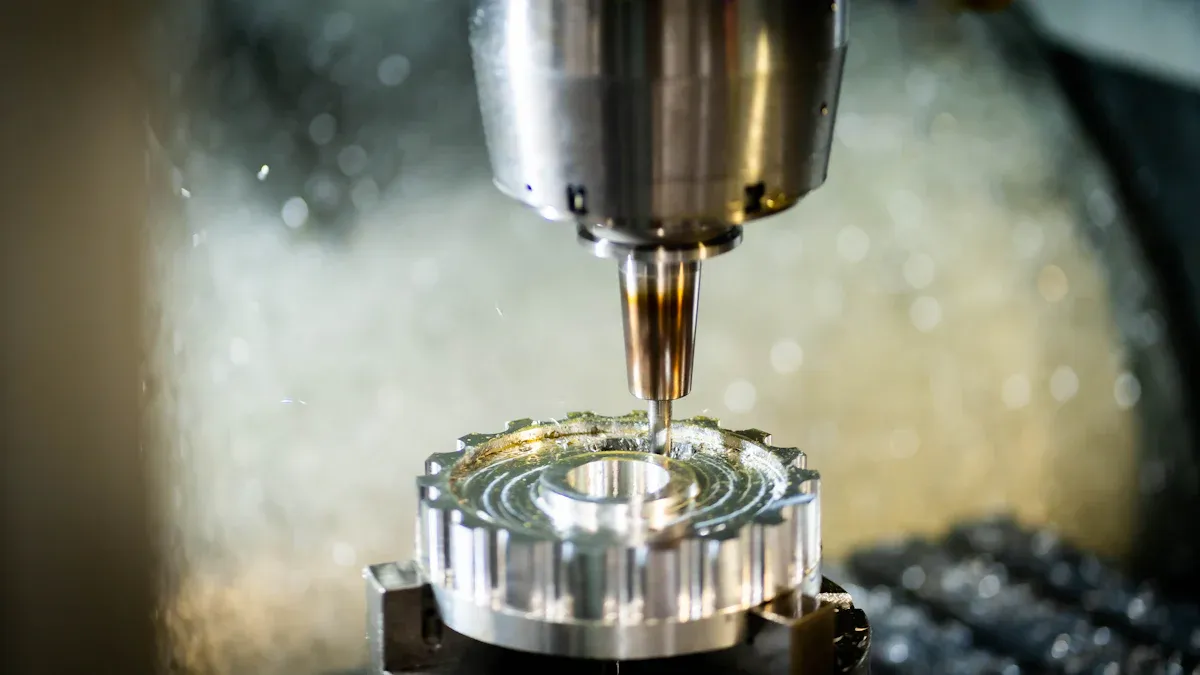

Capabilities & Technology

KEMING uses new machines and tools for investment casting services. The factory has CNC machines and many casting lines. You get exact parts made from stainless steel, aluminum, carbon steel, and special alloys. KEMING makes more than 2,000 tons of castings every year. The team works with over 100 kinds of materials, including stainless and special alloys. You can ask for parts that fit very tight sizes and have smooth surfaces. KEMING follows strict rules like ISO 9001, AS9100, ASTM, and DIN.

| Certification/Standard | Description |

|---|---|

| ISO 9001 | International quality management standard |

| AS9100 | Aerospace quality management standard |

| ASTM | American standards for materials |

| DIN | German standards for precision |

Quality & Customization

KEMING always checks for quality in every step of investment casting services. You get parts that go through many tests. The team looks for surface problems, measures each part, and checks how strong they are. Here are the main steps for quality control.

| Quality Control Measure | Description |

|---|---|

| Visual Inspection | Detects surface defects through careful examination. |

| Dimensional Inspection | Uses tools like CMMs and laser scanning for precise measurements. |

| Non-Destructive Testing (NDT) | Includes X-ray, ultrasonic, and magnetic particle testing to identify internal flaws. |

| Mechanical Property Tests | Assesses hardness and tensile strength to ensure material integrity. |

| Process Controls | Monitors casting parameters to prevent defects during production. |

| Statistical Process Control (SPC) | Maintains consistent quality throughout the production process. |

You can ask for custom investment casting services for your project. KEMING listens to what you need. You can pick from stainless steel, aluminum alloys, carbon steel, ductile iron, bronze, and special alloys. The team helps you pick the best material for your job.

Industry Applications

KEMING helps many industries with investment casting services. You can order parts for cars, planes, medical tools, and boats. Each industry gets special solutions for what it needs.

| Industry | Typical Applications | Key Features |

|---|---|---|

| Automotive | Engine parts, transmission components | Strength, wear resistance, cost-effectiveness |

| Medical | Surgical instruments, implants | Biocompatibility, precision, surface finish |

| Marine | Propellers, pump components | Corrosion resistance, durability |

You get stainless steel for medical tools and implants. You use special alloys for airplane and boat parts. KEMING helps you pick the right investment casting services for your project.

Types of Investment Casting Materials

Properties Comparison

When you pick materials for investment casting, you look at what they can do. Each alloy gives you different levels of strength, rust protection, and weight. You want parts that are very exact and have smooth surfaces. This helps your project work well.

Here is a simple chart comparing the top three alloys:

| Property | Stainless Steel | Aluminum Alloy | Carbon/Low-Alloy Steel |

|---|---|---|---|

| Mechanical Strength | Stronger than aluminum | Not as strong as steel | Not as strong as steel |

| Corrosion Resistance | Great because of chromium | Good, but not in tough places | Not as good as steel or aluminum |

| Weight | Heavier than aluminum | Much lighter | Heavier than aluminum |

Stainless steel alloys protect best against rust. They make strong parts that last a long time, even in hard places. Aluminum alloys help you make light parts that are very exact. Carbon and low-alloy steels are strong and exact for heavy jobs, but they are heavier and do not fight rust as well.

You should choose the alloy that fits your needs. This helps you get the right mix of strength, weight, and rust protection.

Applications Overview

Investment casting materials are used in many jobs. Each industry needs parts that are very exact and fit well. You want alloys that match your job and give good results.

- Gun makers need exact parts for detailed shapes. They use different alloys for each piece.

- Doctors and dentists need very exact tools and implants. Stainless steel alloys work well because they do not rust and keep their shape.

- Lock makers want strong and exact parts. They use alloys that fit tight and last long.

- Food factories use stainless steel alloys for machines. These alloys do not rust and keep things clean.

- Hydraulic and pneumatic machines use alloys like stainless steel and aluminum. These materials help parts work well and fit right.

You make things faster when you pick the right alloy. You get exact parts and do not need much extra work. This saves you time and money.

Future Trends in Investment Castings

Material Innovation

Big changes are coming to investment castings. New materials and technology are being used. The casting process now uses advanced alloys and composites. You can pick lighter options like aluminum and titanium alloys. These materials make parts stronger and help stop rust. Parts last longer because they are tough and strong.

Sustainability is more important now. Many companies use eco-friendly materials and save energy. You see more recycled metals and renewable resources in casting. Research teams work on new superalloy formulas and composites. They also test additives to make the casting process better and parts more exact.

- The casting process now uses:

- Lightweight aluminum and titanium alloys for strong, light parts

- Superalloy blends for tough and durable parts

- Eco-friendly waxes and binders for cleaner casting

- Recycled steel and metals for greener casting

- New molding shell materials for more exact parts

Industry Impact

Many industries are changing how they do casting. Automation and digital tools help make parts more exact and faster. Robots and computer machines make the casting process more precise. You get strong parts with tight tolerances for planes, medical tools, and cars.

The investment casting industry will change a lot soon. There will be more automation, digital design, and focus on being green. Aerospace and medical industries will use more investment castings.

- Sustainability is now very important in casting:

- Most companies use biodegradable waxes and low-impact binders

- Recycled steel and metals help cut down waste

- Over 85% of companies spent more on sustainability in 2023 and 2024

The market is growing fast. The global investment casting materials market will grow at a CAGR of 4.68% through 2025. Growth is even higher in Singapore, Taiwan, and Southeast Asia. The casting process will keep getting better with new superalloys and digital tools.

Modern automation is changing casting everywhere. You get more exact parts, stronger materials, and parts that last longer.

Picking the right material for investment casting is important. It changes how your parts work, how long they last, and if they fit your needs. You can see this in different ways:

| Metric | Description |

|---|---|

| Exceptional Precision | Makes exact copies of hard designs |

| Superior Quality | Follows strict rules for industries |

| Durability | Works well for tough jobs and lasts longer |

| Customizability | Can be made to fit your needs |

KEMING’s team helps you choose the best material. They have helped with baseball bats, bike frames, and ice axes. KEMING has ISO9001 certification and does careful tests. You get parts you can trust. KEMING will help you find the right answer for your next project.

FAQ

What is investment casting?

Investment casting is a way to make metal parts. First, you make a wax model of the part. Then, you cover the wax with ceramic. Next, you melt the wax out. You pour metal into the empty space. This makes strong and detailed parts. Investment casting helps you get the right shape.

Why should you choose investment casting for your project?

You should pick investment casting for very exact parts. It gives you smooth surfaces on your parts. It works well for shapes that are hard to make. You can use many metals with this method. Investment casting saves you time and money.

Which industries use investment casting the most?

Many industries use investment casting. Car makers use it for engine parts. Airplane companies use it for plane parts. Doctors use it for tools and implants. Factories use it for machine parts. Investment casting gives strong parts for many jobs.

How does investment casting compare to other casting methods?

Investment casting gives more detail than sand casting. It also makes smoother parts than die casting. You use it for small or tricky shapes. You can use many alloys with this method. Investment casting helps you get top-quality parts.

Can you customize parts with investment casting?

Yes, you can make custom parts with investment casting. You can pick the design, size, and material you want. Experts help you match your needs. Investment casting helps you get the part you need.