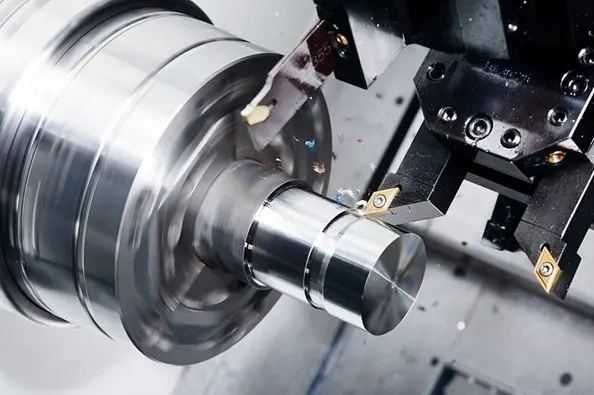

Precision CNC machine tools like those from Kern Microtechnik can machine parts with tolerances as small as ±5 μm and surface roughness Ra not exceeding 0.8 μm. These machines utilize powerful hardware and state-of-the-art control software. Higher Mecanizado CNC accuracy is crucial for industries such as aerospace, medical, and automotive. These fields have extremely high precision requirements to ensure safety and reliability. KEMING employs advanced custom Torneado CNC and milling technologies to ensure superior quality for every part. Not all machining requires ultra-high precision; companies should choose the appropriate machine tool based on project needs.

- CNC machining gives:

- Tolerances as small as ±0.005 inches

- Extremely high precision due to closed-loop feedback

- Excellent surface finish

Principales conclusiones

- The precision of CNC machining is critical for certain industries. Especially in the aerospace and medical fields, where safety and reliability are extremely important.

- CNC machine tools require regular calibration and maintenance to maintain their accuracy and extend their service life, while reducing production errors.

- Choosing the right CNC machine tool depends on the specific requirements of the project, budget, and materials used.

- High-precision CNC machine tools can improve machining speed and quality, thereby enhancing product quality and meaning a higher return on investment.

- Training and supporting operators is crucial to helping them better utilize advanced CNC technology.

Measuring CNC Machines Precision

Accuracy vs. Repeatability

Accuracy and precision are both critical in CNC machining. Accuracy refers to how close a measured value is to the true value. Repeatability refers to whether the measurement result is consistent each time. Precision refers to whether the measured value remains unchanged when repeated measurements are taken. The table below provides some examples to help you understand these concepts:

| Concept | Definition | Ejemplo |

|---|---|---|

| Precisión | How close a measured value is to the actual target value. | A part that always measures 10.00 mm is accurate. |

| Repeatability | The ability to obtain the same measurement value under identical conditions. | A part that always measures 9.90 mm has high precision but low accuracy. |

| Precisión | The degree of consistency of repeated measurement results. | Parts with measured values of 10.05 mm, 9.95 mm, and 10.10 mm are inaccurate. |

| Neither | Not accurate or precise. | Parts with measured values of 9.80 mm, 10.20 mm, and 9.90 mm deviate significantly from the target values and are inconsistent. |

Industry Standards and Tolerances

Industry standards help establish rules for the accuracy and precision of CNC machine tools. These rules focus on the smoothness of machine tool movement and the stability of repetitive operations. They specify maximum permissible errors to ensure that parts are machined correctly every time. The following table lists some commonly used tolerance grades:

| Tolerance Level | Measurement | Área de aplicación |

|---|---|---|

| ±0.001 inches | ±0.0254 mm | General CNC machining |

| ±0.0001 inches | ±0.0025 mm | Critical applications |

| ±0.0005 inches | / | Modern CNC machining |

| 1-5 microns | / | Specialized techniques |

| 1-3 micras | / | Medical device components |

- CNC machining standards help ensure the accuracy of machine tool movements.

- They specify the maximum permissible errors in tool movement and part dimensions.

- High-precision machining typically controls tolerances within ±0.001 inches.

Why Precision Matters

The accuracy of CNC machining determines the quality and reliability of products. Higher accuracy means better performance and higher reliability. Quality checks help ensure accuracy throughout the machining process. New CNC machine tools can detect problems and quickly fix them. This helps maintain consistency in machining results and avoid delays.

- CNC machining requires suitable parts, tools, setup, and maintenance to ensure accuracy.

- Improving machining efficiency can save time, reduce costs, decrease material usage, and facilitate the production of more parts.

- Quality inspection ensures that each part meets stringent standards.

- CNC technology helps manufacture parts with small tolerances and repeatable results.

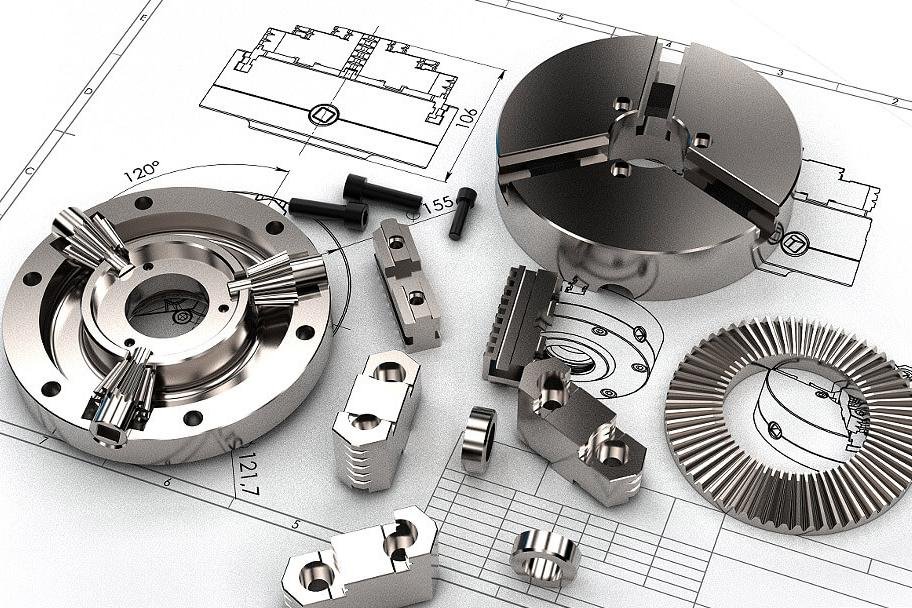

Top Precise CNC Machines

Leading Brands and Models

Many companies manufacture precision CNC machine tools for factories. These machines are used to manufacture parts for the aerospace, medical, and automotive industries. Some brands are renowned for their superior technology and reliability.

- Kern Microtechnik produces machine tools with extremely small tolerances, specifically designed for machining miniature parts.

- DMG MORI manufactures machine tools known for their automation and high precision, used by numerous aerospace and medical companies.

- MAZAK utilizes artificial intelligence to monitor machine tool operation, improving machining accuracy; its machine tools are suitable for the aerospace and defense sectors.

- Okuma machine tools feature thermal compensation, ensuring stability and precision during extended operation.

- Makino uses fiber lasers for cutting, facilitating the machining of intricate parts.

- The Haas EC-400 is known for its excellent quality and reasonable price.

- The DATRON MXCube machine tool is ideal for rapid milling and achieving smooth surfaces.

Many people appreciate versatile machine tools. CNC lathes, CNC milling machines, CNC grinding machines, and CNC drilling machines are all essential in factories. Operators appreciate intelligent features and a robust machine body. Good after-sales service is also crucial for customers.

Key Accuracy Specifications

A precision CNC machine tool must strictly adhere to accuracy and repeatability standards. The table below shows a comparison between the top-of-the-line model and older models:

| Métrica | DC1090A | Traditional VMCs |

|---|---|---|

| Repeatability Accuracy | ±0.005 mm | ±0.01 mm |

| Maximum Spindle Speed | 12,000 RPM | Lower than 12,000 RPM |

| Rated Power | 15 kW | Lower than 15 kW |

| Reduced Machining Time | 25% improvement | N/A |

| Mejor acabado superficial | 30% improvement | N/A |

| Improved Productivity | 40% | N/A |

These data demonstrate that a precision CNC machine tool can produce smoother parts faster. High spindle speeds and powerful motors facilitate milling and turning operations. Advanced machine tools feature thermal compensation and robust frames. These characteristics ensure the machine tools maintain accuracy during extended operation.

Note: Premium machine tools use robust cast iron or steel frames. They are equipped with thermal compensation, linear guides, and a central lubrication system. These features help maintain accuracy and extend the machine tool’s lifespan.

KEMING’s Precision Capabilities

KEMING provides customized CNC turning and CNC milling services to numerous industries. Their machine tools are capable of machining complex shapes and maintaining tight tolerances. The table below shows a comparison between KEMING and other top brands:

| Característica | KEMING’s CNC Services | Leading Global Brands |

|---|---|---|

| Tolerancia | ±0.005 inches (0.13 mm) | Varies by brand |

| Automation | Sí | Sí |

| Control de calidad | Strict inspections | Varies by brand |

| Velocidad de producción | Faster than manual | Varies by brand |

| Part Consistency | High Batch Consistency | Varies by brand |

KEMING utilizes advanced CNC lathes and CNC milling machines. Their team conducts quality inspections on every part. They can process over 50 types of metals and plastics. Their services include additional processes such as anodizing and powder coating. KEMING also possesses CNC laser cutting and CNC plasma cutting machines for handling specialized machining tasks.

KEMING’s machines are capable of producing parts with extremely smooth surfaces. Their meticulous inspection and efficient production processes help customers save time and costs. Many industries trust KEMING’s superior manufacturing performance. Their expertise in turning, milling, grinding, and drilling has provided strong support for numerous projects.

Factors Affecting CNC Machines Precision

Machine Build Quality

The manufacturing quality of CNC machine tools is paramount. High-quality components extend the machine’s lifespan and improve its performance. A robust cast iron or steel frame helps reduce vibration. Lower vibration results in higher machining accuracy. CAD and CAM programming helps optimize toolpaths and reduce tool changes. Simulation software can detect errors before machining parts, thus improving machining efficiency.

- The design and manufacture of CNC equipment helps meet stringent tolerance requirements.

- Proper workpiece setup prevents movement.

- Speed and feed rate are key to achieving accurate results.

Calibration and Maintenance

CNC milling machines require regular calibration and maintenance to maintain accuracy. If the machine is not calibrated, parts may not meet tolerance requirements. Calibration corrects errors that develop over time. Cleaning and tool replacement during maintenance help reduce wear, thus maintaining part accuracy. Regular maintenance ensures machining accuracy and extends the machine’s lifespan.

Tip: Keeping the machine in good condition helps maintain its accuracy and reduces the probability of defects.

- Machines wear out and become misaligned over time.

- A well-designed CAD model and CAM toolpath help guide CNC machine tools.

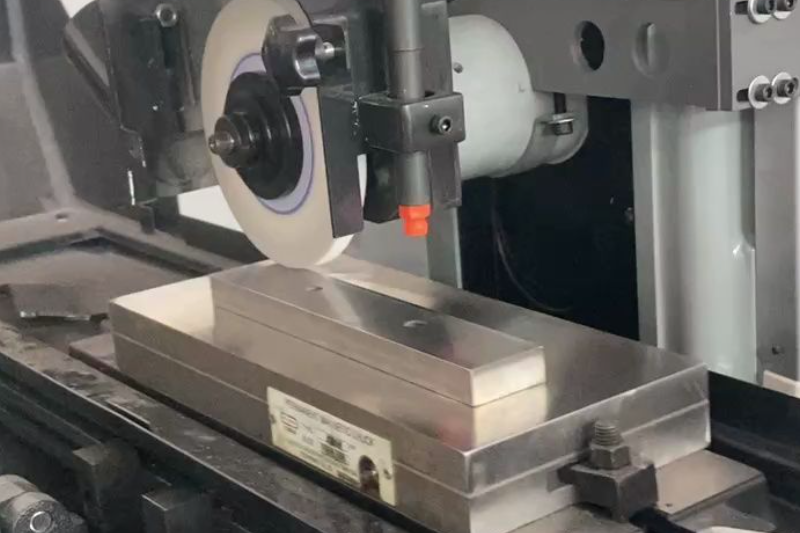

Environment and Materials

Temperature and humidity affect material dimensions during CNC machining. These variations can lead to dimensional inconsistencies in parts. The hardness and elasticity of materials affect machining methods and accuracy. Plastics require special machining processes because high temperatures can cause them to bend. Hard materials require special tools or coatings to achieve high-precision machining. Brittle materials such as ceramics are easily broken and require careful handling.

- Some high-strength materials require advanced methods such as grinding or laser machining.

- The condition and quality of cutting tools affect machining accuracy.

Choosing the Right CNC Machine

Application and Industry Needs

Different industries require different CNC machine tools. Aerospace and medical companies require high-precision machining. Even minute errors can lead to serious problems. Turbine blades on aircraft must fit perfectly to ensure personnel safety. Medical devices such as pacemakers require precise shapes and smooth surfaces to function properly inside the body. Manufacturers should carefully examine the parts they require. They must carefully consider the materials and tolerances for each project. Some machining operations require high-strength spindles to process hard metals. Other operations require specialized motion devices to handle complex shapes. The table below lists important considerations:

| Criterios | Descripción |

|---|---|

| Project Requirements | Check parts, materials, and tolerances. Carbide machining requires high-strength spindles and robust frames. |

| Presupuesto | Consider total costs, including tooling and service. |

| Software | Ensure the machine is compatible with your software. |

| Size and Space | Check if the machine fits your workshop and meets your needs. |

Cost vs. Precision

The price of a CNC machine tool is closely related to its precision. Machines with smaller tolerances are more expensive and take longer to machine parts. These machines require better tooling and skilled operators. The table below compares conventional and high-precision machine tools:

| Factor | Standard Tolerance (±0.1mm) | Tight Tolerance (±0.01mm) |

|---|---|---|

| Machining Time | Normal | 2x – 4x Slower |

| Método de inspección | Calipers, Micrometers | CMM, Laser Scanners |

| Typical Scrap Rate | < 2% | 5% – 15%+ |

| Tooling Needs | Estándar | High-Performance / Custom |

| Habilidad del operador | Skilled Machinist | Senior Specialist |

Companies in the aerospace, automotive, and medical industries invest more upfront. They do this to achieve higher quality and a faster return on investment. These industries typically see returns within two to five years. High-precision machine tools help them produce better products.

User Suitability

Operating the most precise CNC machine tools requires skilled workers. Experienced technicians are well-suited to setting up and using these machines. New users may encounter difficulties with setup or troubleshooting. Manufacturer-provided training and assistance can help users learn more quickly. Excellent support includes technical support, online courses, and training programs. These resources help students and teachers solve problems and ensure the machine operates smoothly.

Tip: Choose a machine with strong support and training. This helps everyone use the machine safely and achieve good results.

Teams focused on quality and training can use advanced CNC machine tools. This helps them produce better products and improve their work.

Precision CNC machine tools have a robust frame. They use special guideways to achieve smooth movement. Advanced control systems help maintain the machine’s precision. DMG MORI, MAZAK, and HAAS Automation are top brands. The table below lists the key characteristics of precision machine tools:

| Característica | Descripción |

|---|---|

| Rigid Machine Structure | The robust frame prevents swaying and contributes to improved accuracy. |

| High-Precision Guide Rails | Special guide rails ensure smooth and precise movement. |

| Advanced Control System | The intelligent control system guarantees machine accuracy even at high speeds. |

KEMING is renowned for its skilled workers and custom designs. They provide excellent service for orders of all sizes. Businesses should choose the appropriate machine based on their project requirements.

- KEMING’s CNC machining services help numerous industries produce high-quality parts.

- Their solutions are suitable for machining a variety of complex parts and materials.