Curious people often wonder what makes the Lost Foam Gießen process special. The answer is in its new way of doing things and its technical benefits. This process is different from regular casting. It uses foam patterns and does not need sand cores. This gives more design choices and makes work faster. The table below shows the main things that make Lost Foam Gießen different:

Merkmal | Beschreibung |

|---|---|

Elimination of Patterns | Uses foam patterns instead of regular patterns and cores. |

Flexibilität bei der Gestaltung | Allows for detailed designs and tricky shapes. |

Kosten-Wirksamkeit | Cuts down on tool costs and saves time making things. |

Improved Surface Finish | Makes fine details and smooth surfaces possible. |

Nachhaltigkeit | Makes less waste and does not use sand cores or binders. |

Experts think Lost Foam Gießen will grow a lot. This is because of new technology and the need for lighter, greener parts. KEMING’s new casting solutions show this change. They make sure every project has good quality and new ideas.

Wichtigste Erkenntnisse

Lost foam casting uses foam patterns, not regular molds. This lets people make lighter and more complex shapes. This process makes less waste and uses less energy. It is better for the environment than sand casting. Parts made this way have smooth surfaces and are very accurate. This means workers do not need to do much finishing work. Lost foam casting saves money, time, and work. It still makes high-quality parts. Car and airplane companies use lost foam casting. They use it to make strong and light parts.

Lost foam casting process and its core differences

Use of foam patterns instead of traditional molds

Lost foam casting is special because it uses foam patterns. Workers make a foam pattern that matches the final part. They use expanded polystyrene (EPS) to shape these patterns. Each foam pattern is light and simple to move. This process lets people make very tricky shapes. Sand casting uses a solid pattern and needs sand cores for hollow spots. Investment casting uses wax patterns that melt, but in lost foam casting, foam patterns turn into gas when metal is poured.

Using foam patterns gives many benefits:

Parts can weigh over 40% less than with old molds.

Making parts is over 40% faster for similar items.

Hard shapes are possible, which old molds cannot do.

This way is also called evaporative pattern casting. Making detailed and light parts gives makers more design choices.

Direct metal pouring and pattern vaporization

In lost foam casting, workers put the foam pattern in a box and cover it with fine sand. When they pour hot metal in, the foam pattern turns to gas right away. The metal fills the empty space left by the foam. This step is not like other casting ways. In sand casting, the pattern is taken out before pouring. In investment casting, the wax melts out before metal is added.

The foam turning to gas changes quality and speed:

Aspekt | Auswirkungen auf die Gussqualität | Impact on Process Efficiency |

|---|---|---|

Foam Thermal Degradation | Changes how fast the mold fills and the metal moves | Less waste and better filling |

Gaseous Degradation Products | Changes back pressure and how the mold fills | Controls gas escape, which changes speed |

Gießtemperatur | Changes what gases form | Needed for good vaporizing and no mistakes |

Pouring speed matters. If it is too slow, the mold may not fill. If it is too fast, mistakes can happen.

Workers must watch the pouring heat to make sure the foam turns to gas and the metal fills every spot.

This step of pouring and vaporizing makes lost foam casting different. It helps make smooth parts and means less extra work is needed.

Comparison with investment casting methods

Lost foam casting and investment casting both use patterns that go away. But they are not the same in materials, steps, or cost. The table below shows the main ways they are different:

Step/Aspect | Lost Foam Casting (LFC) | Sand Casting (SC) | Investment Casting (IC) |

|---|---|---|---|

Mustererstellung | Foam copy of the part, important for being exact. | Solid pattern used to make the mold hole. | Wax pattern that melts away to make the mold. |

Vorbereitung der Form | Fine sand packed around foam pattern for support. | Sand packed around solid pattern, mold must be broken to get the part. | Mold made from wax pattern, then covered with a ceramic shell. |

Pouring Molten Metal | Hot metal poured in, foam turns to gas, leaves a hole. | Hot metal poured in after pattern is removed. | Hot metal poured in after wax melts out. |

Abkühlung und Erstarrung | Metal cools in the mold, keeps its shape well. | Metal cools in sand, may need more work for accuracy. | Metal cools in ceramic shell, often very exact and smooth. |

Oberfläche | Smooth parts, often no extra work needed. | Rough parts, usually need more work after. | Very smooth parts, almost no extra work needed. |

Cost and Tooling | Higher start cost for foam, but good for many parts. | Lower start cost, but more work and more waste. | Higher start cost for ceramic shell, but good for hard shapes. |

Materialeignung | Good for metals like aluminum and magnesium. | Works with almost all metals, even those that melt hot. | Good for exact parts, works with many metals like steel. |

When you look at lost foam casting and investment casting, some things stand out:

Kostenfaktor | Lost Foam Gießen | Feinguss |

|---|---|---|

Materialkosten | Lower because less waste | Higher because materials cost more |

Werkzeug- und Einrichtungskosten | Lower because patterns are simple | Higher because molds are harder to make |

Arbeits- und Verarbeitungskosten | Needs less work | Needs more work |

Lost foam casting uses less material and makes less waste.

The process is quicker and needs fewer workers.

Investment casting is better for very exact and smooth parts, but it costs more and takes longer.

KEMING knows a lot about both lost foam casting and investment casting. Their team knows what each process needs. They use good machines and skilled workers to make sure every foam pattern is right. This helps customers get great results, whether they need easy or hard parts.

Tip: Picking the best casting way depends on the part’s shape, size, and finish. KEMING’s experts can help choose the right process for each job.

Design flexibility in lost foam casting

Creating intricate and lightweight components

Lost foam casting lets engineers make parts with hard shapes. These parts can also be light. Many companies use this process because it can make patterns that other ways cannot.

Lost foam casting makes metal parts with lots of detail.

It keeps sizes very exact, which is needed for many jobs.

The parts come out smooth, so less fixing is needed after.

Integrating internal passages and assemblies

Lost foam casting lets engineers put channels and other parts inside one piece.

They can add cooling paths, oil lines, and strong supports in one step.

The process works with walls that change thickness and hard core shapes.

This helps balance weight, cool better, and make stronger parts.

A car exhaust manifold can weigh 10 kg and have tricky flow paths in one pour. This can cut assembly costs by 15%.

The process lets makers cast curved inside shapes in pumps. This helps pumps work better and last longer.

Reducing machining and post-processing needs

Lost foam casting helps makers save time and money. The process makes parts close to the right shape, so less fixing is needed.

The foam pattern and sand mold make a smooth finish.

Tight sizes mean less extra work.

The process uses less stuff and less energy, so costs go down.

Note: Lost foam casting is special because it can make hard patterns, cut waste, and make work easier.

Efficiency & Cost in Lost Foam Casting

Lower Labor & Energy in Lost Foam Casting

Lost foam casting helps save work and energy. Workers do not need to make or take out sand cores. This means there are fewer steps to do. Less work is needed, and the foundry uses less energy. The table below shows how much can be saved with lost foam casting:

Metrisch | Savings Percentage |

|---|---|

Energieeinsparung | 25% – 30% |

Einsparungen bei der Arbeitsproduktivität | 46% |

Reduzierung des Materialverbrauchs | 7% |

Senkung der Produktionskosten | 20% – 25% |

These numbers mean companies can make more parts with less work. Using less energy is also better for the planet.

Streamlined Production & Faster Turnaround in Lost Foam Casting

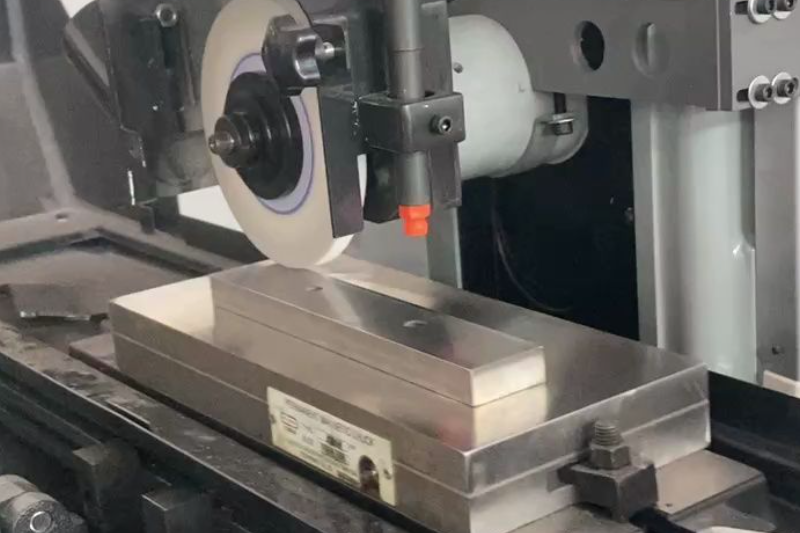

Lost foam casting uses a simple way to make things. Workers can make foam patterns fast with CNC machines or 3D printing. This helps projects start sooner. The process puts many steps together into one. Workers pour metal and make hard shapes at the same time. This saves time for each part. Companies can finish products faster and help customers quickly.

Tip: A simple process helps factories meet tight deadlines and new orders.

Mass Production Benefits of Lost Foam Casting

Lost foam casting is good for making many parts at once. Factories use it to make big transmission casings and heavy gray iron castings. The parts come out strong and have few mistakes. The process can handle big and tricky parts, like an 8.6-ton high-speed press crossbeam. The results stay the same each time. This makes lost foam casting a good choice for making lots of parts. Companies can save money and get good quality, even for hard jobs.

Surface finish and dimensional accuracy benefits

Getting smooth surfaces with fewer problems

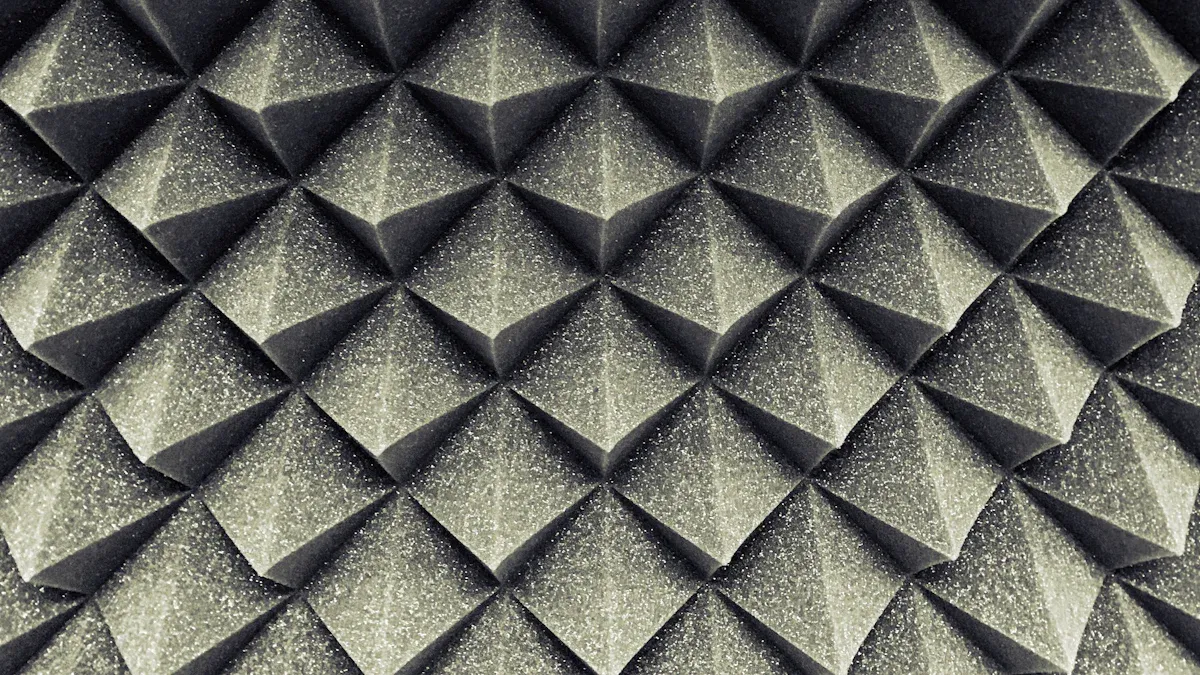

Lost foam casting makes parts with very smooth surfaces. Foam patterns leave a special bead look on the metal. Most parts have a finish between 3 and 6μm. This is smoother than sand casting. Sand casting often needs more grinding or blasting. Lost foam casting also has fewer problems. There are no sand cores, so sand problems happen less.

Tip: Smoother parts mean less time cleaning and finishing.

High accuracy for tricky shapes

Lost foam casting is good for making tricky shapes with high accuracy. The process keeps sizes very close to what is needed. Foam pattern density and pouring heat change how exact the part is. The tables below show how these things matter:

Foam Density (kg/m³) | Oberfläche | Maßgenauigkeit | Energy Consumption |

|---|---|---|---|

16 | Mäßig | Mäßig | Niedrig |

20 | Hoch | Hoch | Mäßig |

24 | Sehr hoch | Sehr hoch | Hoch |

Metall Typ | Optimal Pouring Temperature (°C) | Oberfläche | Maßgenauigkeit |

|---|---|---|---|

Aluminium-Legierungen | 650-750 | Hoch | Hoch |

Stahl-Legierungen | 1400-1500 | Mäßig | Hoch |

Kupfer-Legierungen | 1000-1100 | Hoch | Mäßig |

Lost foam casting helps make both aluminum and steel parts very exact. This is why many industries use it for parts that must fit just right.

Less extra work after casting

Lost foam casting makes parts close to their final shape. Workers do not need to machine, grind, or blast as much. Smooth foam patterns and fine sand mean fewer lines and less flash.

Note: High accuracy and smooth surfaces help companies save money and finish parts faster.

Environmental sustainability of lost foam casting

Lower waste and emissions compared to sand casting

Lost foam casting is better for the environment. Foundries can reuse the casting sand. This helps cut down on waste. Regular sand casting uses sand with chemicals. These chemicals make more waste and can be hard to get rid of. Lost foam casting does not use these chemicals. It makes less solid waste. But, the process can make harmful gases in the air. Factories need good air flow and safety rules. These steps keep workers and nature safe.

Many companies pick lost foam casting. It helps them follow strict environmental rules and keeps more waste out of landfills.

Reduced global warming potential (GWP)

Lost foam casting can help lower global warming. The process uses less energy. This is because it does not need sand cores. Using less energy means fewer greenhouse gases go into the air. Factories that use lost foam casting follow important rules. These rules help control pollution and waste. The table below lists some main rules for lost foam casting:

Regulation | Zweck |

|---|---|

Clean Air Act | Controls air pollution. |

Resource Conservation and Recovery Act | Manages waste. |

Energy Policy and Conservation Act | Promotes saving energy. |

KEMING follows these rules. They make sure their casting is safe for people and the planet.

Use of recyclable materials in the process

Lost foam casting uses materials that help the environment. Many factories use foams that break down and alloys that can be recycled. These materials help stop pollution and save resources.

KEMING works hard to make casting better for the environment. The company uses new ways and good materials. Their team tries to make less waste, save energy, and protect nature for the future.

Lost foam casting is special because it is exact and saves energy. It makes parts that fit well and have smooth surfaces. The process also makes less waste and uses less energy. Many businesses use lost foam casting for these reasons:

Industrie | Anwendungen |

|---|---|

Automobilindustrie | EV motor housings, lightweight chassis components |

Industrielle Maschinen | Pumps, valves, brackets, and casings |

Aerospace and Defense | Complex engine parts |

Agriculture Equipment | Durable, intricate components |

KEMING helps companies make hard and strong parts. Their casting solutions are good for the planet and make less waste.

FAQ

What materials work best with lost foam casting?

Aluminum and magnesium alloys are the top choices. Factories also use cast iron and some steels. The process works best with metals that melt at lower heat. Each metal gives different strength and surface finish.

How does lost foam casting help reduce waste?

Lost foam casting uses patterns that turn into gas. Workers can use the same sand again and again. The process makes less leftover metal. Factories do not need chemical binders, so there is less waste.

Can lost foam casting make large parts?

Yes, lost foam casting can make small and large parts. Factories use it for engine blocks and pump housings. It is also used for heavy machines. The process can handle tricky shapes, even for big castings.

In welchen Branchen wird das Lost Foam Casting am häufigsten eingesetzt?

In der Automobilindustrie, im Maschinenbau und in der Luft- und Raumfahrt wird das Lost Foam Casting häufig eingesetzt. Diese Branchen benötigen starke, leichte und detaillierte Teile. Auch die Landwirtschaft und die Schifffahrt nutzen dieses Verfahren.