Innovation is transforming sand casting manufacturing. Companies are leveraging new technologies such as automation to meet evolving demands. The industry is listening to its customers, responding to global competition, and committing to environmental improvements. Recent research indicates that additive manufacturing can reduce waste and save energy. The table below illustrates how new technologies can help improve casting accuracy and achieve environmental goals:

| Tecnología | Beneficio |

|---|---|

| Impresión 3D | Higher Precision |

| Automation | Less Waste |

| Fabricación aditiva | Energy Efficiency |

Recent advancements in sand casting technology have helped increase production speed, enable more complex shapes, and create a cleaner environment. Adopting new technologies provides businesses with a significant competitive advantage.

Principales conclusiones

- Innovations in sand casting utilize technologies such as 3D printing and automation, which help improve production speed and precision. Customers demand higher quality products, so manufacturers are committed to improving product quality and efficiency, and making greater use of digital tools. Environmental protection is paramount. Businesses strive to reduce energy consumption and waste. Data helps foundries quickly identify and solve problems. They can also react quickly when the market changes. 3D sand printing technology enables the rapid creation of complex shapes and the testing of ideas, saving time and materials.

Drivers of Innovation in Sand Casting

Customer Demands and Market Trends

Manufacturers have noticed that customers want better products. Customers buying metal parts demand extremely high precision, crucial for industries like automotive and aerospace. Businesses also want faster delivery times and increased efficiency. Many are leveraging automation and digital tools to achieve this. CNC mold modeling and simulation software makes production more precise and faster. Digital integration and AI-driven processes are transforming the sand casting industry. Emerging countries are driving market growth, placing a strong emphasis on environmental protection.

- Customers want parts manufactured with superior quality.

- Automation and digital tools help businesses improve efficiency.

- CNC mold modeling and simulation software makes production more precise.

- Emerging countries are driving market expansion.

- Environmental protection is paramount.

KEMING meets these demands through rigorous quality control and flexible production methods. Their precision casting services adhere to strict specifications and cater to the needs of each customer.

Competitive Pressures and Globalization

Globalization brings both challenges and opportunities. Businesses need to address supply chain issues such as tariffs and port congestion, as well as the challenges posed by the international landscape. Many large companies now want to conduct casting closer to home. Local companies may have an advantage in the short term, but to succeed globally, they must adopt new technologies and comply with emissions regulations.

| Factor | Descripción |

|---|---|

| Supply Chain Disruptions | Tariffs and port congestion have prompted businesses to seek local casting services. |

| Technological Advancements | Automated and digital casting has made production processes faster and more flexible. |

| Competitive Dynamics | Winning depends on technology, scale, and compliance with emissions regulations. |

KEMING maintains its leading position by acquiring new equipment and training its workforce. Their adaptability helps them maintain an advantage in the international market.

Sustainability and Environmental Goals

Sustainability is paramount in sand casting. Companies are committed to reducing waste and conserving energy. Many use specialized systems to assess their effectiveness. Material reuse and improved design help protect the planet. Sand can be reused repeatedly, making the process ideal for recycling. These initiatives contribute to a carbon-neutral future and result in lighter, fewer parts.

- Reducing waste and conserving energy are key.

- Specialized systems help track green goals.

- Reuse of materials and sand is widespread.

- Improved design means fewer parts and less waste.

KEMING pioneered green methods and energy-efficient tools. Their environmental focus benefits not only their customers but also the planet.

Advances in Sand Casting Technology

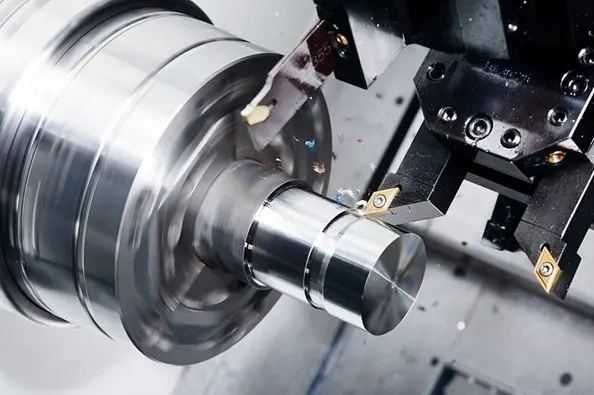

Automation and Process Control

Today, sand foundries employ new automation and process control systems. These systems help companies manufacture parts with greater precision. Automated molding lines meticulously shape each mold. Robots clean castings to meet high quality standards. Core-making machines create robust and precise cores for each casting. Laser scanning inspects finished parts with clear 3D scan images, ensuring each product meets design requirements.

- Advanced molding lines contribute to improved mold precision.

- Robots handle part cleaning, maintaining high quality.

- Core-making machines create robust and precise cores.

- Laser scanning provides clear 3D images for quality inspection.

Real-time monitoring is crucial for these improvements. Workers can identify and resolve problems early. Automation of sand mixing and robotic pouring also helps improve efficiency and reduce errors. These new tools increase productivity, improve product quality, and reduce errors.

Data-Driven Optimization

Data-driven optimization is transforming the way foundries operate. Machine learning models analyze vast amounts of process data, uncovering patterns that might be missed by the human eye, helping teams nip defects in the bud before they occur. Real-time monitoring provides rapid feedback, enabling workers to adjust settings immediately.

This approach produces more qualified parts, reduces waste, and saves costs by minimizing scrap and rework. Companies adopting data-driven optimization outperform those using traditional methods. They can respond quickly to changes in demand or material quality, giving them a competitive edge.

Simulation and CAD Integration

Simulation and modeling tools have revolutionized sand casting design. Simulation software allows engineers to understand the entire casting process before actual production, observing the flow and hardening of metal within the mold. This helps them identify and resolve problems early, saving time and costs.

- Simulation software contributes to producing castings of higher quality with fewer errors.

- CAD technology enables engineers to create accurate 3D models, resulting in better designs.

- Engineers can quickly test and modify designs on a computer.

- CAD facilitates better team communication, making work smoother.

Simulation and modeling mean fewer costly mold changes. Engineers can make modifications on a computer without physically being on the factory floor. This leads to faster and lower-cost production. The combined use of CAD and simulation technologies means that every casting begins with a good design. Companies can now manufacture shapes that were previously difficult to produce. These new tools help companies produce better products faster.

Companies using these new tools are leading the industry. They are able to achieve higher quality, lower costs, and faster completion of work. Real-time monitoring, data-driven optimization, and simulation tools set a new standard for success.

3D Sand Printing and Additive Manufacturing

3D Printed Sand Molds

3D sand printing is revolutionizing mold making in foundries. This technology enables businesses to create sand molds of a wide variety of new shapes. Engineers can now easily create chamfers and thin walls. 3D printing helps foundries create complex shapes for sand casting in just a few days. They no longer need to wait for old molds. This means they can work faster and change designs quickly. 3D sand printing also facilitates the manufacture of delicate metal parts. This saves manufacturing teams time and money.

| Ventaja | Descripción |

|---|---|

| Design Freedom | Make digital modifications easily and precisely to handle complex designs. |

| Reduced Costs | No expensive molds are needed, saving businesses money. |

| Quick Turnaround | Mold making time is reduced from weeks to hours. |

| Mejora de la eficiencia | All projects can be completed faster and more economically. |

| Reduced Material Waste | Leftover materials can be reused, reducing waste. Design drawings are stored on the computer. |

Rapid Prototyping Benefits

Additive manufacturing using 3D sand printing technology significantly improves the efficiency of rapid prototyping. Teams can quickly test new ideas and see results in just a few days. They don’t have to wait weeks for new molds. This speed advantage helps companies solve problems earlier and launch products faster. Additive manufacturing methods also save costs because they eliminate the need for traditional molds. Companies can make modifications and retest at any time without slowing down production.

- More complex design options

- Rapid testing before mass production of parts

- Significant cost savings with fewer molds

- Faster production speeds for quicker product delivery to customers

- Reduced waste, benefiting environmental protection

Design Flexibility and Lead Time Reduction

3D sand printing gives more design choices than ever before. Engineers can make shapes that were too hard or expensive before. They can change designs on the computer and print new molds right away. This cuts wait times from weeks to just days. Additive manufacturing removes many old steps, so teams can change things quickly. Companies make less waste and use less energy, which helps the earth. A German foundry saw 40% less waste sand and used 25% less energy. Making things in more places also lowers shipping costs and pollution.

3D sand printing is leading the way in modern manufacturing. It helps companies work faster, make better things, and care for the planet. Companies using this technology are ahead in sand casting innovation.

Materials and Sustainability in Sand Casting

Eco-Friendly Binders and Recyclable Sands

Today, foundries are choosing more environmentally friendly binders and sands. They use organic binders made from substances like starch and sugar. These binders produce less pollution, helping to keep the air clean. Because these materials are not as harmful as older materials, it’s also safer for workers. Organic sand binders work in many ways. They come from renewable resources, making them good for the planet. They strengthen molds and reduce dust, making recycling easier. They also help foundries create more detailed castings and help molds separate better, reducing errors.

- They use renewable materials, making them more environmentally friendly.

- Molds are stronger and produce less dust, making recycling easier.

- Castings can have more detail, and molds are easier to remove, resulting in fewer problems.

Green sand casting allows foundries to reuse the same sand repeatedly. This saves costs and reduces waste. It also helps companies adapt quickly when different parts or metals are needed.

Energy-Efficient Furnace Technologies

Energy-saving furnace technology helps foundries become more environmentally friendly. Foundries are adopting new methods of heating metals, such as induction heating and plasma heating. These systems heat metals quickly and maintain precise temperatures. Choosing the best furnace and using good insulation materials prevents energy waste, thus saving costs.

| Tipo de tecnología | Descripción |

|---|---|

| Advanced Heating Technologies | Induction heating and plasma heating enable fast and precise heating. |

| Energy Waste Reduction | Faster heating speeds and better control mean less energy waste. |

| Furnace Efficiency Impact | The furnace body and insulation materials used affect the amount of energy required. |

These changes help foundries comply with strict pollution regulations, thus protecting the environment.

Sand Reclamation Systems

Modern foundries utilize specialized sand recycling systems. These systems can clean and reuse sand more than thirty times. This means less sand is sent to landfills and reduces the need for new sand. More efficient sand recycling also saves costs and helps protect the planet.

- Closed-loop systems reduce waste generation, thus saving costs.

- Inorganic binders and new release agents reduce harmful emissions.

- Landfill costs are constantly rising, making waste reduction even more important.

New regulations require foundries to adopt more environmentally friendly production methods. By complying with these regulations, companies demonstrate their commitment to the planet and are at the forefront of safe production practices.

Industry Applications and Measurable Benefits

Automoción y aeroespacial

The automotive and aerospace industries require robust and durable high-quality components. These components must be able to function reliably in harsh environments. Advanced sand casting technology can manufacture steel parts for engines and frames. These parts are strong yet lightweight. Lighter parts help cars and aircraft save fuel and contribute to meeting safety regulations. KEMING utilizes sand casting technology to customize parts for each project.

| Beneficio | Descripción |

|---|---|

| Relación coste-eficacia | Advanced sand casting technology reduces manufacturing costs. |

| Adaptabilidad | Complex shapes can be manufactured for a variety of automotive and aerospace parts. |

| Weight reduction | Lighter steel parts improve fuel efficiency. |

| Fuel efficiency | Lighter vehicles consume less fuel, saving costs and reducing emissions. |

- The company can provide accurate quotes.

- Product quality is improved.

- Design costs are reduced.

- Parts are manufactured faster.

- Company profitability is enhanced.

Aerospace companies require smoother, more precise steel castings. This is crucial for safety and performance. Using green sand molding materials reduces waste and protects the environment.

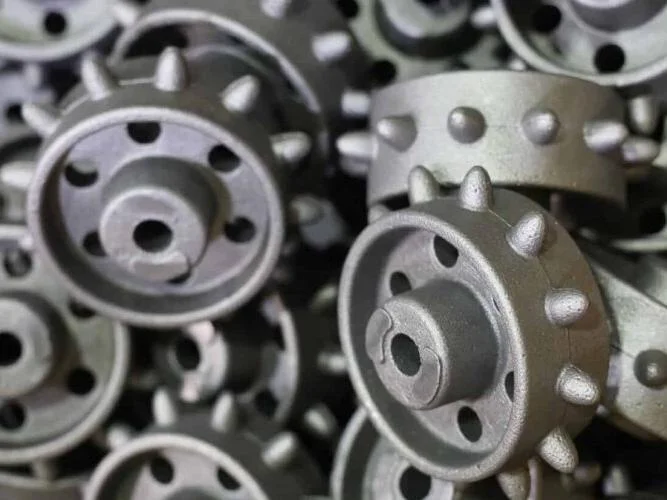

Construction and Mining

The construction and mining industries require durable parts. Sand casting technology can produce steel and iron parts for pumps and tools. New alloys and more advanced control technologies make these parts stronger and more durable. Automation helps ensure consistency in parts. New mold materials can reduce defects.

- Lightweight alloys and new materials help improve machine performance.

- Automation makes work faster and more consistent.

- Modern mold technology produces better parts.

- Continuous research constantly improves materials.

KEMING Company can manufacture strong and durable steel parts for these industries.

Custom and Small Batch Production

Now, producing customized parts in small batches has become easier and more economical. 3D printing technology facilitates the rapid manufacturing of molds. Companies can quickly modify designs and produce on demand, saving time and reducing waste. This also helps in better utilization of materials.

- Computer-aided design allows for rapid design modifications.

- Companies produce parts on demand, reducing waste.

- Materials are utilized efficiently, reducing losses.

KEMING provides flexible casting services for special projects. Their expertise in steel casting means that every customer receives the right parts, regardless of quantity.

Companies adopting advanced sand casting technology gain a competitive advantage. They can produce better products, save costs, and protect the environment.

| Sector | Descripción de la aplicación |

|---|---|

| Automoción | Makes light, strong engine parts for better cars and fuel use. |

| Aeroespacial | Builds tough, complex parts like turbine blades for safety. |

| Marina | Makes parts for ships that do not rust in sea water. |

| Rail | Makes strong, exact train parts for heavy loads. |

| Agricultura | Makes tough parts for farm machines that last outside. |

| Médico | Makes safe parts for surgery tools and implants with smooth surfaces. |

In recent years, sand casting technology has made significant progress. Companies are using 3D printing and real-time monitoring technologies to produce higher-quality parts. They are also using sand recycling technology to reuse sand and reduce waste. These new technologies help save energy and improve product quality. More and more companies are opting for environmentally friendly sand because it is more environmentally friendly. Experts predict that digital simulation and automation technologies will be more widely used in the future. New materials will also help produce higher-quality castings. To succeed, companies should choose partners with advanced technology and strict quality control systems. KEMING provides advanced casting solutions to help businesses grow and meet future challenges.