Fresado CNC Mecanizado y Mecanizado de torneado CNC Services utilize advanced computer-controlled equipment to produce highly precise parts from a variety of materials. These CNC Milling Machining Services, along with CNC Turning Machining Services and Railroad Castings Manufacturing, are essential for specialized applications across multiple industries. CNC Milling Machining Services are known for delivering custom components with exceptional accuracy, making them a top choice for businesses seeking reliability and versatility. The machining services industry is projected to grow by USD 18.84 billion from 2024 to 2029. Additionally, the global CNC market was valued at approximately USD 67.5 billion in 2023 and is expected to reach USD 80.4 billion by 2028.

Principales conclusiones

CNC machining services use new technology to make exact parts from many materials. These services are important for many businesses. Choosing the best material for CNC machining can save money and make parts work better. You can pick from materials like aluminum, stainless steel, and plastics. CNC machining is flexible for both small and big jobs. This lets companies make custom parts quickly and still keep good quality. Quality checks are very important in CNC machining. Skilled workers use strict tests to make sure every part is made well. Fast work is a big advantage of CNC machining. Most jobs finish in 7 to 15 days. This helps companies meet short deadlines.

CNC Milling Machining Services Overview

Core Processes: Milling, Turning, Drilling

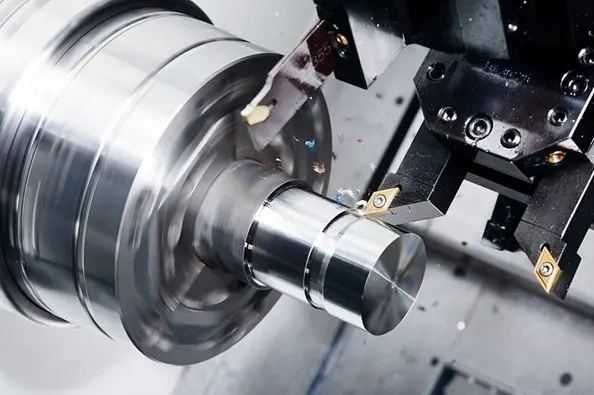

CNC Milling Machining services use three main steps: milling, turning, and drilling. Each step helps shape and finish parts for many industries. Milling uses a spinning tool to cut away material from a still piece. This makes it possible to create tricky shapes and details. Turning spins the part while a tool cuts off material from the outside. This is good for making round parts. Drilling uses a spinning drill bit to make holes in the part. This is important for putting holes in the right place when making things.

Proceso | Función | Aplicación |

|---|---|---|

Torneado CNC | Subtractive process where a workpiece is rotated and material is removed from the exterior. | Commonly used for cylindrical parts in industries like automotive and aerospace. |

Fresado CNC | Subtractive process where a rotating cutting tool removes material from a fixed workpiece. | Used for creating complex shapes and features in various materials, widely in aerospace and automotive. |

Taladrado CNC | Produces cylindrical holes in a workpiece using a rotating drill bit. | Essential for accurate hole placement in manufacturing and construction industries. |

CNC Milling Machining services can make parts very exact. Milling can be accurate to about 0.005 inches for metals. Turning can be accurate to about 0.010 inches for plastics. Drilling can be as exact as 0.002 inches. These skills make CNC Milling Machining a good choice for jobs that need very exact parts.

Machine Types: 3-Axis to 5-Axis

Modern CNC Milling Machining services use special machines with more than one axis. These machines can make very detailed and exact parts. The kind of machine used decides how tricky and exact the part can be.

CNC Machine Type | Capacidades | Complejidad |

|---|---|---|

3-Axis | Suitable for simple tasks, planar milled profiles, drillings, and threaded holes. | Lower complexity |

4-Axis | Enhanced capabilities for complex geometries, reduces multiple setups. | Complejidad moderada |

5-Axis | Highest precision, can handle intricate details and complex parts. | Highest complexity |

3-axis CNC machines are best for easy parts and flat surfaces. They need someone to set them up again for different sides.

4-axis CNC machines have an extra spinning part. This helps make harder shapes and means less setup is needed.

5-axis CNC machines are the most exact and flexible. They can make very detailed parts and handle hard designs easily.

KEMING uses these machines to make custom CNC Milling Machining parts for both samples and big orders. Now, people can get fast quotes, order online, and get quick samples. This helps clients start new projects faster.

Materiales utilizados

CNC Milling Machining services can use many types of materials. The material picked changes the price, how fast the part is made, and how well it works. Some common materials are metals, plastics, and special alloys.

Aluminio

Acero inoxidable

Acero al carbono

Latón

Titanio

Magnesio

Cobre

Acero aleado

PEEK

ABS

Acetal

Nylon

Polycarbonate

PVC

High- and Low-Density Polyethylene

The material chosen affects how much the project costs and how long it takes. Materials that are easy to cut and easy to find help save money and time. Picking the right material makes sure the part works well without costing too much.

KEMING can work with many materials to pick the best one for each job. They can make light aluminum parts or strong stainless steel parts. Their skill with different materials means every part meets high quality and what the client wants.

Tip: Picking the best material for CNC Milling Machining helps the part work better and keeps costs and wait times low.

How CNC Machining Works

From Design to Production

Turning an idea into a finished CNC part is a step-by-step process. Engineers start with a digital design made in a CAD program. This design is the plan for making the part. KEMING helps clients by giving advice to make the design better for CNC Milling Machining. This can help save money when making the part.

The main steps from design to production are:

Make a CAD file that shows what the part looks like.

Use CAM software to turn the CAD file into instructions for the machine.

Pick the right CNC machine for the part and material.

Set up details like how fast to cut and where the tool goes.

Arrange the steps to make the part quickly.

Run a test to find mistakes or crashes.

Finish the part by cleaning or adding final touches.

Most CNC parts go from design to finished product in 7 to 15 days. Simple parts can be done in about a week. Harder parts may need two or three weeks. KEMING’s fast prototyping and online quotes help clients get started quickly.

Tip: Getting advice early on the design can help avoid expensive changes later.

Programming and Setup

Programming and setup are very important in CNC machining. Skilled workers use special software to turn the design into code the machine can read. Some popular programs are Mastercam, Fusion 360, and Solidworks. These programs help make clear instructions for the CNC machines.

The main programming languages are G Code and M Code. G Code tells the machine how to move and how fast to go. M Code controls things like changing tools and turning on coolant. Technicians check these codes to make sure everything is correct.

Setup time depends on how big and hard the job is. For very small batches, setup can take almost all the time. For big batches, setup is much less. The table below shows how setup time changes with batch size:

Lot Size Type | Setup Time Percentage | Cycle Time Percentage |

|---|---|---|

Very Small Lot Size | 90% | 10% |

Very Large Lot Size | 10% | 90% |

Easy setups may only take a few minutes. Hard jobs with lots of tools or big machines can take an hour or more. KEMING’s team works hard to keep setup time short so clients get their parts faster.

Garantía de calidad

Quality assurance makes sure every part is made well. KEMING uses many steps to keep quality high during CNC Milling Machining.

The team checks each order to know what the project needs.

They inspect the first part to see if it matches the design.

They check parts during production at important times.

They look at all parts before shipping them out.

Special tools help with these checks. Coordinate Measuring Machines (CMMs) measure parts very accurately. Optical comparators let workers see if shapes are correct. Surface profilometers check if surfaces are smooth.

Other methods include ultrasonic testing, X-ray inspection, and magnetic particle inspection. These help find hidden problems inside the material. KEMING also uses real-time monitoring and data tools to watch quality as parts are made.

Note: Teams always try to get better at quality assurance. They learn from each job and make changes to do even better next time.

Benefits of CNC Machining

Precision and Accuracy

CNC machining is known for being very exact. Machines follow the instructions in the program closely. This means there are fewer mistakes from people. Workers do not have to use their hands for each part. Instead, machines use automation to make sure every part is the same as the design.

CNC machining uses automation, so there are fewer errors.

Tool paths are set ahead of time for steady results.

Machines do the same steps, so parts all match.

Tolerances show how close a part is to the right size. CNC Milling Machining can make parts within ±0.010 inches (±0.25 mm) for most jobs. Some machines can be as exact as ±0.0025 mm. That is about as thin as a quarter of a hair. The table below shows common tolerances for different jobs:

Manufacturing Process | Standard Tolerance | Typical Materials | Aplicaciones |

|---|---|---|---|

Fresado CNC | ±0.010″ (±0.25 mm) | Aluminum, Steel, Copper | Metal housings, precision parts |

Torneado CNC | ±0.010″ (±0.25 mm) | Metales diversos | Shafts, cylindrical components |

Multi-axis Machining | ±0.010″ (±0.25 mm) | Complex geometries | Aerospace, medical devices |

Note: Tolerances can be different for each machine, but most new CNC machines meet tough rules.

Efficiency and Speed

CNC machining helps make things faster and better. Machines use computers to pick the best way to cut and finish parts. This makes each part take less time to make.

Automated steps help make parts faster and better.

CNC programs test the best ways to work and save material.

Machines can run all day and night for big orders.

Set instructions help make parts quickly and correctly.

How long it takes to make a part can change. Easy parts might be done in a few hours. Hard parts can take weeks if they need special setups or tough materials.

Tip: Automated CNC methods help companies fill big orders fast and keep making good parts.

Customization and Scalability

CNC machining is flexible for small or big jobs. Companies can make just one part or thousands without changing much.

CNC machining works for single samples or big batches.

Every part is made with the same care and quality.

Making more parts is easy, so there are fewer delays and lower costs.

The table below shows how costs change when making more parts:

Descripción de las pruebas | Key Points |

|---|---|

Economies of Scale | Making more parts lowers the cost for each one. |

Reducción de costes | Big orders save money on materials and work. |

Costes iniciales | Large runs cost more at first but less for each part. |

Callout: CNC Milling Machining can change to fit new needs, so it is a good choice for custom and growing jobs.

Applications of CNC Machining

Industrias atendidas

CNC machining helps many industries that need exact parts. Companies use these services to follow strict safety and quality rules. The main industries that use CNC machining are:

Industria médica: Hospitals and clinics need special implants and tools for surgery. These parts must be very safe for patients.

Industria aeroespacial: Airplane makers need parts that work in tough heat and pressure. Each part must fit and work just right.

Automotive and Transportation Industries: Car companies use CNC machining for engine blocks and other key parts. These parts help cars run safely and well.

Note: CNC machining also helps electronics, plumbing, and sports equipment makers by making custom parts for their needs.

Typical Parts and Products

CNC machining makes many types of parts, from tiny to large. Machines can make parts up to 40 inches long and 20 inches wide. Some machines can hold up to 2,000 pounds. Special tools can make features as small as 0.005 inches wide.

Industria | Ejemplos de piezas producidas |

|---|---|

Aeroespacial | Aircraft components, engine parts, body panels, doors |

Electrónica | Printed circuit boards, heat sinks, enclosures, connectors |

Médico | Surgical instruments, implants, prosthetics, dental components |

Plumbing | Valve housings, pipe connectors, union fittings, custom couplings |

Toy and Recreational | Parts for jet skis, boats, ATVs, golf carts |

Factories use CNC machining to make engine blocks, airplane parts, and dental implants. The technology also helps with quick testing of new designs. This lets companies make new products fast and keep up with changes.

Tip: CNC machining can make both easy and hard shapes, so it is a great choice for many industries.

Choosing a CNC Machining Provider

Experience and Capabilities

Picking a CNC machining provider with lots of experience helps get better results. Providers who have worked for many years know how parts work. They can find problems early and give advice during design and making. This advice often makes the final part better.

Experienced providers know how to keep track of changes.

They give Design for Manufacturability (DFM) help to find problems before work starts.

Their engineering help can save time and money by suggesting changes.

A good provider usually has special certifications that show they are experts:

ISO 9001: Focuses on quality and making customers happy.

AS9100: Adds rules for aerospace and risk control.

ISO 13485: Used for making medical devices and following rules.

ISO 45001: Focuses on safety at work and checking for risks.

Tip: Providers who work with clients early can find risky designs and suggest ways to fix them.

Normas de calidad

Quality standards are very important in CNC machining. Providers should use new, high-quality machines to make sure parts are right every time. They must also follow strong quality rules.

Certificación | Importancia |

|---|---|

AS9100D | Has rules for quality management systems. |

ISO 9001 | Makes sure products and services meet what customers want. |

Providers should use special inspection tools like coordinate measuring machines (CMMs) and optical comparators. Checking and fixing tools often keeps things accurate. A Quality Management System (QMS) like ISO 9001 helps keep work the same each time.

Tests and checks happen at every step.

Any mistakes get fixed right away to keep quality high.

Training helps workers follow the newest quality rules.

Note: Always trying to get better and checking work often helps providers make good parts every time.

Customer Support

Good customer support makes the best CNC machining providers stand out. Fast answers and custom help let clients meet tight deadlines and solve problems.

Aspecto | Descripción |

|---|---|

Fast Response Times | Quick delivery, even when time is short. |

Custom Support | Help made just for each client’s needs. |

Strategic Partnerships | Focus on building strong, long-lasting relationships. |

Providers often offer quick parts in just a few days and faster service if needed. They work closely with clients to make sure everything is right. Feedback systems let clients share ideas, and real-time updates help fix problems fast.

Clear talk from start to finish builds trust.

Reliable timing and flexible help make relationships stronger.

Surveys and feedback after projects help make service better next time.

Callout: Providers who care about long-term partnerships always give good quality and keep clients coming back.

CNC machining services use special machines to make parts very exact. These services give many good things:

They make parts with great detail.

They finish parts quickly for short deadlines.

They can make custom parts for special jobs.

Lots of industries use CNC machining because it works well. People should pick providers who have lots of experience. Good providers check quality and help customers.

Tip: Picking the best CNC machining partner helps companies get the right parts for their projects.

PREGUNTAS FRECUENTES

What is the main advantage of CNC machining?

CNC machining is very exact and does the same thing each time. Machines use set instructions to make parts. This helps every part look just like the plan.

Which materials can CNC machines process?

CNC machines can cut metals like aluminum and steel. They also work with plastics such as ABS and nylon. This means many businesses can use CNC machines.

How fast can CNC machining deliver parts?

Most CNC jobs are done in 7 to 15 days. Easy parts can be finished in less than a week. Harder parts might take longer to make.

Can CNC machining make custom parts?

Yes. CNC machining can make special parts from computer designs. It works for just one part or for making many at once.